Hot air heat exchanger of biomass combustion equipment

A technology of heat exchangers and biomass particles, which is applied in the field of feed devices of biomass combustion equipment, can solve the problems of low heat exchange efficiency, achieve the effects of long heat exchange time, increase heat exchange strokes, and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

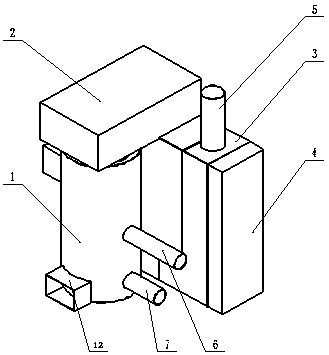

[0023] Such as figure 1 Shown, a kind of biomass particle hot air heat exchanger is characterized in that: comprise combustion chamber 1, flue gas box 3, heat exchange pipeline 13 and air reversing box 4;

[0024] The combustion chamber 1 is provided with a feed port 6, and the smoke box is provided with a smoke exhaust port 5;

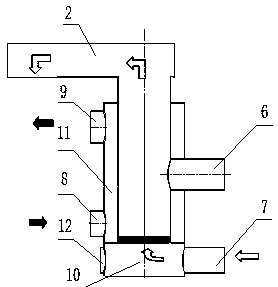

[0025] Such as figure 2 As shown, the hot air chamber 11 surrounds the outer wall of the combustion chamber 1, and the hot air chamber 11 is provided with a hot air inlet 8 and a hot air outlet 9;

[0026] Such as Figure 1~Figure 2 As shown, the combustion chamber 1 is connected to the smoke box 3 through the smoke channel 2 , the combustion chamber 1 is connected to the inlet of the smoke channel 2 , and the outlet of the smoke channel 2 is connected to the smoke inlet of the smoke box 3 .

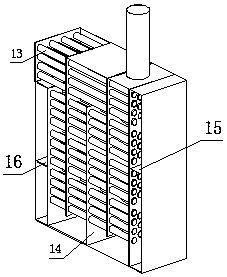

[0027] Such as Figure 3~Figure 4 As shown, the combustion chamber 1 is connected to the flue gas box 3, the flue gas generated by the combustion chamber 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com