Air conditioner outdoor unit assembly and air conditioner

A technology of air conditioners and components, applied in air conditioning systems, space heating and ventilation, space heating and ventilation details, etc., can solve the problems of increased volume and weight, unfavorable electronic control miniaturization, and large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

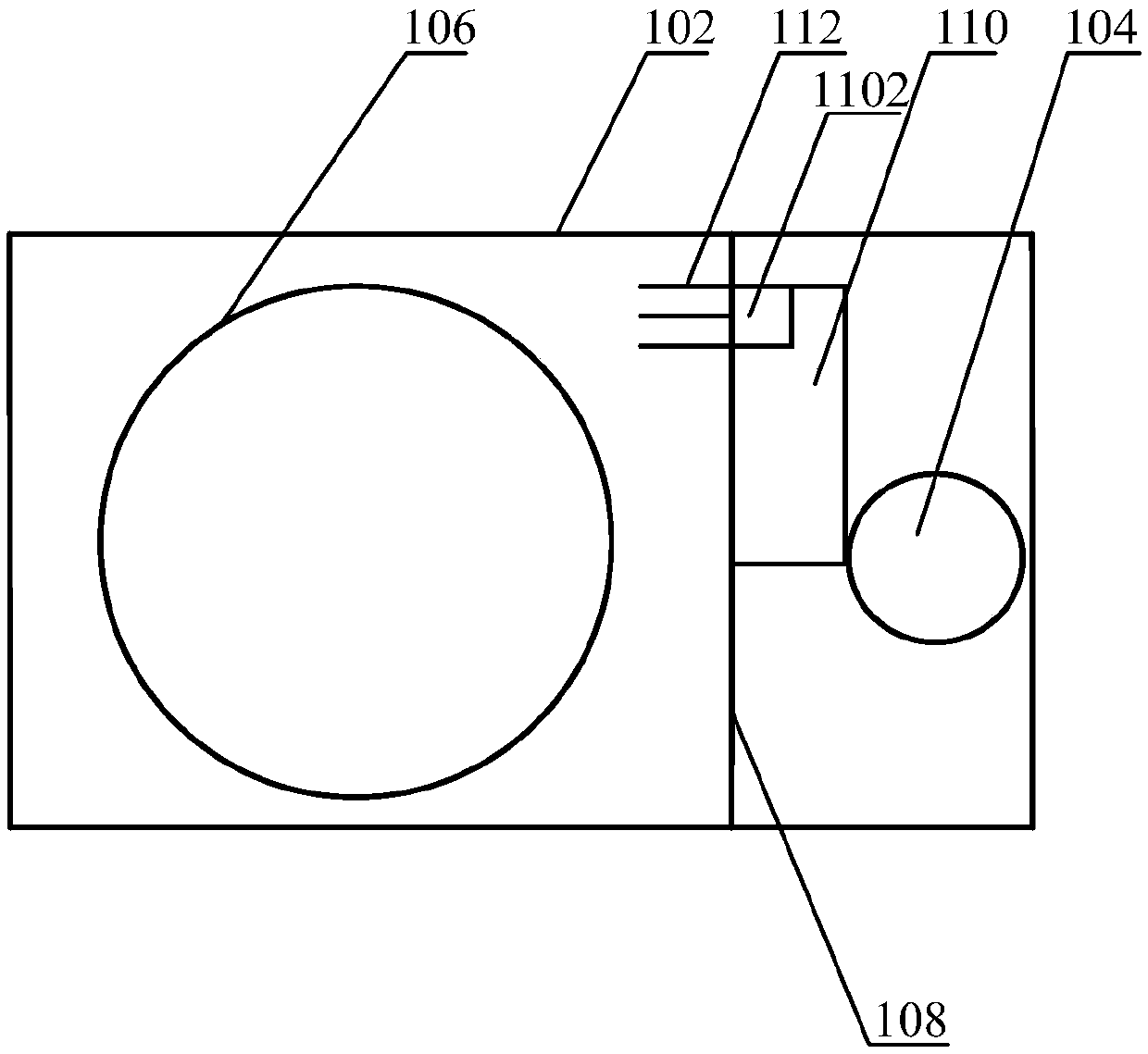

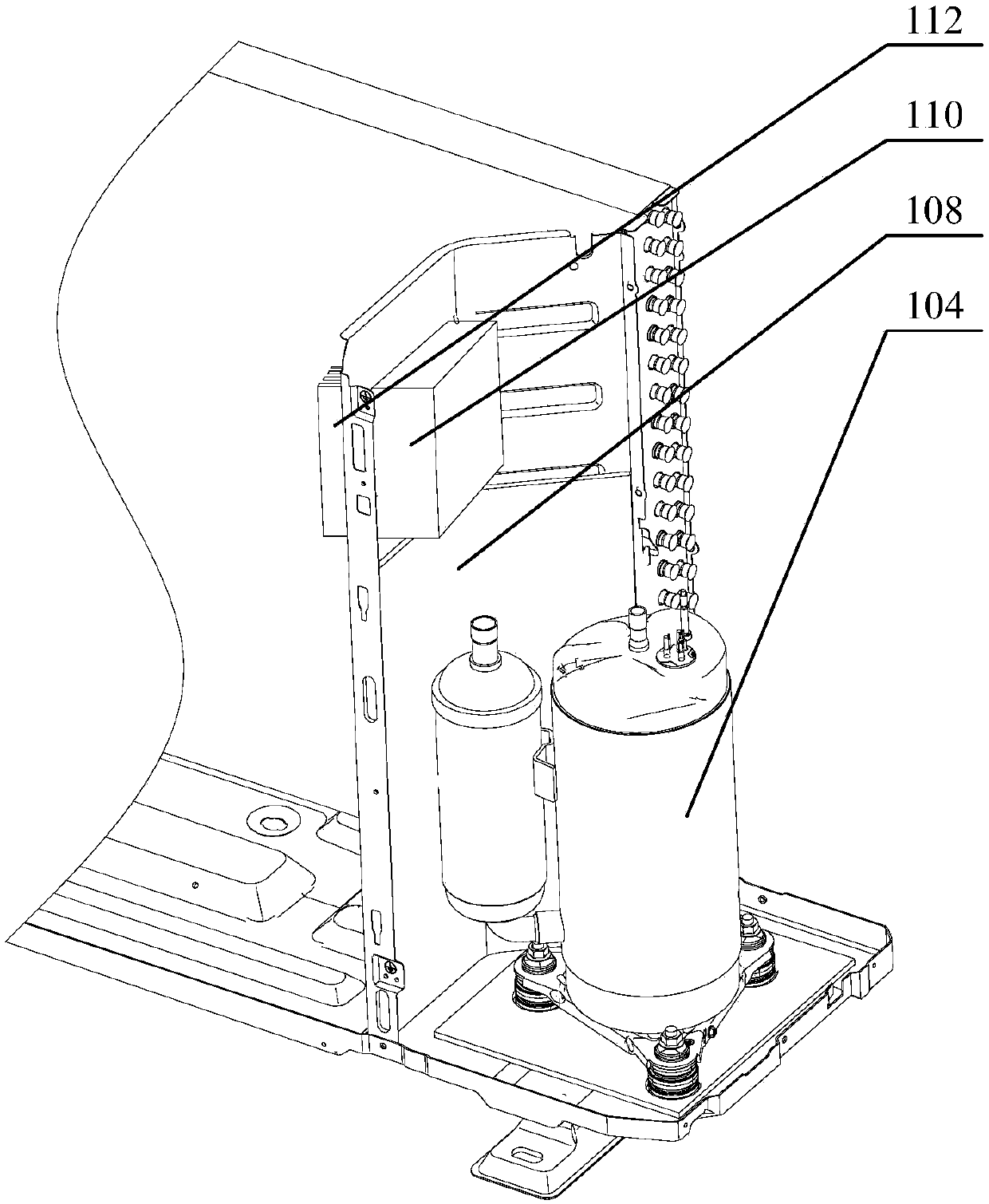

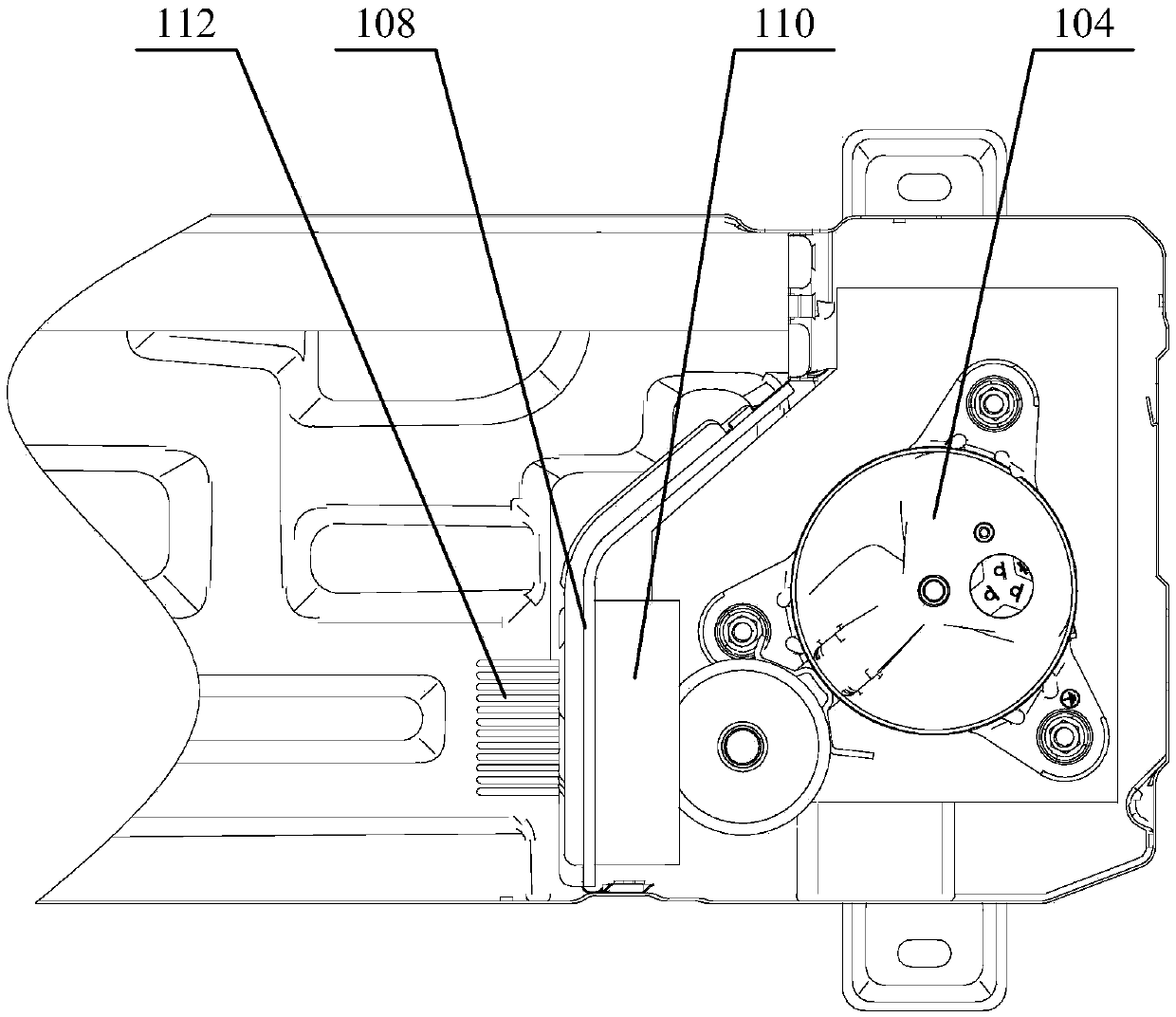

[0047] Such as figure 1 and figure 2 As shown, the air conditioner external unit assembly according to the embodiment of the present invention includes: an electric control assembly 110 installed on the side of the partition plate 108 corresponding to the compressor 104, the electric control assembly 110 includes a power device 1102, and the power device The heat dissipation surface of 1102 is set corresponding to the partition 108 to dissipate heat to the partition 108 .

[0048] In this embodiment, by installing the electric control assembly 110 on the partition 108, and setting the heat dissipation surface of the power device 1102 in the electric control assembly 110 corresponding to the partition 108, when the air conditioner is running, due to the power device 1102 When the temperature of the electronic control component 110 rises due to heat generation, the heat is dissipated through the heat dissipation surface to transfer the heat of the power device 1102 to the part...

Embodiment 2

[0053] Such as figure 1 As shown, in the above embodiment, preferably, it also includes: a heat dissipation device, which is arranged on the side of the partition plate 108 corresponding to the outdoor fan 106, and is arranged in the air duct area of the outdoor fan 106, and the heat dissipation device and the power device 1102 is correspondingly arranged on both sides of the partition 108 , wherein the heat generated by the power device 1102 is transferred to the partition 108 , and then transferred to the cooling device by the partition 108 to form a cooling airflow through the operation of the outdoor fan 106 .

[0054] In this embodiment, by setting the electric control assembly 110 separately from the heat dissipation device and installing them on both sides of the partition 108 respectively, and setting the heat dissipation device corresponding to the power device 1102 in the electric control assembly 110, the power device 1102 When generating heat during operation, th...

Embodiment 3

[0057] In any of the above embodiments, preferably, the power device 1102 respectively includes a rectification unit device, a PFC unit device and an inverter unit device that are electrically connected in sequence, and the rectification unit device, the PFC unit device and the inverter unit device are mounted on at least On one circuit board, at least one circuit board is insulated and mounted on the partition 108 , wherein the rectifier unit device, the PFC unit device and the inverter unit device are arranged opposite to the partition board 108 to transfer heat to the partition board 108 through heat dissipation.

[0058] In this embodiment, for the electric control assembly 110 of the external machine assembly, the power device 1102 mainly includes a rectification unit device, a PFC unit device and an inverter unit device, and the rectification unit device, the PFC unit device and the inverter unit device can be respectively arranged in On three circuit boards, or arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com