Comprehensive dust inhibition system

A technology of dry fog and ejector, which is applied in the fields of grain processing, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of dust in the ore crushing system, and achieve the effects of effective dust suppression, high concentration, and accelerated decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

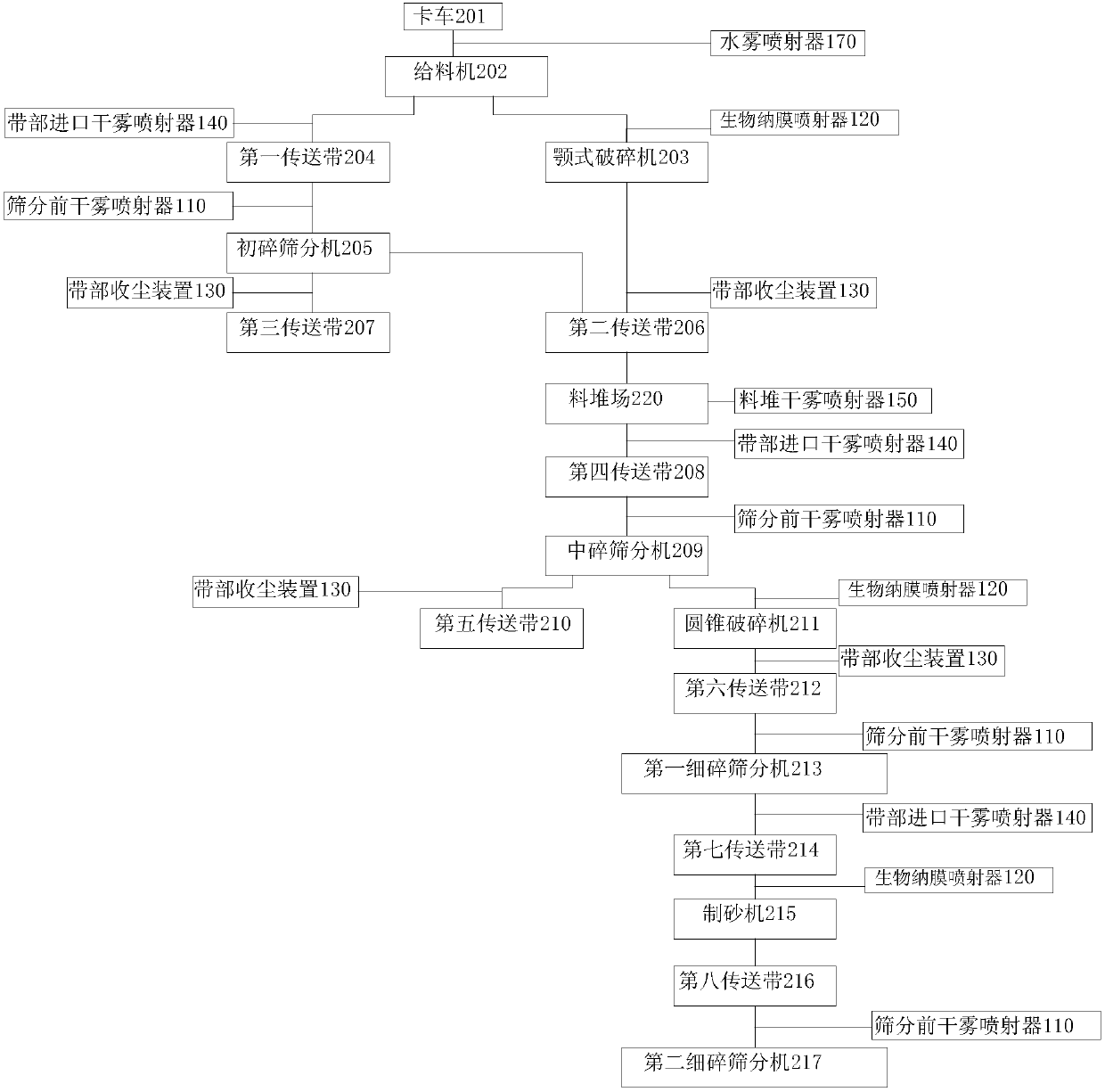

[0047] Such as figure 1 As shown, the comprehensive dust suppression system of this embodiment is used to suppress the dust caused by the work of the material crushing system. The crushing system includes a screening machine for screening materials, a crusher for crushing materials and a conveyor belt for conveying materials;

[0048] The comprehensive dust suppression system includes: a dry mist injector 110 arranged before screening of the sieving machine; a bionanofilm injector 120 arranged at the feed port of the crusher.

[0049] Because the particle size of the material is reduced after the crusher pulverizes the material, and dust is generated inside the crusher, the bionanofilm injector 120 installed at the feed port of the crusher can spray the bionanofilm on the material, and the bionanofilm When the material enters the crusher, the bionanofilm is a double ionosphere membrane. The dust generated during the crushing process will be absorbed by the bionanofilm, thereby...

Embodiment 2

[0058] Such as figure 1 As shown, an ore crushing system includes a rough crushing process, a medium crushing process and a fine crushing process arranged in sequence, and the ore crushing system is used for crushing rocks;

[0059] Coarse crushing process includes the following steps:

[0060] 1) The ore is transported to the construction site by the truck 201, and the truck 201 dumps the material into the feeder 202;

[0061] 2) The material with a particle size greater than 100 mm in the feeder 202 is poured into the jaw crusher 203 for primary crushing, and the material with a particle size of 100 mm or less in the feeder 202 is poured into the first conveyor belt 204;

[0062] 3) The material on the first conveyor belt 204 enters the primary crushing and screening machine 205, and the primary crushing and screening machine 205 screens out the material with a particle size greater than 50 mm and the primary crushed material of the jaw crusher 203 enters the stack through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com