Attraction device, method for producing attraction device, and vacuum processing device

A technology of vacuum processing device and adsorption device, which is applied to holding devices, manufacturing tools, positioning devices, etc. using electrostatic attraction, can solve the problems of reduced substrate yield and wrong substrate transportation, and achieves extended life, dust prevention, general-purpose Sexually wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

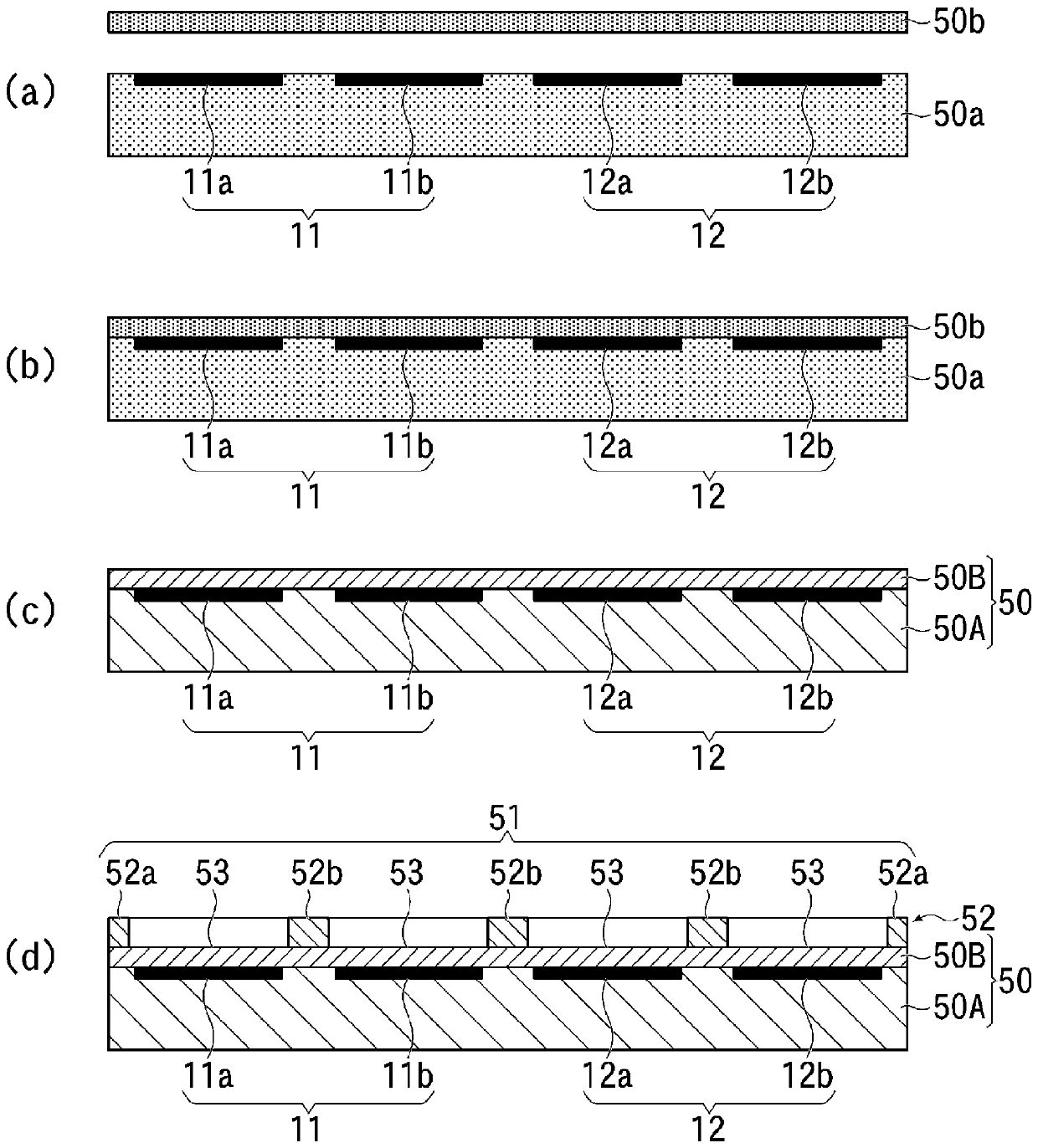

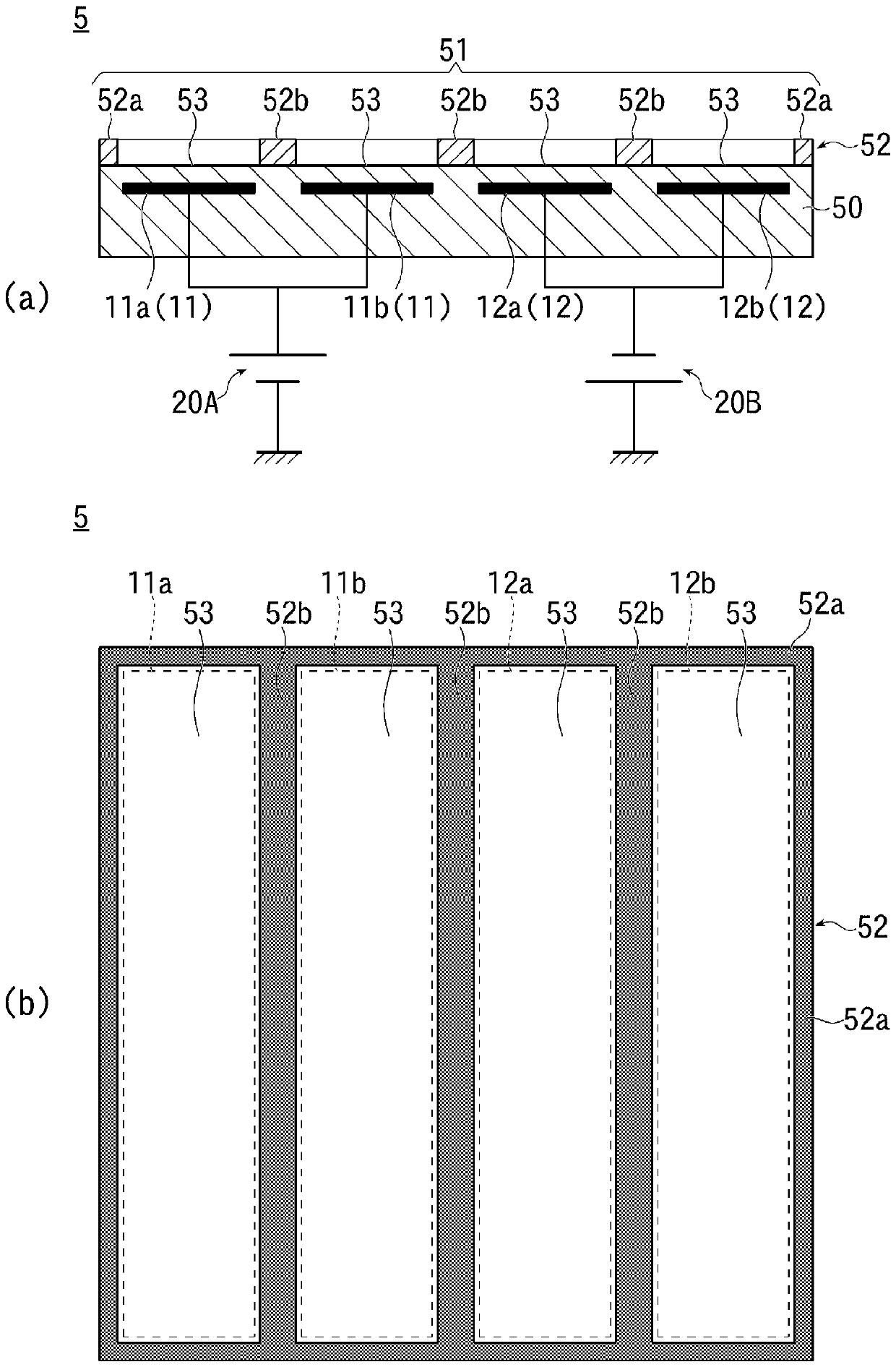

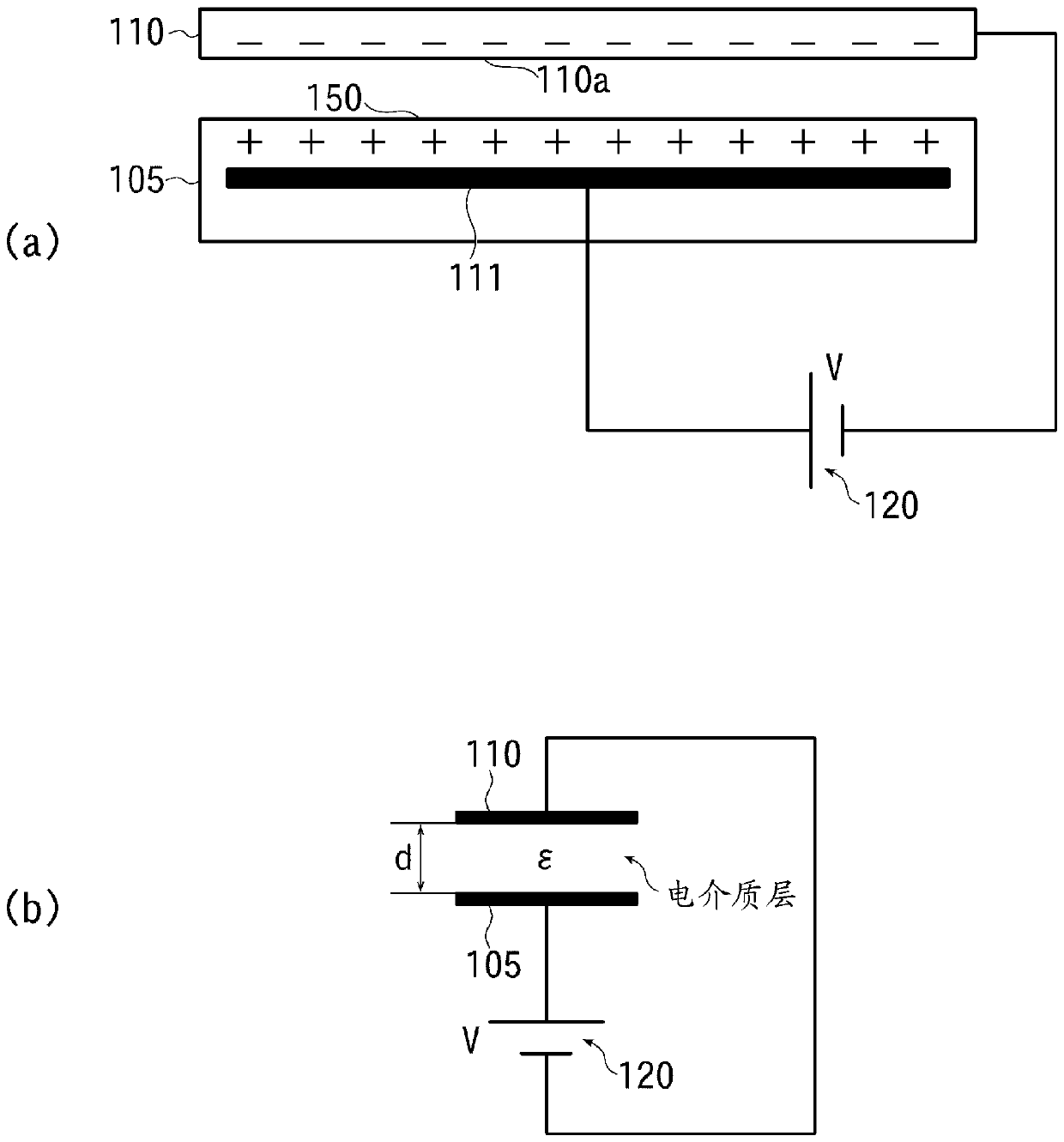

[0038] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0039] In addition, the present invention can be applied to both bipolar and monopolar adsorption devices.

[0040] figure 1 It is a schematic configuration diagram of a sputtering apparatus which is an embodiment of the vacuum processing apparatus of the present invention.

[0041] exist figure 1 In the figure, reference numeral 2 denotes a vacuum chamber of the sputtering apparatus 1 according to the present embodiment, and the vacuum chamber 2 is configured to be connected to a vacuum exhaust system (not shown) to introduce sputtering gas.

[0042] The target 3 as a film formation source is arrange|positioned in the upper part in the vacuum chamber 2. As shown in FIG.

[0043] The target 3 is connected to a sputtering power supply 4, and a negative bias voltage is applied thereto. In addition, the positive side of the sputtering power supply 4 is grounded togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com