Cleaning and recycling system of blast furnace ore tank area water and using method of cleaning and recycling system

A technology of water cleaning and mine tank, which is applied in the field of blast furnace mine tank dust removal, can solve the problems of dust generation, environmental water pollution, and difficult cleaning of mineral dust particles, and achieve the effects of avoiding blockage, reducing energy consumption, and reducing water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

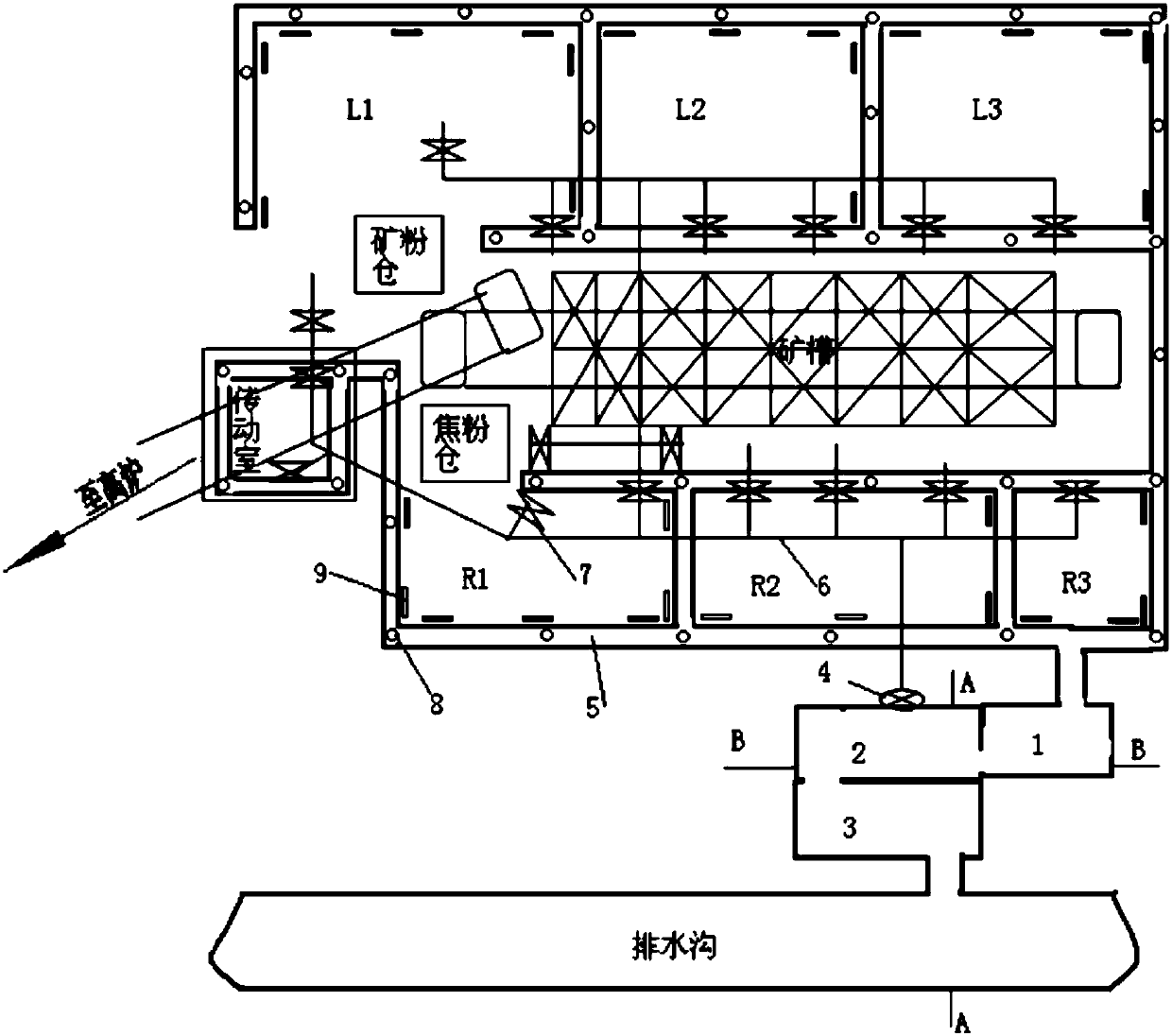

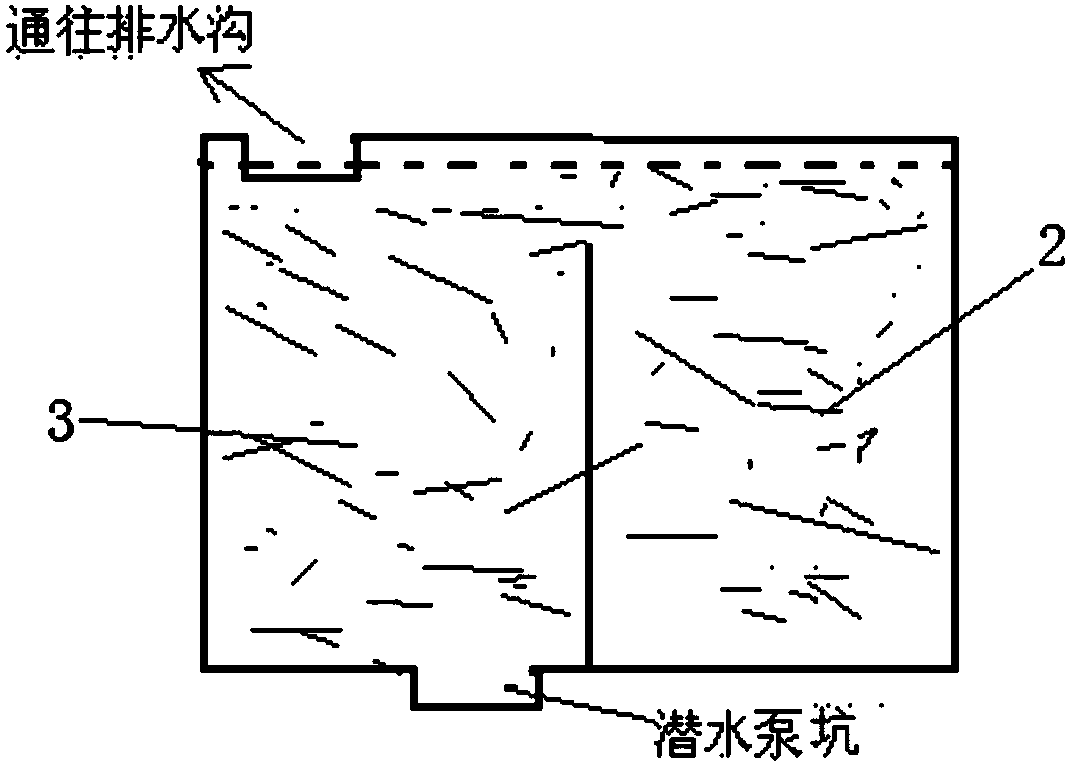

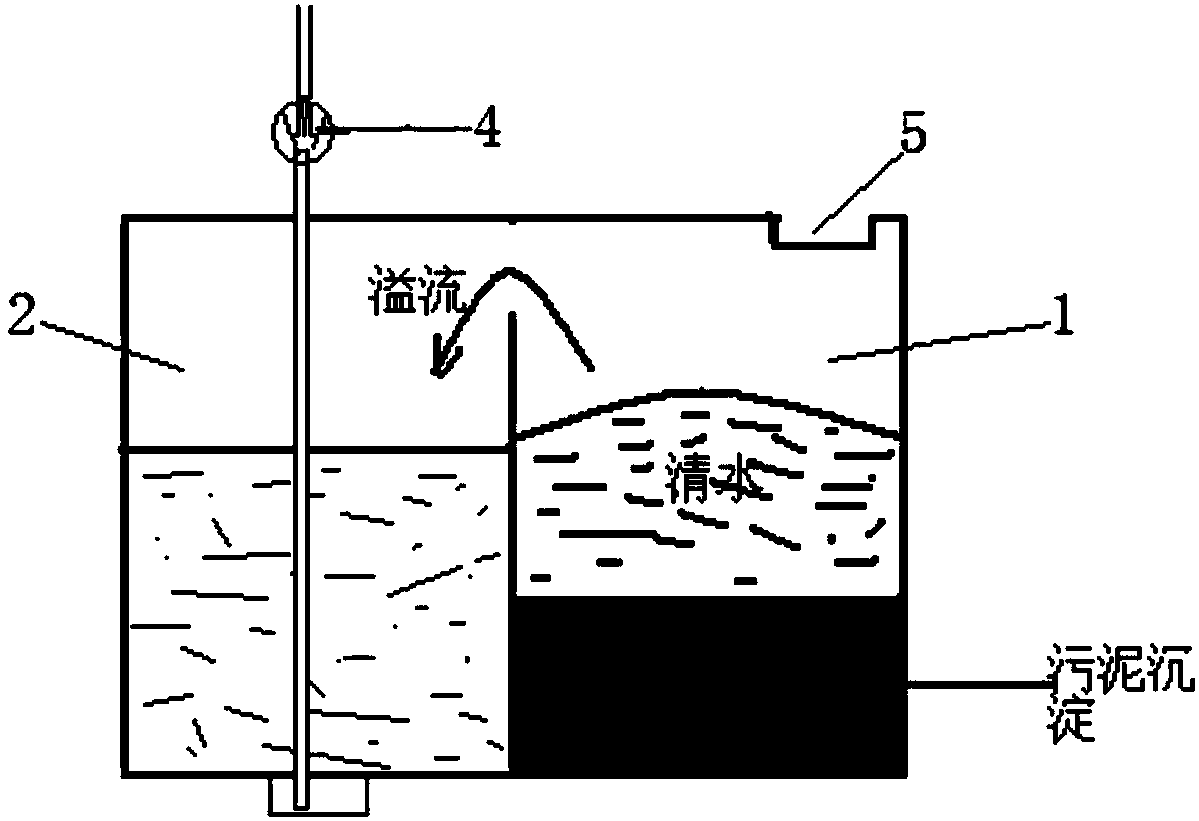

[0039] Such as figure 1 , figure 2 , image 3 As shown, the water cleaning and recycling system of a blast furnace pit area in this embodiment mainly includes a sewage pool 1, a clean water pool 2, a water collection pool 3, a drainage pump 4 and a sewage drainage ditch 5, and their mutual combination forms a closed cycle The water cleaning system cleans the ground dust particles in the mine tank area to ensure the bottom surface is clean.

[0040] from figure 1 The ore trough area observed from the top view angle, the ore trough is arranged along the left and right directions, with an unloading car on it, and a conveying device is installed at the left end of the ore trough to send the raw ore in the ore trough to the blast furnace. The conveying device has a transmission chamber , to control the operation of the conveying device; there are mineral powder bins and coke powder bins on both sides of the conveying device to supply mineral powder and coke powder for the ore t...

Embodiment 2

[0050] The water cleaning and recycling system in the blast furnace mine tank area of this embodiment is optimized based on the layout characteristics of the mine tank area and the characteristics of the materials to be cleaned on the basis of embodiment 1, so as to achieve better cleaning effect. Because most of the mine tank blanking is concentrated on both sides of the mine tank, there is a certain distance from the sewage ditch 5, and the mineral material is heavy and difficult to dissolve in water. Therefore, the cleaning water pressure is very good, and high-power drainage is required. The pump 4 undoubtedly increases the burden of the drain pump 4, even so, the effect is also unsatisfactory.

[0051] For this, combine figure 1 , Figure 4 with Figure 5 As shown, in this embodiment, on the ground of the ore trough area, the height of the extension of the sewage ditch 5 on both sides of the upper and lower sides gradually decreases with the ore trough as the center, ...

Embodiment 3

[0056] The water cleaning and recycling system in the blast furnace pit area of this embodiment is further optimized and designed on the basis of Embodiment 2 to treat suspended dust in the air.

[0057] Due to the unavoidable generation of dust during the operation of the mine tank area, the dust concentration in the air is high, and the operating environment is relatively harsh; even if the ground has been cleaned, as the dust in the air falls, the ground dust will continue to accumulate. It also affects the cleaning effect. Therefore, the present embodiment is provided with a plurality of spray nozzles 9 at intervals along one side of the drain ditch 5 in the three cleaning areas. Spraying water mist in the air can make the dust in the air settle quickly, which is conducive to improving the working environment of the mine tank, improving the air quality, and reducing the continuous dust falling to the ground. The purpose that the spray nozzle 9 is arranged along the drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com