A high-strength q500gjd quenched and tempered state building structure steel plate and its manufacturing method

A technology of building structure and manufacturing method, applied in the field of Q500GJD quenched and tempered building structural steel plate and its manufacturing field, can solve the problems of complex production process, long rolling period, increased production process, etc., and achieve good comprehensive performance, uniform performance, The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

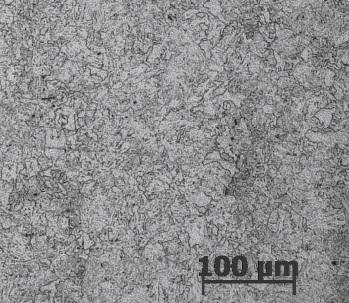

Image

Examples

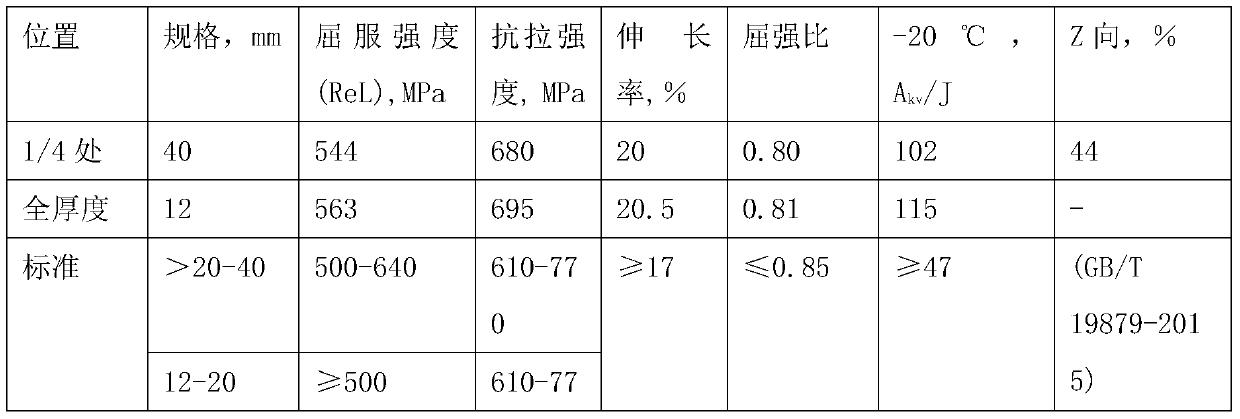

example 1

[0044] Example 1: A 370mm thick continuous casting billet was used to produce a rolled 40mm thick steel plate. The continuous casting slab is 370×2300×3200mm, and the rolled finished plate is 40×2600×L (length) mm. The blank is cold loaded into the heating furnace. The temperature of the preheating section of the heating furnace: 650-700℃, the temperature of the heating section: 1000-1050℃, the temperature of the second heating section: 1150-1200℃, the temperature of the soaking section: 1180-1220℃; Total time 220 minutes. After rough rolling, the thickness of the waiting temperature is 88mm; after warming, the starting temperature of the finishing mill is 820°C, rolling through the finishing mill, and the final rolling temperature is 810°C; it is leveled by a hot straightening machine; Roll off the production line at 335°C for slow cooling; after 37 hours of slow cooling, the appearance quality inspection of the steel plate is carried out; qualified plates are transferred to...

example 2

[0045] Example 2: Design and use 150mm thick continuous casting billet to produce and roll 20mm thick steel plate. The continuous casting slab used is 150×2400×3500 mm, and the rolled finished plate is 12×2800×L (length) mm. The billet is cold-loaded into the heating furnace, and the heating process is the same as the example 1. After rough rolling to a thickness of 65mm, it is sent to a finishing mill for rolling, and the final rolling temperature is 795°C; after rolling, the rolled piece is directly sent to a hot straightening machine for leveling; it is sent to a cooling bed for natural cooling; then finishing, steel plate appearance quality inspection; Qualified boards are transferred to the heat treatment process. Quenching temperature is 905°C, time in furnace is 25 minutes, water cooling; tempering temperature is 660°C, time in furnace is 27 minutes, air cooling to room temperature. Flaw detection, appearance quality inspection and sampling, physical and chemical insp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com