Variable speed drive system and method for starting and/or operating variable speed drive system

A drive system, variable technology, applied in the direction of motor speed or torque control, control system, starter of a single synchronous machine, etc., can solve the problem that the speed controllable drive or differential drive cannot be controlled, and the wear of the main drive , impact and other issues, to achieve the effect of favorable and economical design and less wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

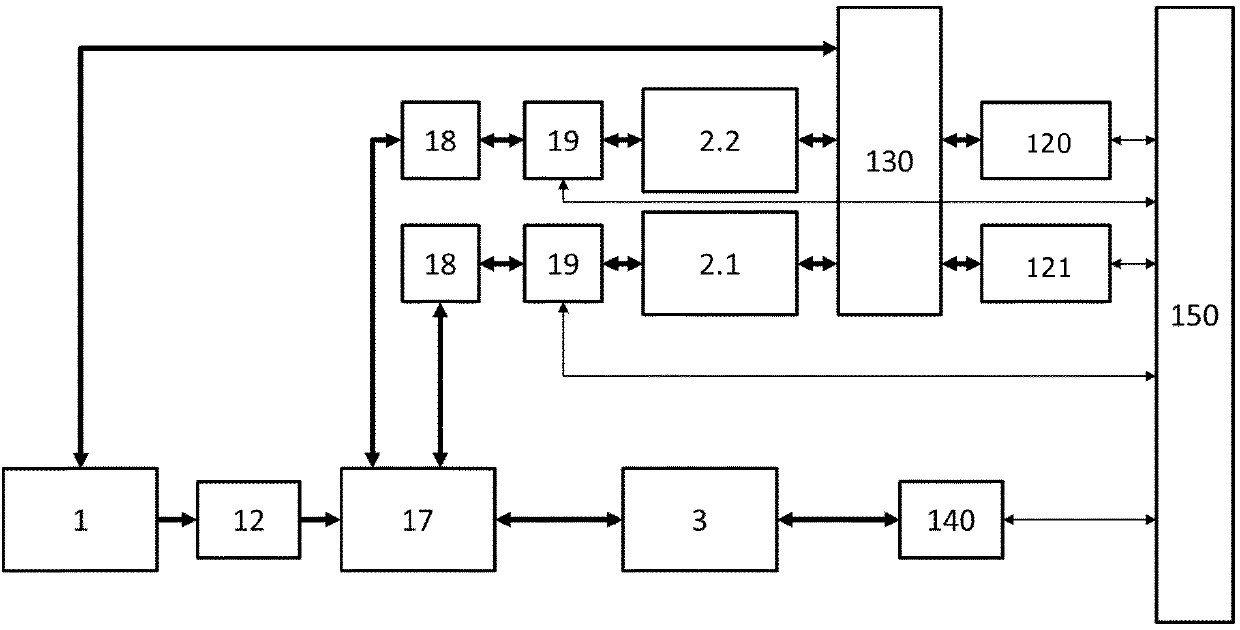

[0071] figure 1 The schematic diagram of the variable speed drive system shown shows a transmission unit 17 having a central input shaft on the driving machine 1 , preferably an electric induction machine, and a central output shaft on the driven machine 3 .

[0072] The transmission unit 17 is preferably designed as a planetary gear having a sun gear 7 , a planet carrier 10 (hereinafter also referred to as “planet”) with planet gears 5 and a ring gear 4 . Thus, coaxiality between the input (driving) and output (driven) shafts is achieved.

[0073] The two regulating machines 2 . 1 , 2 . 2 are coupled to the transmission unit 17 via branched corresponding transmission stages 18 and can thus supply power to the drive machine 1 . Preferably, the two regulating machines 2.1, 2.2 are independent speed controllable electric motors.

[0074] The connection of the input and output shafts to the planetary gears can be done in different ways, thus different types of coincident gears ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com