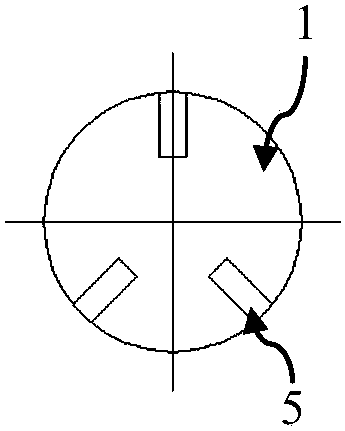

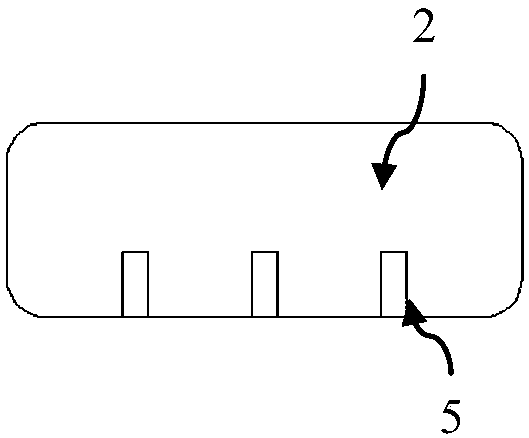

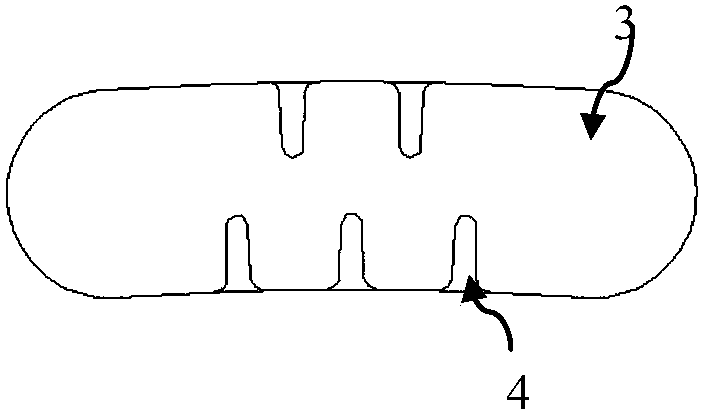

Motor with cooling duct

A technology for cooling pipes and pipes, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of unfavorable lightweight design, single cooling pipe, increase the weight of the motor, etc. perturbation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the drawings.

[0039] The design principle of the present invention is based on the Newtonian cooling formula:

[0040] Φ=hAΔT

[0041] In the formula, Φ——loss generated by the motor, the unit is W;

[0042] h——Convection heat transfer surface heat transfer coefficient, the unit is W / m 2 ·K;

[0043] A——The heat exchange area, the unit is m 2 ;

[0044] ΔT——The average temperature difference on the heat exchange surface.

[0045] For the motor, the internal heat flow Φ remains unchanged. To reduce the temperature difference, that is, to reduce the temperature rise of the motor, it is necessary to increase the convective heat transfer coefficient h on the heat exchange surface or increase the heat dissipation area A. The increase of the heat dissipation area will increase the weight of the motor, which is not conducive to the lightweight design and power density of the motor. Therefore, the heat dissipation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com