Japanese standard SD345 ribbed twisted steel bar and production method thereof

A threaded steel bar and production method technology, applied in the field of metallurgy, can solve the problems that the shape of "bamboo ribs" is difficult to meet the standard requirements, the shape design of "bamboo ribs" is unreasonable, and the strengthening and utilization are not sufficient, so as to achieve good economic and social benefits. Benefits, low cost, and the effect of reducing the precipitation temperature and brittle transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

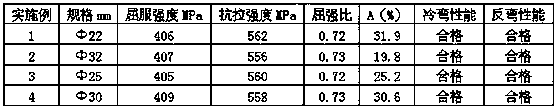

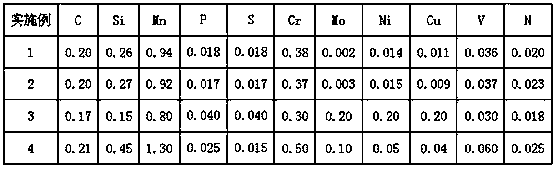

[0021] The specification of the daily standard SD345 steel bar in this embodiment is Φ22mm, and its chemical composition and mass percentage are shown in Table 1.

[0022] The production method of the daily standard SD345 steel bar of the present embodiment comprises steel billet heating, rolling and cooling process, and concrete process step is as follows:

[0023] (1) Heating process: the chemical composition and mass percentage of the steel billet are shown in Table 1, the soaking section temperature is 1105°C, the holding time is 52min; the furnace temperature is 1066°C;

[0024] (2) Rolling process: the steel billet is rolled after being descaled by high-pressure water, the rough rolling start temperature is 1031°C; the final rolling temperature is 1062°C;

[0025] (3) Cooling process: Light water cooling process is adopted, and the temperature of the cooling bed after cooling is 950°C.

[0026] The mechanical properties of the hot-rolled steel bars are shown in Table 2....

Embodiment 2

[0028] The specification of the daily standard SD345 steel bar in this embodiment is Φ32mm, and its chemical composition and mass percentage are shown in Table 1.

[0029] The production method of the daily standard SD345 steel bar of the present embodiment comprises steel billet heating, rolling and cooling process, and concrete process step is as follows:

[0030] (1) Heating process: the chemical composition and mass percentage of the billet are shown in Table 1, the temperature of the soaking section is 1095°C, the holding time is 54min; the temperature of the furnace is 1055°C;

[0031] (2) Rolling process: the steel billet is rolled after being descaled by high-pressure water, the rough rolling start temperature is 1030°C; the final rolling temperature is 1058°C;

[0032] (3) Cooling process: adopt the light-through water cooling process, and the temperature of the cooling bed after cooling is 945°C.

[0033] The mechanical properties of the hot-rolled steel bars are sh...

Embodiment 3

[0035] The specification of the daily standard SD345 steel bar in this example is Φ25mm, and its chemical composition and mass percentage are shown in Table 1.

[0036] The production method of the daily standard SD345 steel bar of the present embodiment comprises steel billet heating, rolling and cooling process, and concrete process step is as follows:

[0037] (1) Heating process: the chemical composition and mass percentage of the billet are shown in Table 1, the temperature of the soaking section is 1070°C, the holding time is 25min; the temperature of the furnace is 1030°C;

[0038] (2) Rolling process: the steel billet is rolled after descaling with high-pressure water, the rough rolling start temperature is 1010°C; the final rolling temperature is 970°C;

[0039] (3) Cooling process: Light water cooling process is adopted, and the temperature of the cooling bed after cooling is 1000°C.

[0040] The mechanical properties of the hot-rolled steel bars are shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com