DEA cross model energy efficiency analysis method based on principal component fusion

An analysis method and model technology, applied in data processing applications, instruments, calculations, etc., can solve the problems of guidance, not considering the impact of PTA energy efficiency, not considering the role of energy consumption indicators, etc., to achieve accurate analysis and evaluation, improve differentiation degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

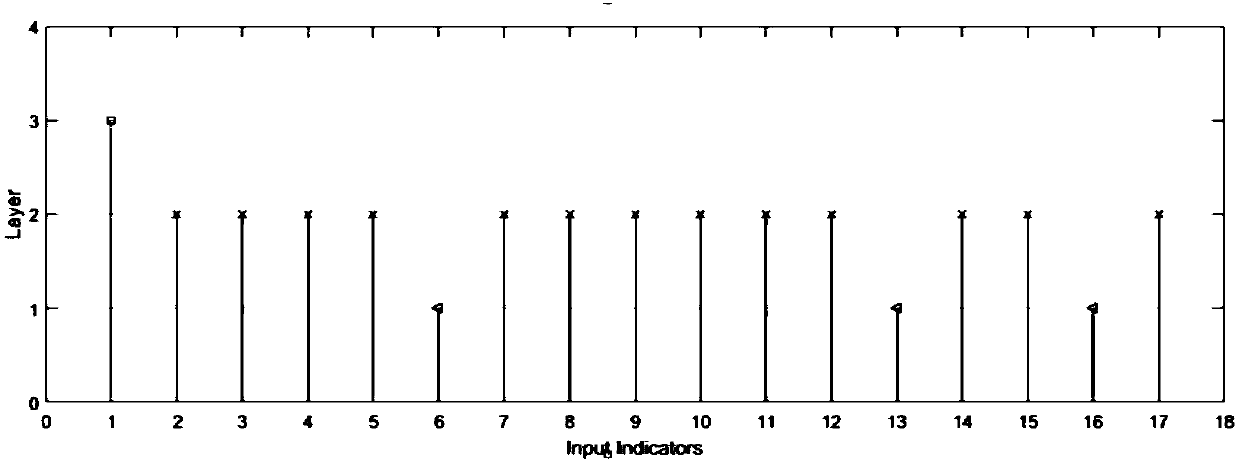

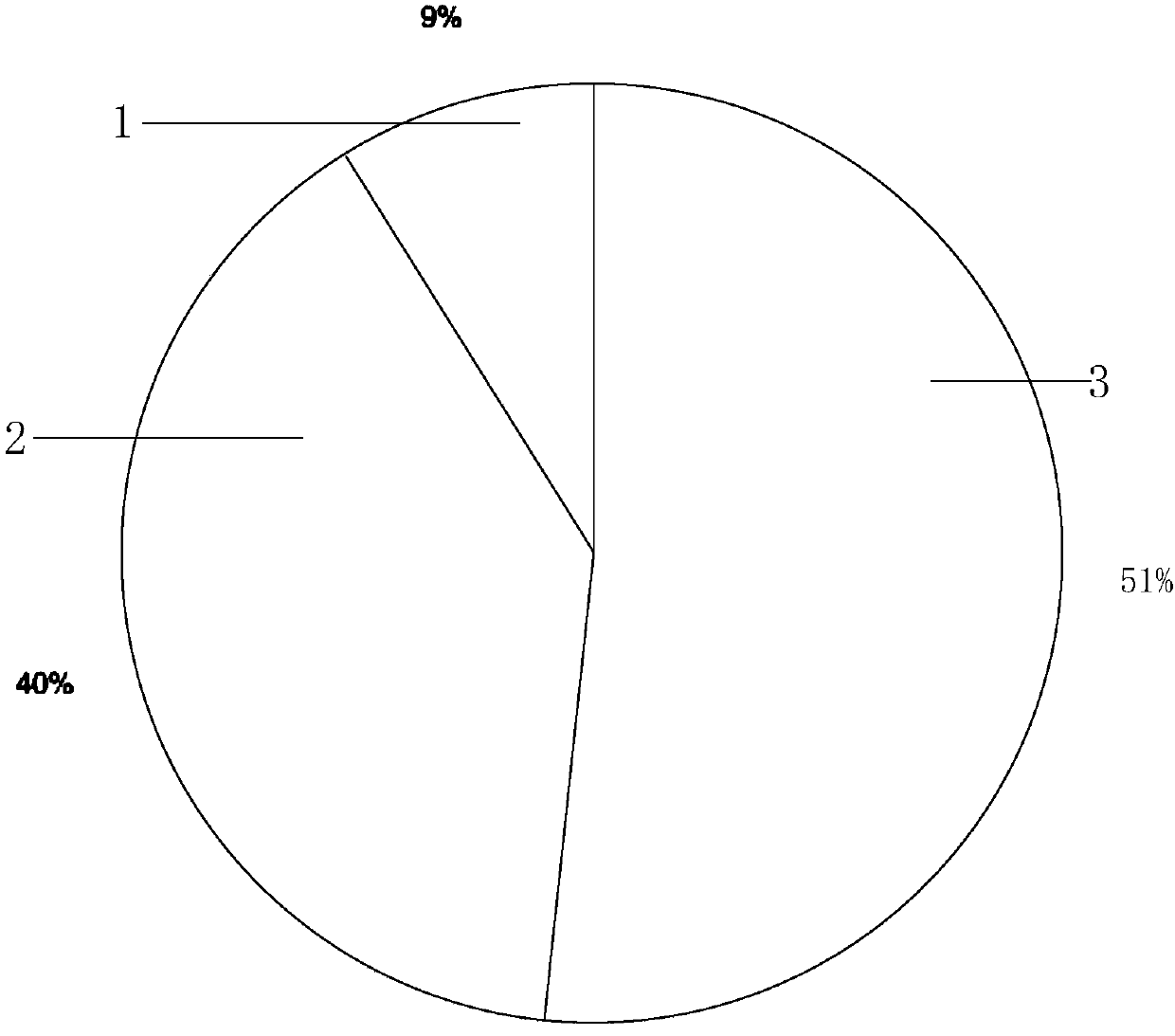

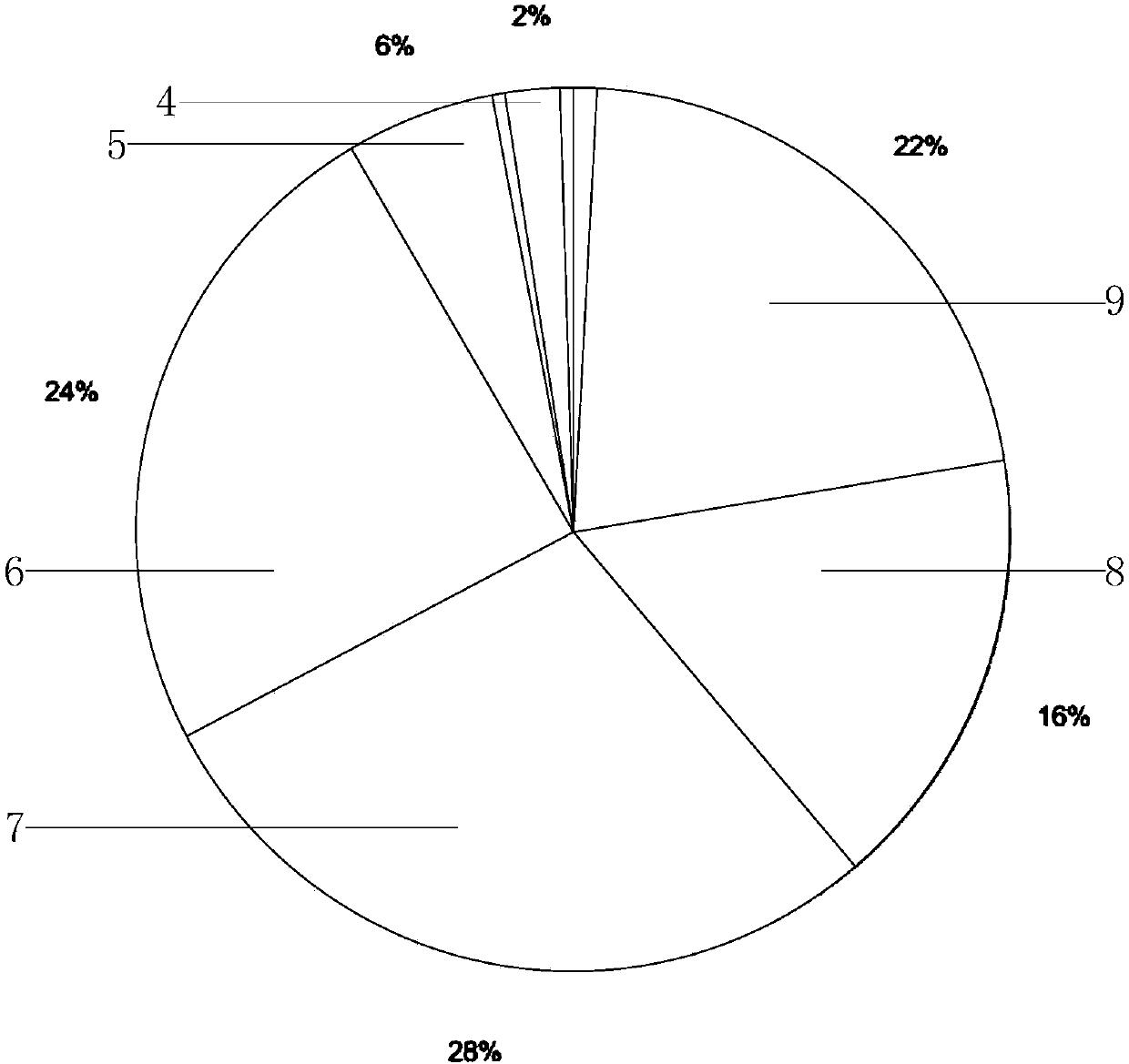

[0025] This embodiment provides a DEA cross-model energy efficiency analysis method based on principal component fusion, including: obtaining 20 sets of production data of purified terephthalic acid production equipment; obtaining the production data of the phthalic acid production equipment according to the 20 sets of production data Input index, described input index comprises 17 factors that affect the consumption of acetic acid, and described 17 factors comprise feed rate, the first temperature, the first reflux flow, the second reflux flow, the 3rd reflux flow, the second temperature, Reboiler steam flow rate, temperature in the first tower, temperature in the second tower, temperature in the third tower, temperature in the fourth tower, temperature in the fifth tower, temperature in the sixth tower, temperature in the seventh tower, temperature in the eighth tower The temperature in the tower, the temperature in the ninth tower and the temperature in the tenth tower. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com