Energy saving boiler

A boiler and auxiliary furnace technology, applied in the field of heating equipment, can solve problems such as black smoke, no heat preservation measures, and rapid heat release, etc., to prolong the heat exchange stroke and time, reduce harmful smoke emissions, and increase heat exchange area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

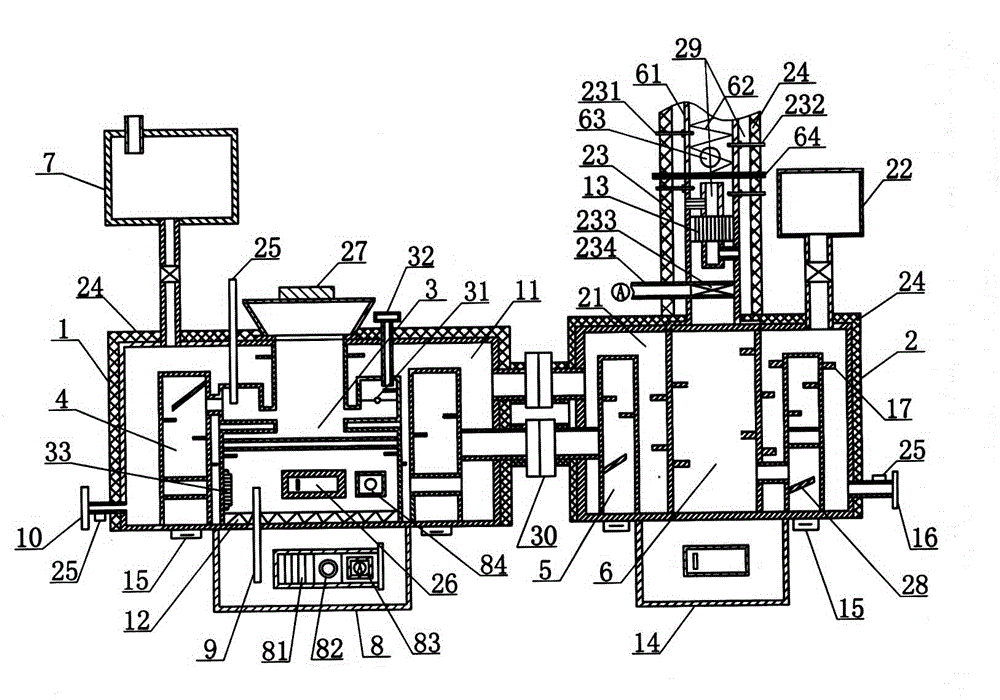

[0027] Such as figure 1As shown, the structure diagram of the energy-saving boiler of the present invention includes a main furnace 1 and an auxiliary furnace 2, the main furnace 1 and the auxiliary furnace 2 are water jacket furnaces, and the outer walls of the main furnace 1 and the auxiliary furnace 2 are coated with an insulating layer 24, Reduce the heat dissipation of the main furnace water jacket 11 and the auxiliary furnace water jacket 21, and further improve heat utilization. The main furnace water jacket 11 and the auxiliary furnace water jacket 21 are connected by a flange 30. The combustion chamber 4 and the secondary combustion chamber 4 are arranged outside the combustion chamber 3 and communicated with the combustion chamber 3. The secondary furnace 2 is provided with a tertiary combustion chamber 5 and a quaternary combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com