Frequency-locking ring-based motor control method and device

A technology of motor control and frequency locking loop, applied in the direction of excitation or armature current control, etc., can solve the problem that the zoom motor cannot be used for accurate positioning, and the motor cannot be determined, so as to achieve miniaturization, achieve precise zoom, and ensure smooth work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

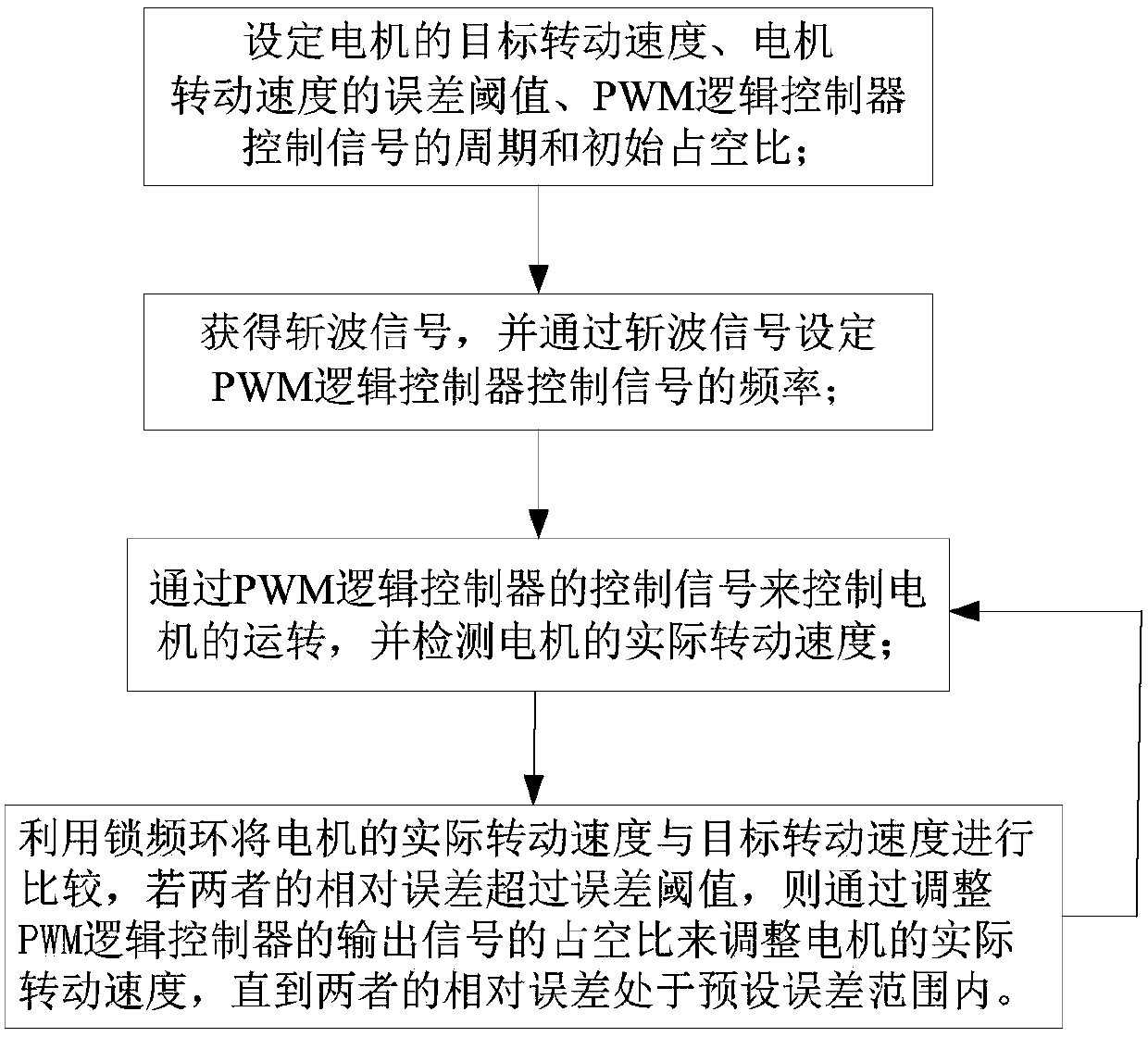

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

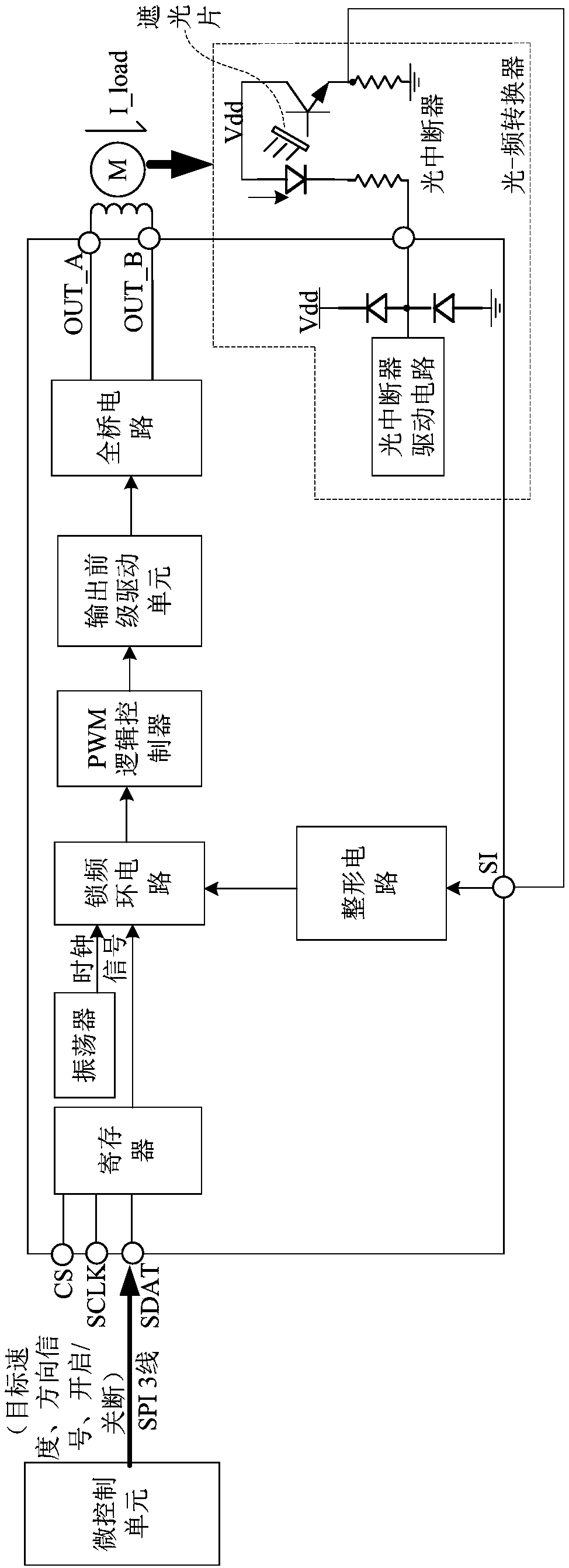

Embodiment Construction

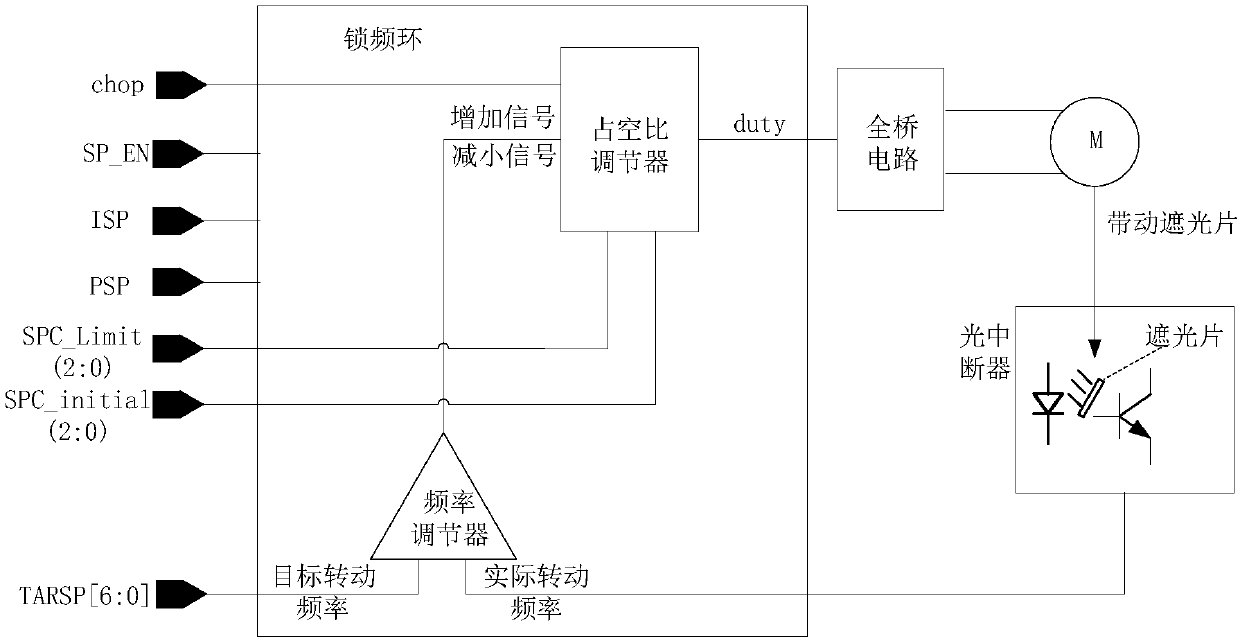

[0036] First of all, the frequency lock loop (FLL, Frequency Lock Loop) is essentially an automatic frequency fine-tuning circuit used dynamically, and it is a typical automatic control loop. The characteristics of an automatic control loop not only depend on the number of loops, that is, the number of poles of the transfer function, but also on the loop type. The so-called "type" here refers to the order of the loop without static error, that is, the number of poles of the transfer function at the origin. In a physical sense, it refers to the number of ideal integrators (transfer function 1 / S) included in the loop. . Most of the frequency-locked loops currently in use are digital frequency-locked loops, and their design generally includes filters, frequency detectors, accumulators, and digital voltage-controlled oscillators. Its transfer function is 1 / S, so a general digital frequency-locked loop can be designed as a first-order loop without static error.

[0037] The present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com