Solar liquid heat temperature difference power generation device

A technology of thermoelectric power generation and solar energy, applied in the field of new solar liquid thermal thermoelectric power generation devices, can solve the problems of not fully utilizing solar energy, not suitable for household use, wasting energy, etc., achieving a good degree of automation, reducing energy loss and extending service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

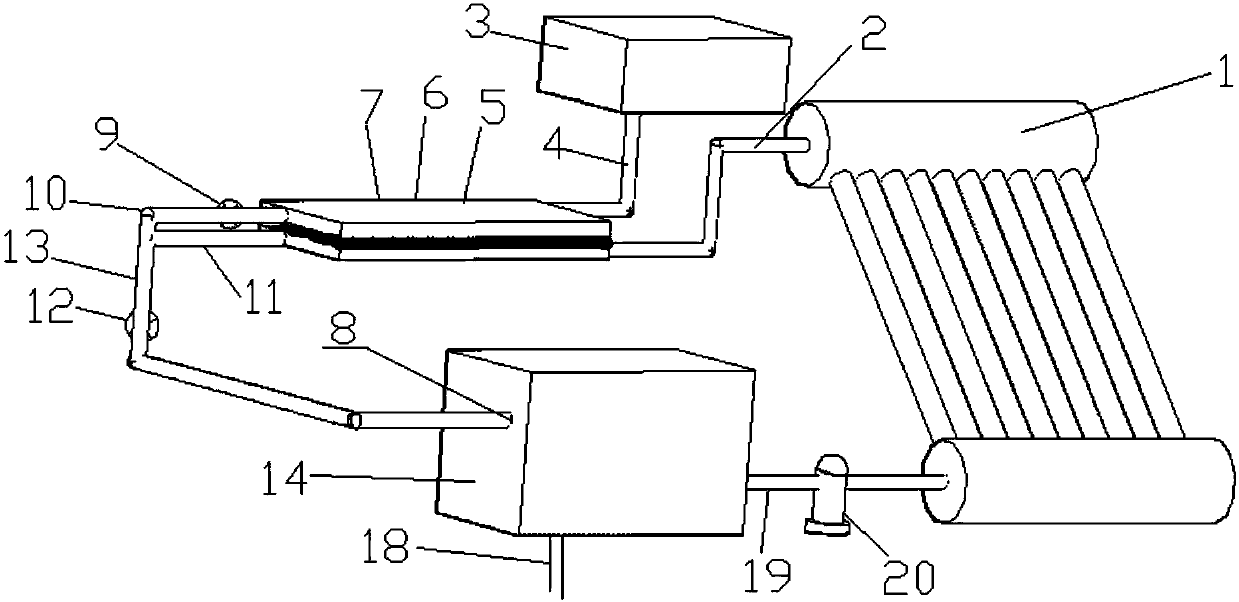

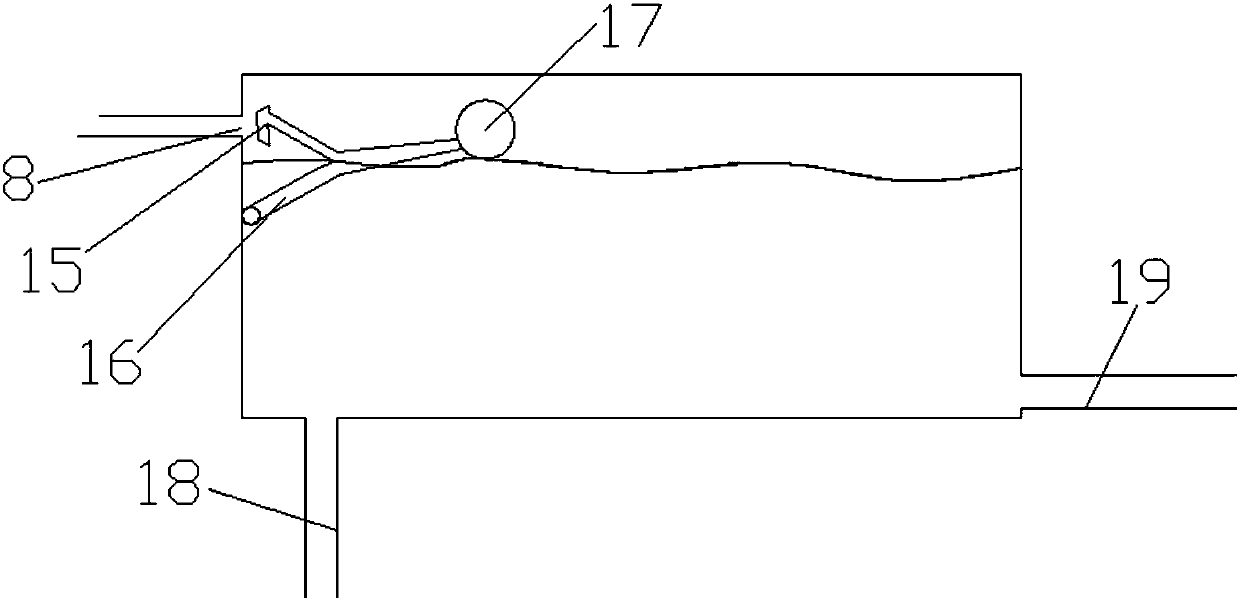

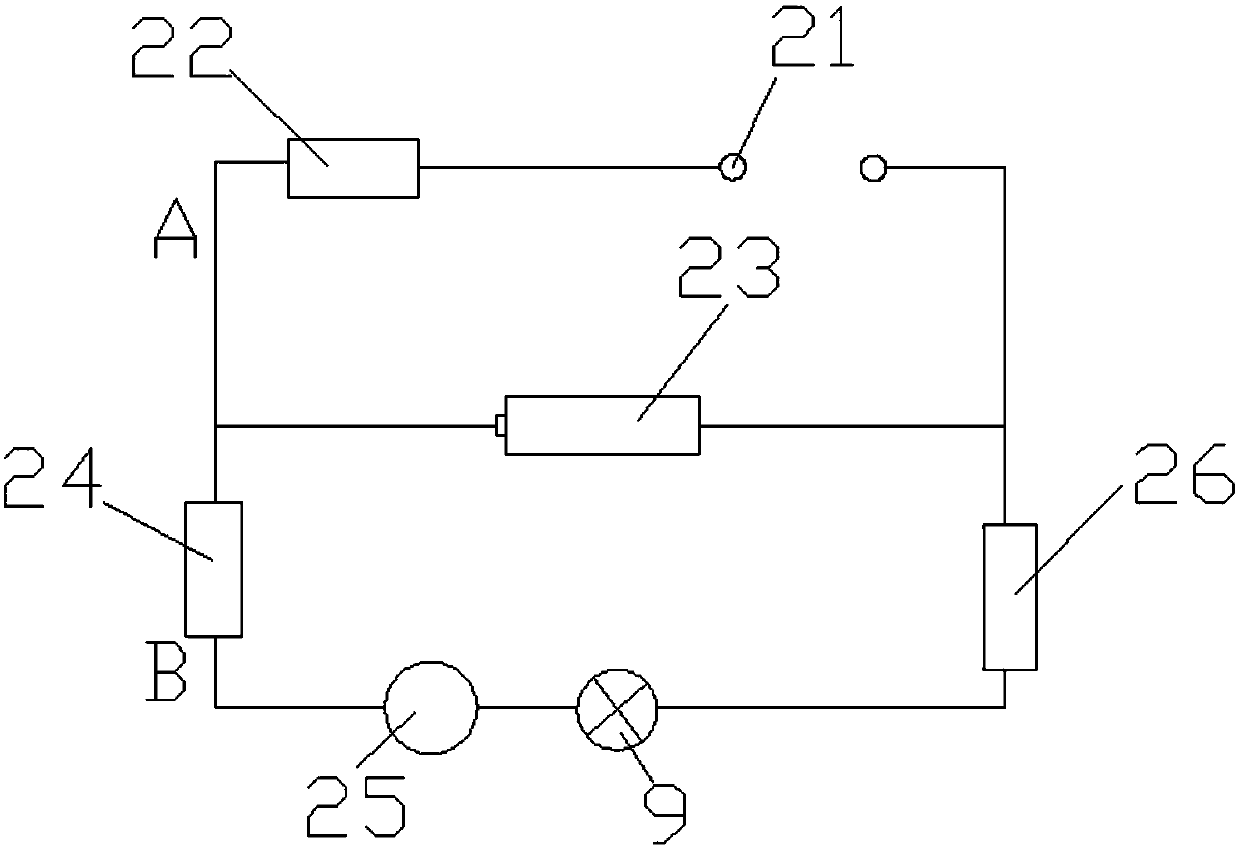

[0030] figure 1 Shown is an embodiment of the solar liquid heat thermoelectric power generation device of the present invention. The solar liquid heat thermoelectric power generation device includes a solar hot water storage tank 1, a hot water pipe 2, a tap water tank 3, a cold water pipe 4, a cold water End 5, thermoelectric power generation element 6, hot end 7, solenoid valve 9, cold end water outlet pipe 10, hot end water outlet pipe 11, constant pressure check valve 12, temperature storage tank inlet pipe 13, temperature storage tank 14, buoyancy plug and Control circuit.

[0031] The tap water tank 3 is arranged at the highest point of the device; the bottom of the tap water tank 3 communicates with the cold end 5 through the cold water pipe 4; the solar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com