Using-procedure-free low-nitrogen condensation type fuel gas steam boiler

A gas-fired steam and condensing technology, applied in steam boilers, water tube steam boilers, steam generation, etc., can solve problems such as low thermal efficiency, waste of energy, environmental pollution, etc., and achieve extended service life, reduced use site requirements, and separation effects good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

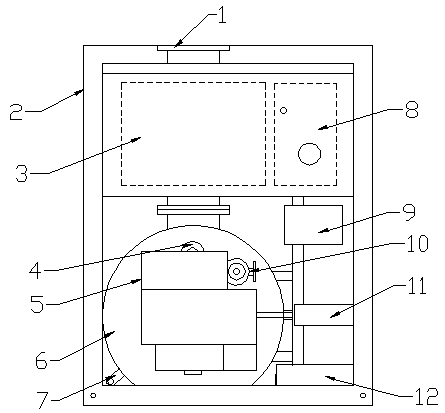

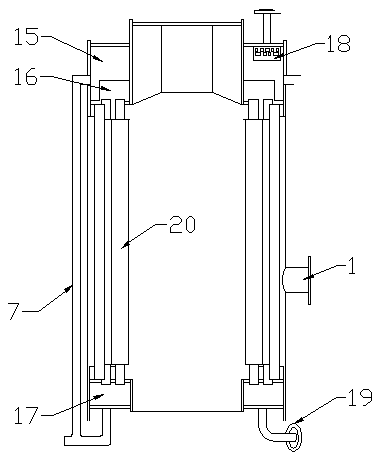

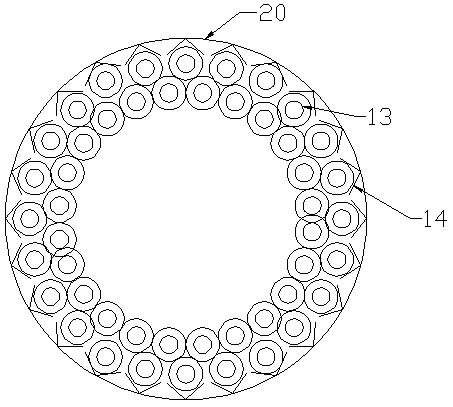

[0026] Example: such as Figure 1-3 As shown, the present invention is a low-nitrogen condensing gas-fired steam boiler free of procedures, including a boiler skid base 2 and a boiler body 6 fixed on the boiler skid base 2. The structure of the boiler body 6 is that the upper and lower annular headers The vertical water pipes gathered at both ends are arranged in two rings. The vertical pipe 20 adopts finned tubes. This design expands the combustion chamber, and the finned tubes greatly increase the radiation area of heat transfer. The flue gas is evenly distributed along the 360° ° To the arranged water pipes for radiation circulation and heat exchange, use a smoke baffle between every two tubes of the outer ring tube to reduce the flow area of the smoke gas, thereby speeding up the flow rate of the smoke and improving convective heat transfer, and finally flow to the rear Smoke outlet; an integrated economizer and condenser 3 and a water tank 8 are arranged above the boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com