Device for testing thickness of lubricating oil film of internal combustion engine piston ring assembly

A technology of lubricating oil film and testing device, which is applied in the field of power machinery, can solve problems such as difficult temperature compensation and affecting measurement accuracy, and achieve the effects of avoiding loss of light intensity, high sensitivity, and preventing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

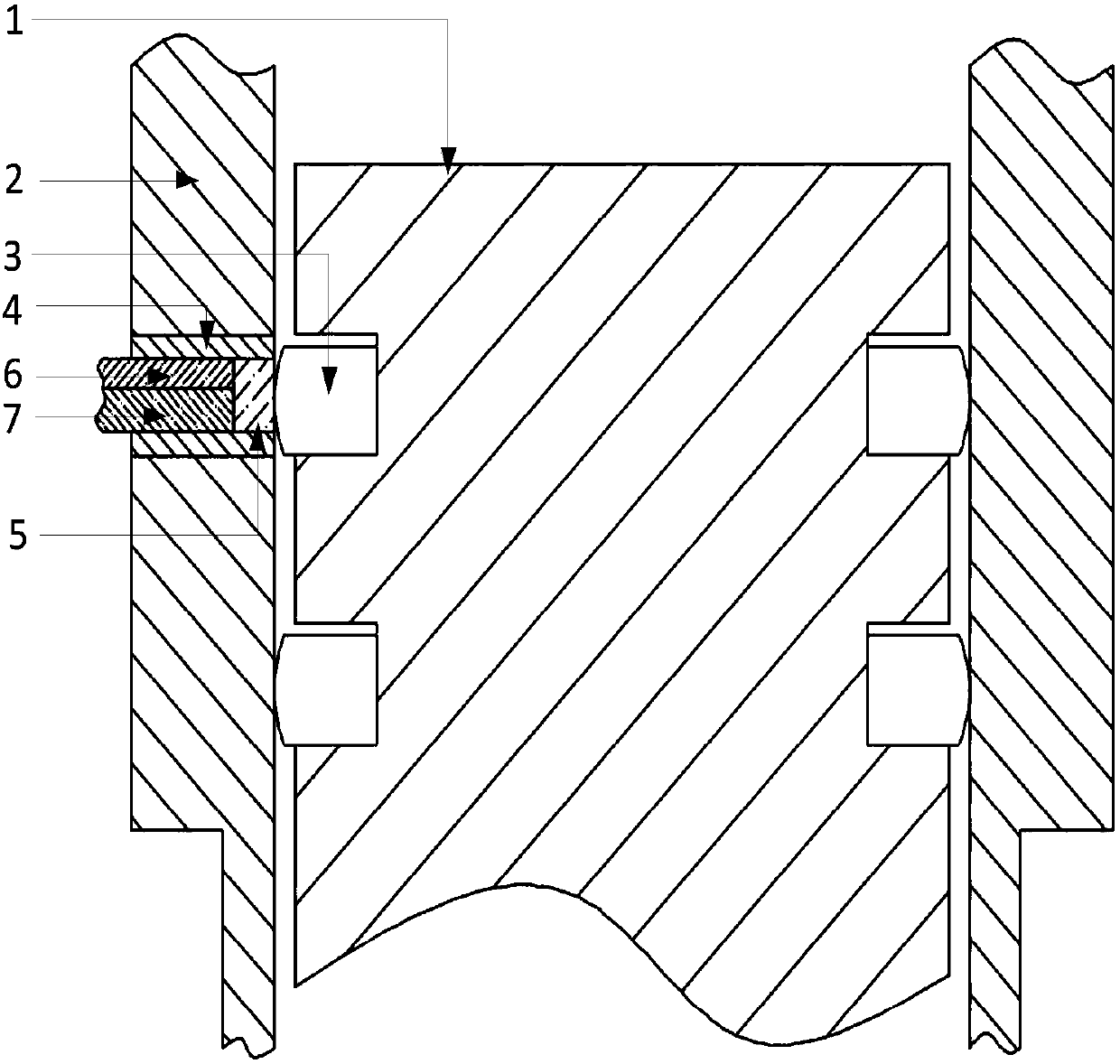

[0027] combine figure 1 and figure 2 , the present invention provides a lubricating oil film thickness testing device for piston ring assemblies of internal combustion engines, comprising: a signal generating module, a testing module, a signal receiving module and a data processing module;

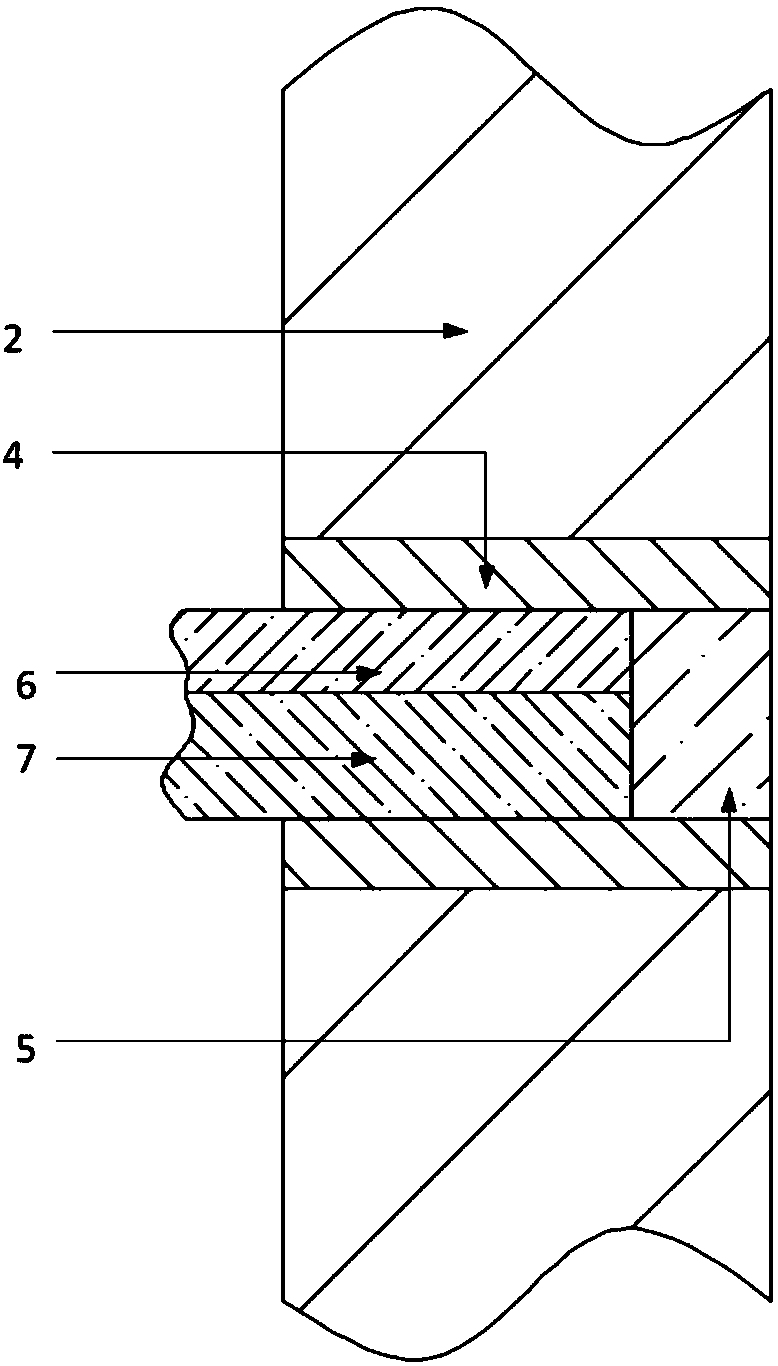

[0028] The test module comprises a shading ring 4, a quartz plate 5, an outgoing optical fiber outlet port 6 and an incident optical fiber collection end 7; the test module is installed in the hole of the cylinder liner 2 of the piston 1, perpendicular to the inner wall of the cylinder liner 2; the quartz plate 5 is installed in the shading ring 4 near the inner wall of the cylinder liner 2. The size of the quartz plate 5 matches the internal size of the shading ring 4. The outer surface of the quartz plate 5 is coplanar with the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com