Hydraulic assembly

A hydraulic unit and hydraulic technology, applied in the direction of hydraulic steering gear, steering mechanism, fluid steering mechanism, etc., can solve the problems of motor mechanical power limitation, easy failure, and increased damage probability of hydraulic electric steering system, so as to improve reliability The effect of reducing the damage probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

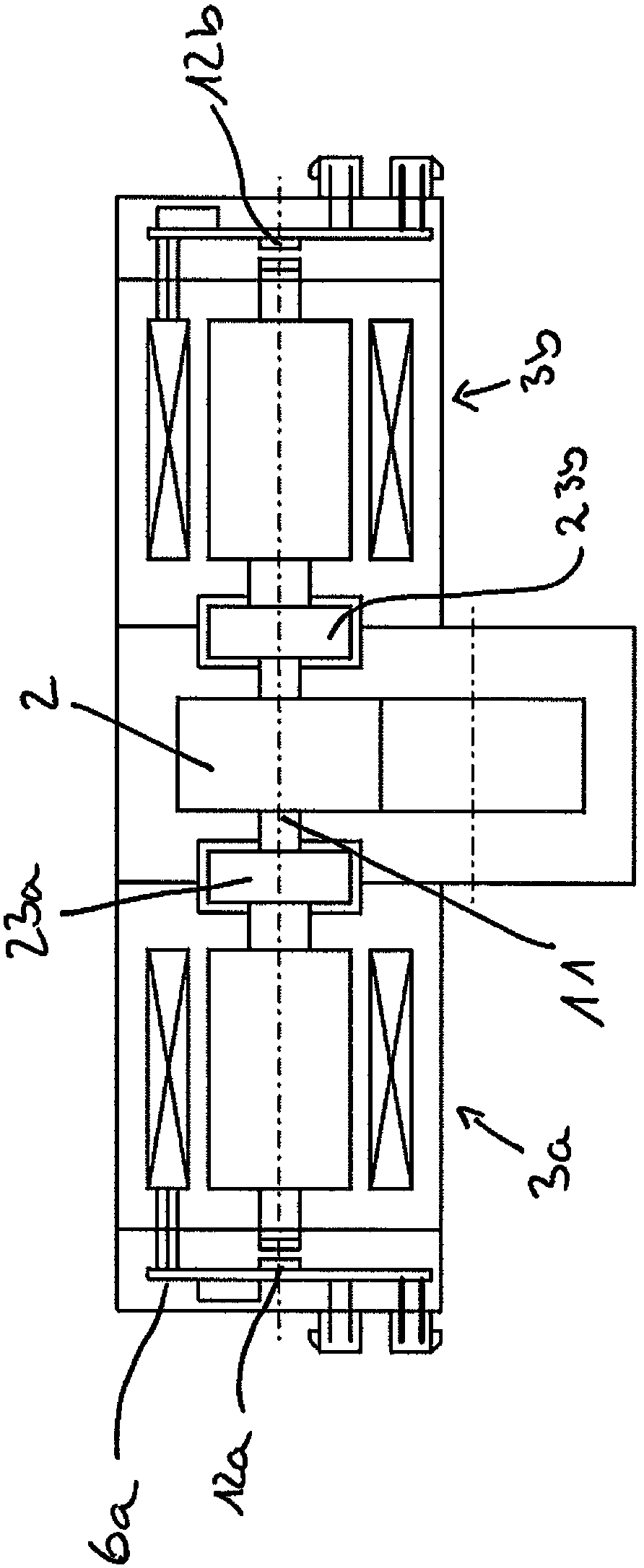

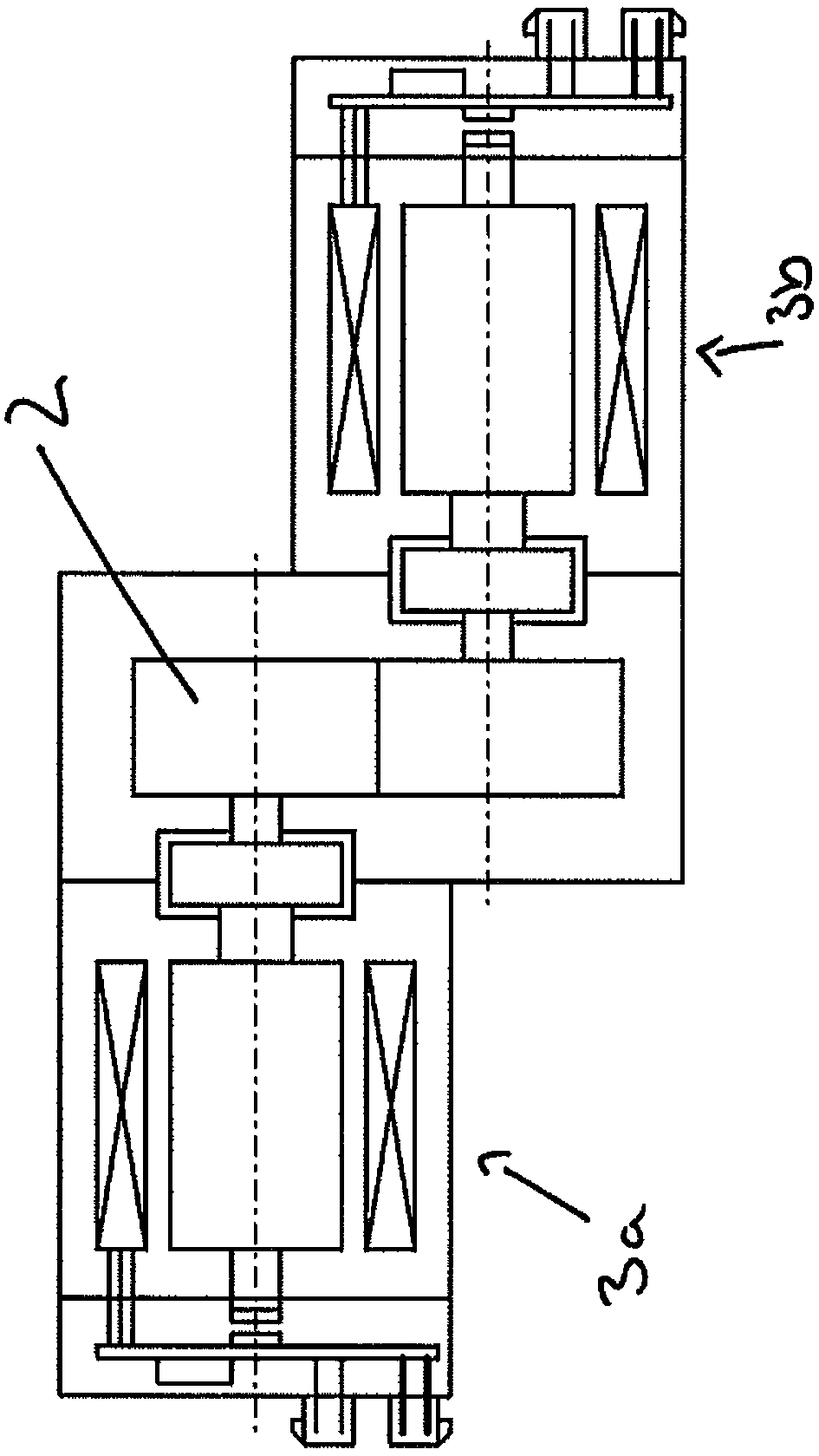

[0056] exist Figure 1-4 In , the same reference numerals represent the same parts or parts with the same function.

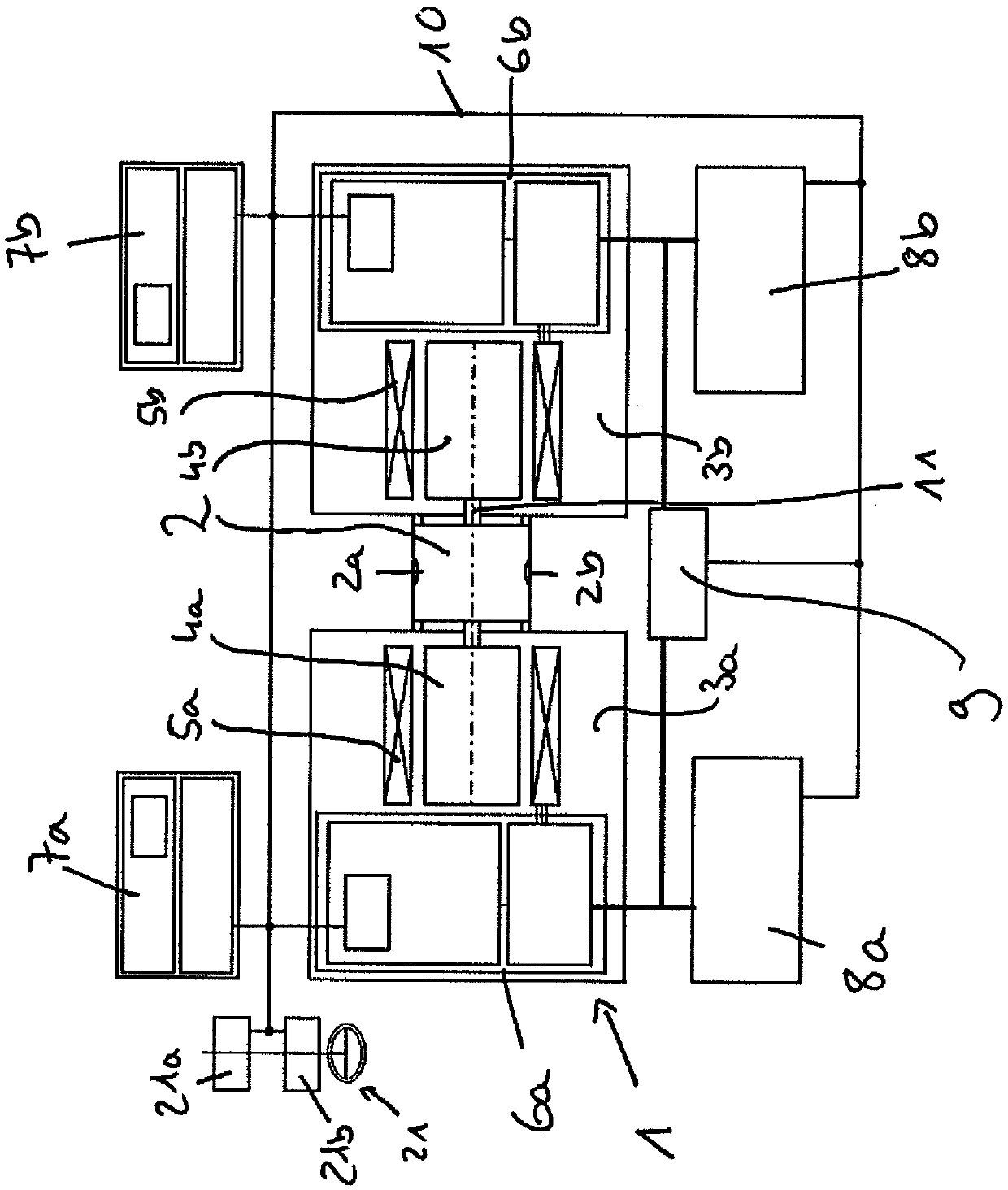

[0057] figure 1 A schematic diagram of a first embodiment of the hydraulic unit of the invention is shown.

[0058] The hydraulic unit 1 comprises a hydraulic pump 2 and two drive motors 3a, 3b. The drive motors 3a, 3b are each designed with a rotor 4a, 4b and a stator 5a, 5b and each include a motor controller 6a, 6b. Here, the two drive motors 3a, 3b are designed as brushless motors.

[0059] In a redundant embodiment, a control circuit 7a, 7b is also provided here for each of the two drive motors.

[0060] The hydraulic pump 2 is configured as a gear pump with a double-side drive structure. Via the two ports 2a, 2b the hydraulic fluid reaches the hydraulic cylinder 25 as Figure 4 shown. The hydraulic pump 2 is arranged between the two drive motors 3a, 3b.

[0061] The hydraulic unit with the two drive motors 3 a , 3 b is supplied by a power supply 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com