Heat-absorbing pouring sealant and a battery thereof

A technology for potting glue and battery modules, which is used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve problems such as rising costs, limited promotion of sealing requirements, and increased system complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The preparation method of the heat-absorbing potting glue of the embodiment of the present application can adopt the following methods:

[0077] 1. Mix the raw materials of component A evenly in proportion to prepare component A and package it separately; mix the raw materials of component B uniformly in proportion to prepare component B and package it separately;

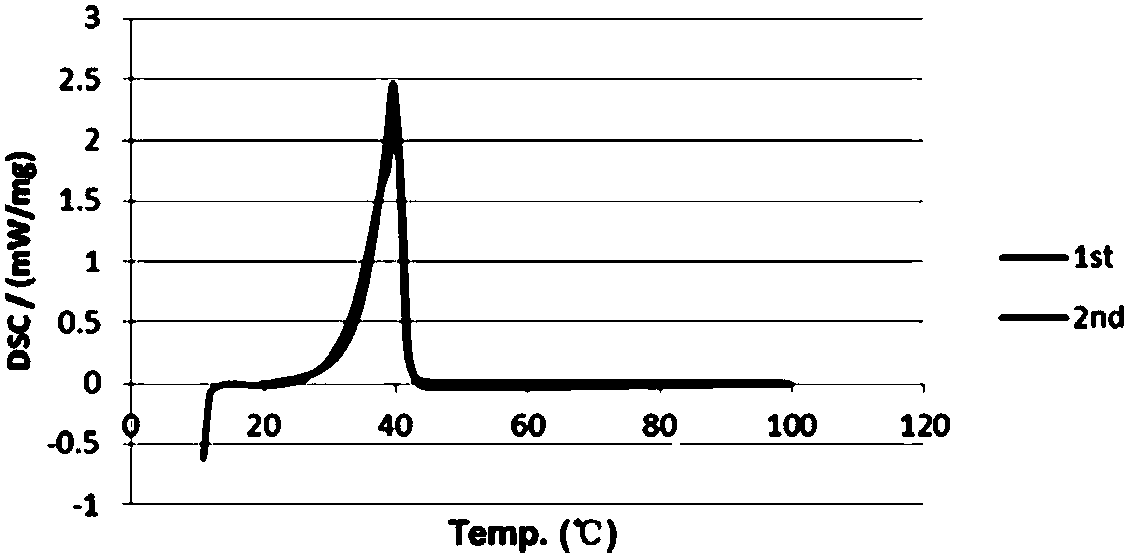

[0078] 2. Mix component A and component B evenly at a weight ratio of 1:1, and cure at 40°C to 50°C for 15 to 45 minutes to form an endothermic potting glue.

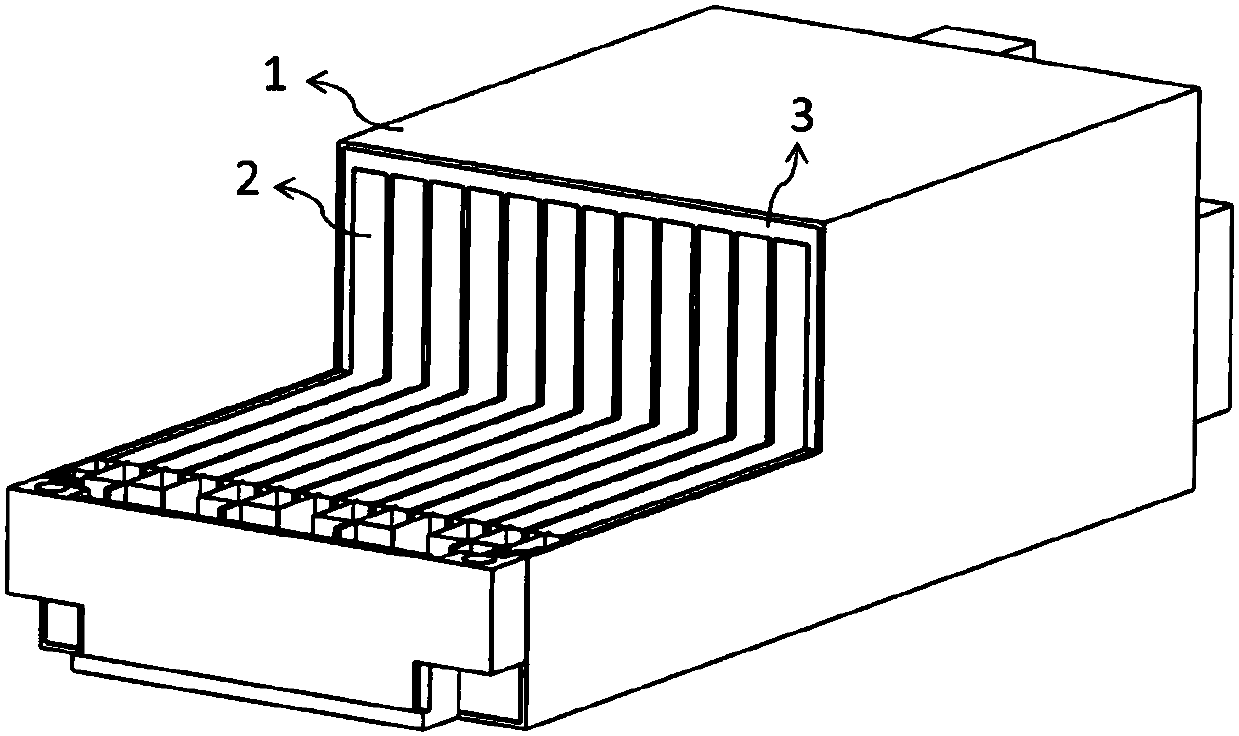

[0079] In the embodiment of the present application, a two-component cross-linking and curing method is used to prepare the heat-absorbing potting glue, in which component A and component B are mixed evenly and have considerable fluidity to ensure that all gaps inside the power battery module are filled. After the two-component adhesive is cross-linked and cured, it forms a gel-like soft material to increase the contact between the material and the ba...

Embodiment

[0083] Preparation of heat-absorbing potting compound:

[0084] The preparation method of the endothermic potting glue of the embodiment of the present application is:

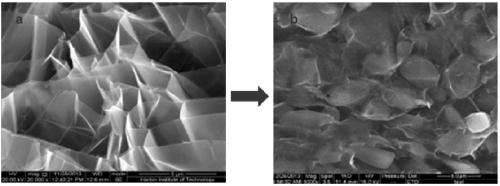

[0085] 1. Mix the raw materials of component A evenly in proportion to prepare component A and package it separately; mix the raw materials of component B uniformly in proportion to prepare component B and package it separately; among them, the endothermic potting Glue 1 # The heat-absorbing powder in it is a composite phase change material of paraffin wax and expanded graphite; the heat-absorbing potting glue 2 # The heat-absorbing powder in it is a composite phase change material of paraffin wax and carbon fiber; the heat-absorbing potting glue 3 # ~Heat-absorbing potting glue 5 # The heat-absorbing powder adopts the phase-change microcapsule whose capsule core is paraffin wax; the heat-absorbing potting glue 3 # The material of the shell of the medium phase change microcapsule is polystyrene, heat-absor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com