Vertical inner-container-free energy-saving environment-friendly boiler

An energy-saving and environmental-friendly boiler technology, applied in steam boilers, water-tube steam boilers, steam generation, etc., can solve problems such as increased steam production costs, reduced pressure bearing capacity, and poor safety performance, achieving major social and economic benefits and reducing production Manufacturing cost, effect of enhancing heat absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

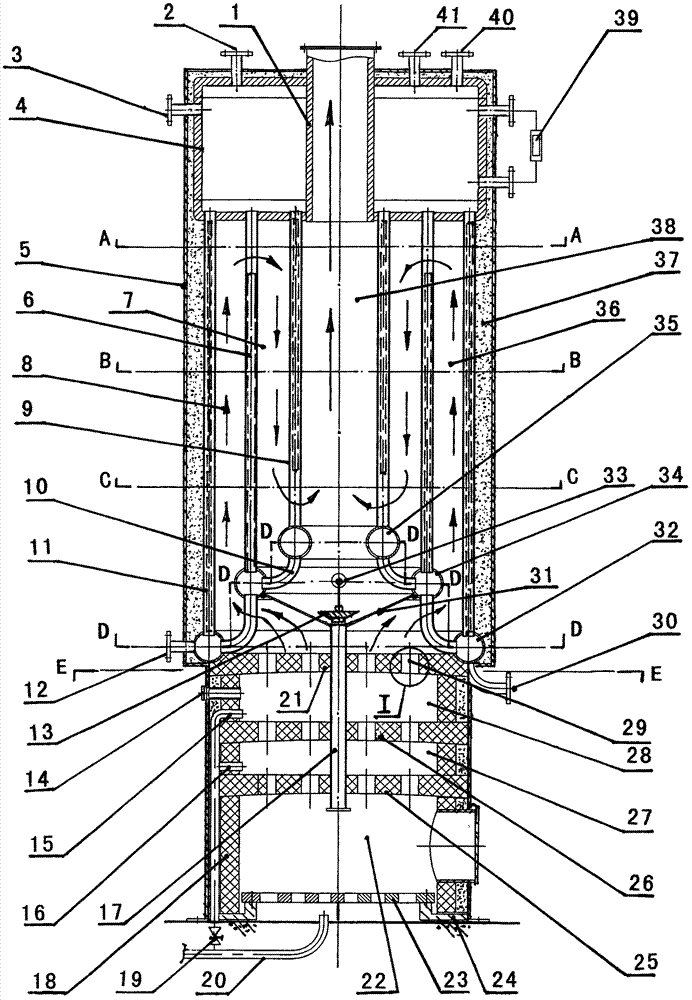

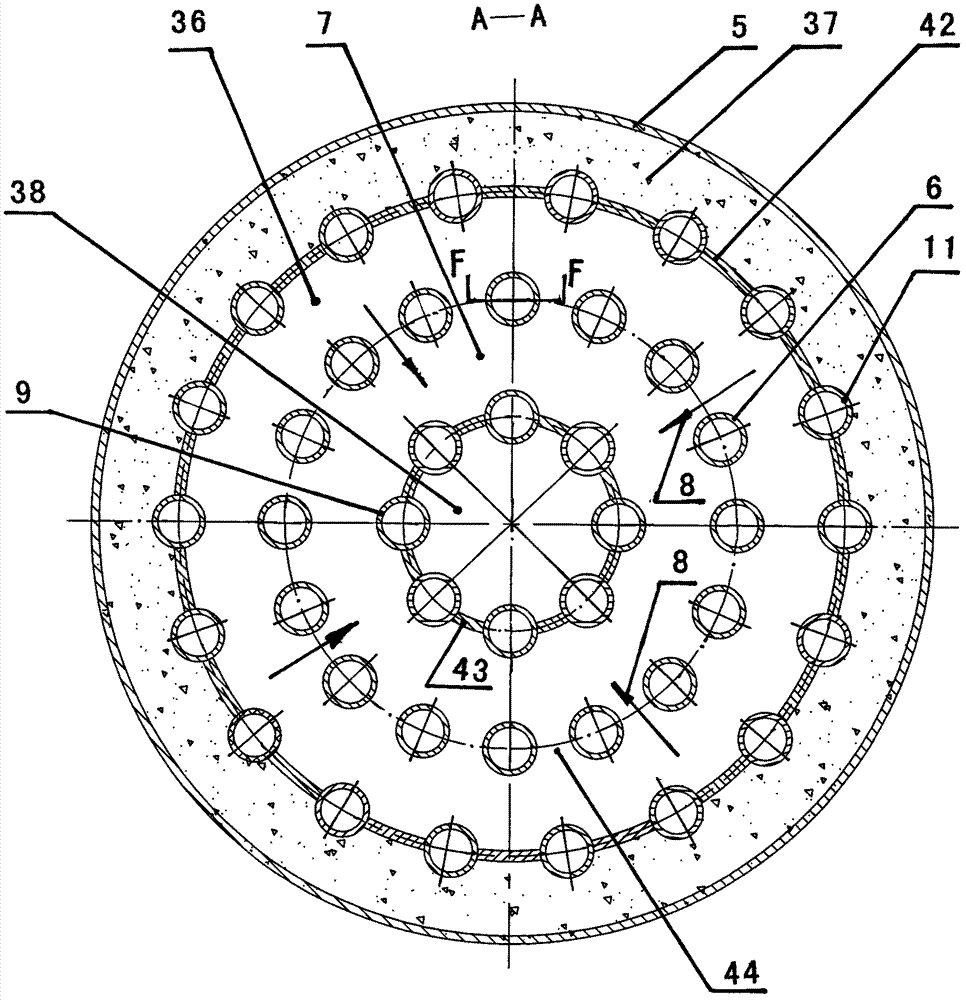

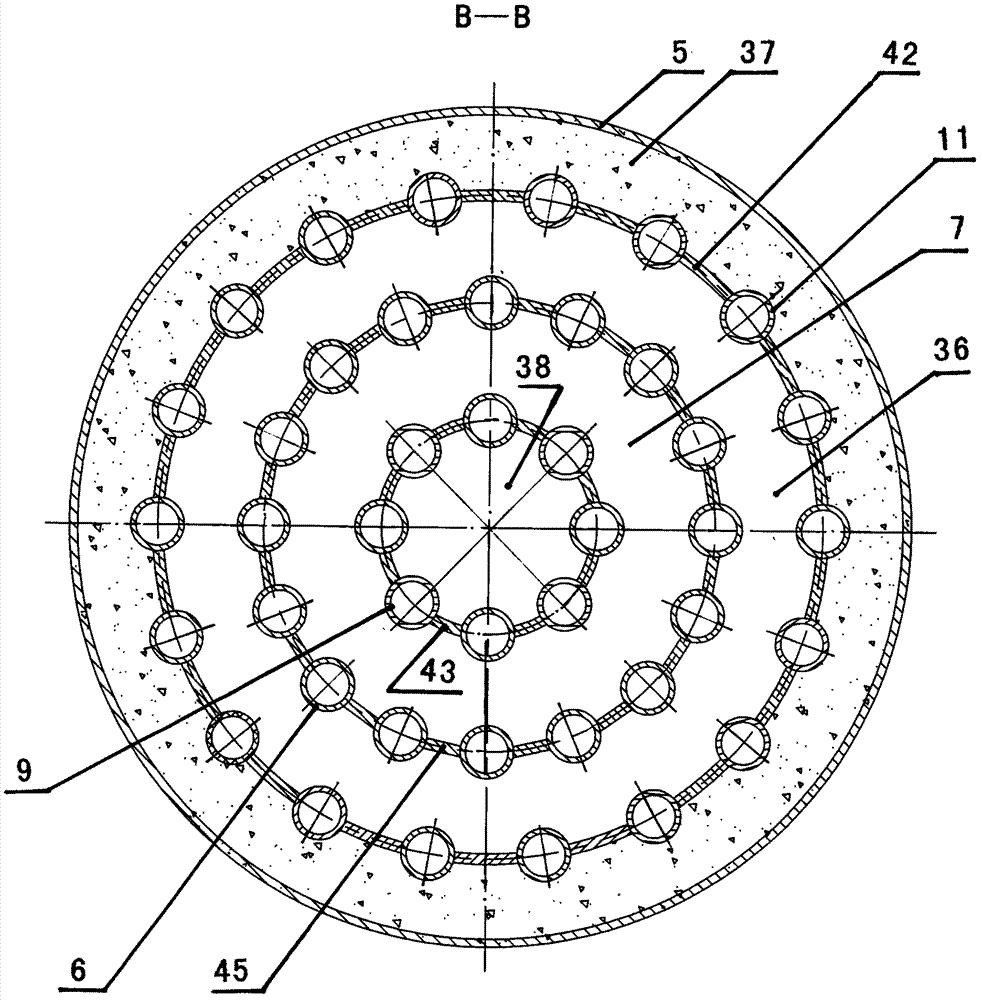

[0038] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0039] The vertical gallbladderless energy-saving and environment-friendly boiler proposed by the present invention is mainly composed of a furnace shell 5, a combustion chamber 18 installed on the furnace base 24, an outer annular pipe 32, an outer ring water-cooled pipe 11, a middle annular pipe 34, and a middle annular pipe 34 connected to the middle annular Conical bucket 31 of pipe wall 34, middle ring water cooling pipe 6, inner annular pipe 35, inner ring water cooling pipe 9, steam drum 4 and smoke exhaust pipe 1 are formed, and partition arch 25 is set in the furnace 22 of combustion chamber 18 to be divided into two Secondary combustion hearth 27, in secondary combustion hearth 27, secondary partition arch 26 is set to be divided into tertiary combustion hearth 28, and secondary combustion hearth 27, tertiary combustion hearth 28 are respectively eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com