Method for reducing coking materials of ethylene cracking furnace

A technology of ethylene cracking furnace and coke, which is applied in cracking, non-catalytic thermal cracking, petroleum industry, etc. It can solve the problem of unable to remove the high polymer entrained by dilution steam, and achieve the effect of avoiding coking and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

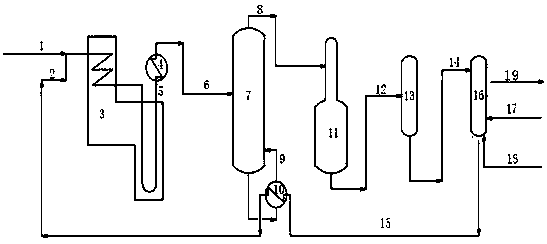

[0024] In the invention, a process water extraction and rectification tower is added after the process water in the process water stripping tower is discharged, and trace high polymers in the process water are removed by an extraction and rectification method.

[0025] The production scale of the ethylene plant is 115,000 tons / year, and the process water treatment capacity entering the process water extractive distillation tower is 28.0 tons / hour. When the gas phase velocity of the process water extractive distillation tower is 0.10 cm / s and the dispersed phase velocity is 0.50 cm / s, the gas holdup is 0.04% and the liquid holdup is 0.25%; the process water extractive distillation tower is packed with bulk packing. The operating temperature of the tower is 70°C at the top of the tower, 110°C at the bottom of the tower, 0.15MPa at the operating pressure (absolute pressure), 140°C at the steam operating temperature, 0.20MPa at the operating pressure (absolute pressure), and the ex...

Embodiment 2

[0027]Same as Example 1, only the operating conditions of the process water extractive distillation column are changed. When the gas phase velocity of the process water extractive distillation tower is 0.05 cm / s and the dispersed phase velocity is 0.30 cm / s, the gas holdup is 0.02% and the liquid holdup is 0.15%; the process water extractive distillation tower is packed with bulk packing. The high polymer contained in the process water entering the process water extractive distillation tower is 50.0mg / L, and after extraction and rectification separation, the high polymer contained in the process water flowing out of the process water extractive distillation tower is only 0.4mg / L, thus During the 3-5 year normal operation period of the entire ethylene unit, coking did not occur in the convection section of the cracking furnace, and the operation period of the cracking furnace was extended to 90 days.

Embodiment 3

[0029] Same as Example 2, only the operating conditions of the process water extractive distillation tower are changed. When the gas phase velocity of the process water extractive distillation tower is 0.20 cm / s and the dispersed phase velocity is 0.80 cm / s, the gas holdup is 0.05% and the liquid holdup is 0.35%; the process water extractive distillation tower is packed with bulk packing. The high polymer contained in the process water entering the process water extractive distillation tower is 50.0mg / L, and after extraction and rectification separation, the high polymer contained in the process water flowing out of the process water extractive distillation tower is only 0.4mg / L, thus During the 3-5 year normal operation period of the entire ethylene unit, coking did not occur in the convection section of the cracking furnace, and the operation period of the cracking furnace was extended to 90 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com