Manufacturing method for multilayer structure for image display device

A technology of an image display device and a manufacturing method, which are applied in the directions of identification devices, films/sheets without carriers, and film/sheet adhesives, etc., can solve problems such as difficulty, and achieve the effect of reliable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

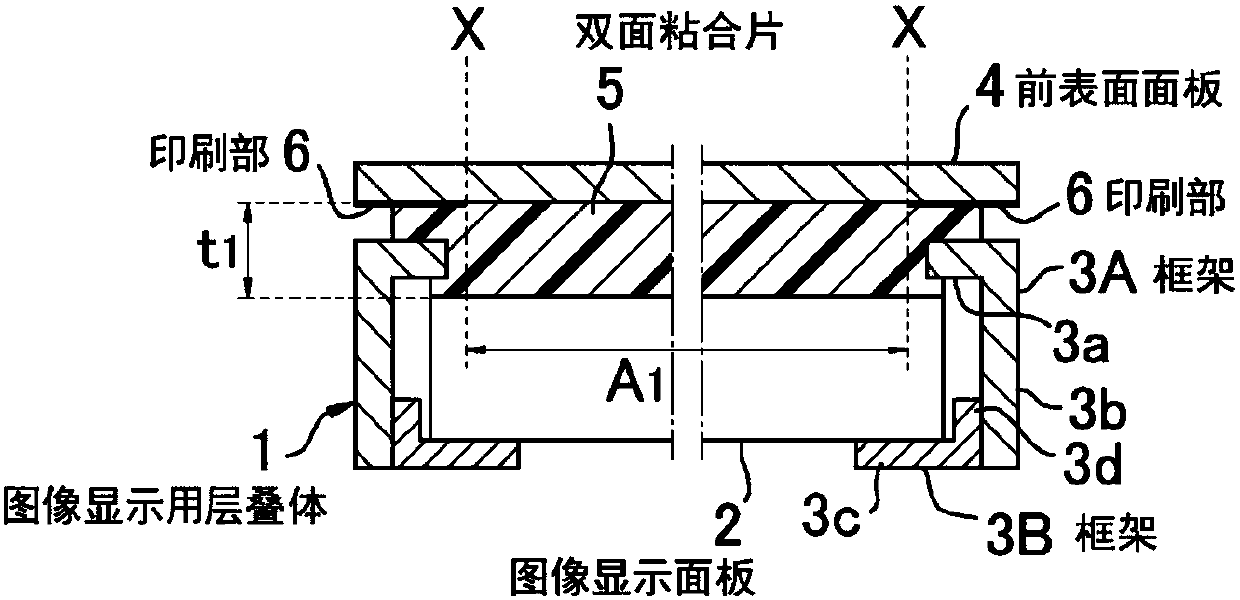

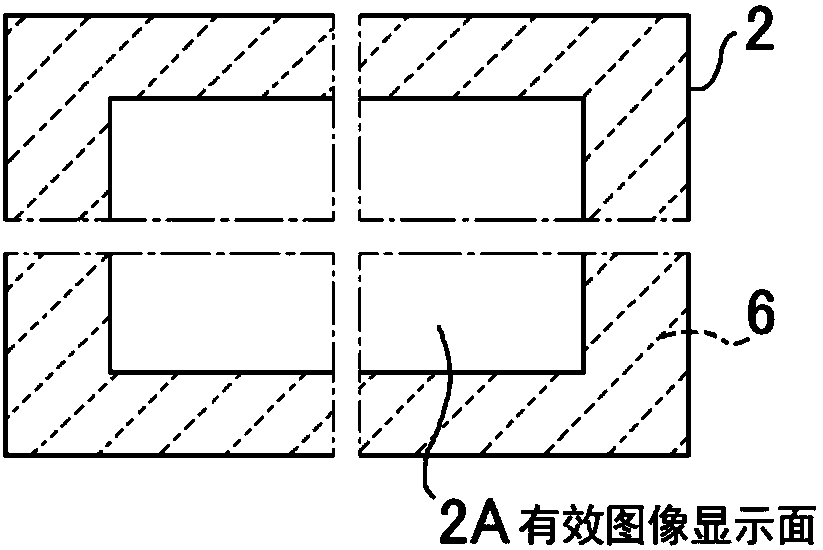

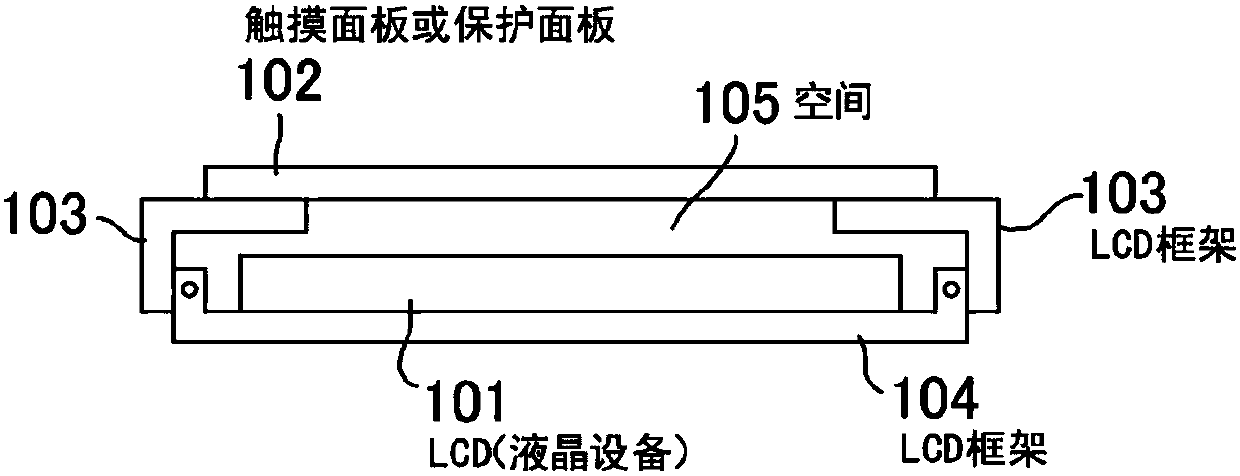

[0225] In the present example, after preparing the adhesive composition, a double-sided adhesive sheet was prepared so as to satisfy [Formula 1], and then, the front edge of the frame was sandwiched between the image display panel and the front panel. Between, and sandwiching the double-sided adhesive sheet, the aforementioned image display panel and the aforementioned front panel are stacked to form a laminated body, and then the aforementioned laminated body is heated to soften the aforementioned double-sided adhesive sheet, and then, by irradiating The active energy ray crosslinks the double-sided pressure-sensitive adhesive sheet to bond the image display panel and the front panel, thereby producing a laminate for an image display device.

[0226] The description will be given in order below.

[0227] (synthesis of macromers)

[0228] Add 900 parts by mass of deionized water, 60 parts by mass of 2-sulfoethyl sodium methacrylate, 10 parts by mass of potassium methacrylate ...

Embodiment 2

[0251] The laminated body 1 for image display apparatuses was produced similarly to Example 1 except having made the dimension of the double-sided adhesive sheet α into 293 mm x 180 mm, and thickness 0.5 mm.

Embodiment 3

[0253] Prepare 50 parts by weight of 2-ethylhexyl acrylate (homopolymer Tg (glass transition point of polymer obtained by polymerizing only 2-ethylhexyl acrylate): -70°C), 45 parts by weight of vinyl acetate Acrylate copolymer (A-2) (Mn=65400, Mw=167000, Mw / Mn=2.56). 70 g of UV-curable resin propoxylated pentaerythritol triacrylate ("ATM-4PL" manufactured by Shin-Nakamura Industry Co., Ltd.) 15 g of 4-methylbenzophenone to prepare adhesive composition b.

[0254] Instead of the PSA composition a used in Example 1, the above-mentioned PSA composition b was used to produce a double-sided PSA sheet β.

[0255] It was confirmed that the double-sided PSA sheet β has a glass transition temperature (Tg) of 10°C, softens when heated to 60-100°C, and is irradiated with a high-pressure mercury lamp with a cumulative light intensity of 2000mJ / cm on one side. 2 When cross-linking with ultraviolet energy (converted to a wavelength of 365 mm), the holding force measured in the holding f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com