Emulsified asphalt waterproof coating and preparation method thereof

A waterproof coating and emulsified asphalt technology, applied in asphalt coatings, coatings, etc., can solve the problems of poor waterproof performance of waterproof materials, easy soft swelling, matrix peeling, etc., to achieve good elasticity and weather resistance, not easy to crack and warp , Strong bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

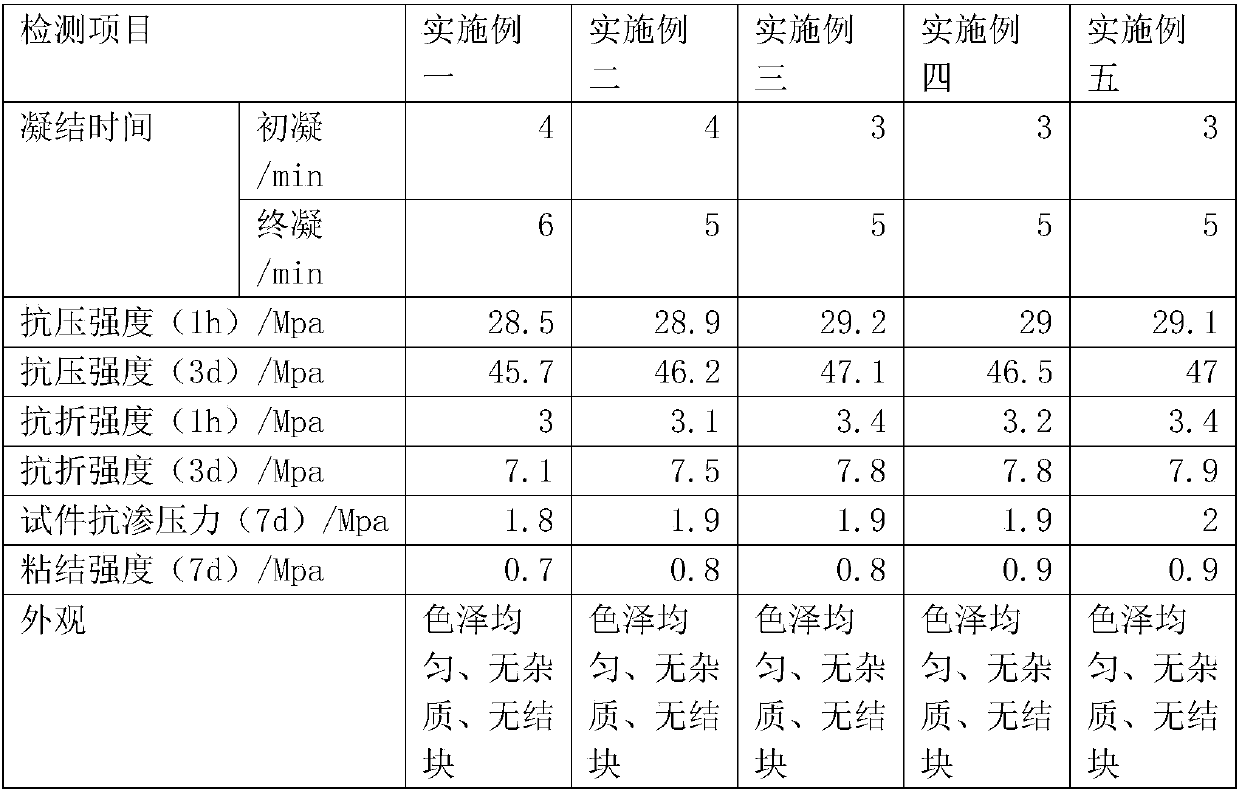

Embodiment 1

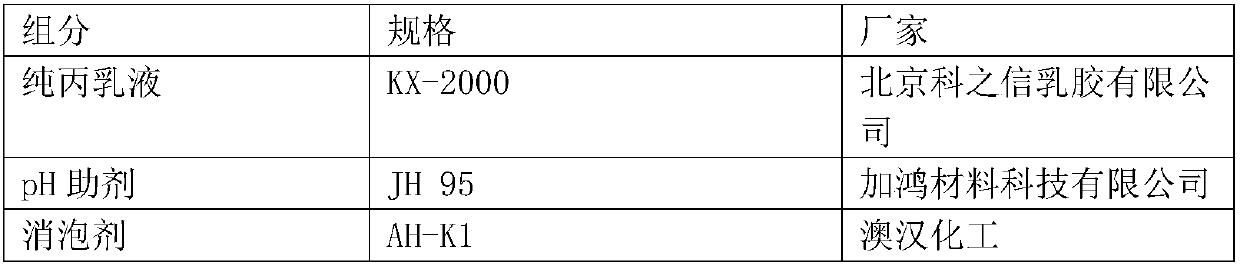

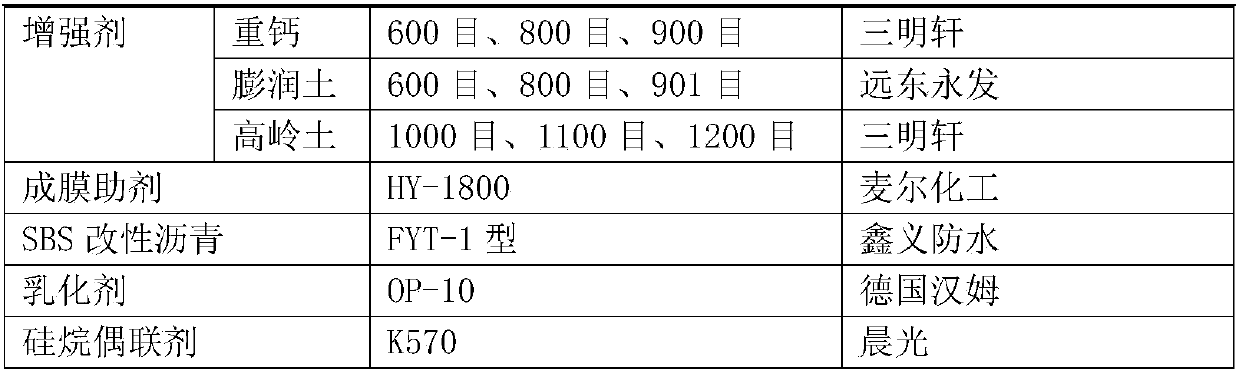

[0038] Embodiment one: a kind of preparation method of emulsified asphalt waterproof coating comprises the following steps:

[0039] (1) 280kg pure acrylic emulsion, 0.8kgpH auxiliary agent and 1.5kg defoamer were stirred and mixed for 5min to prepare an aqueous mixture, and the rotating speed was 500r / min;

[0040] (2) Add 130kg800 mesh heavy calcium, 70kg600 mesh bentonite and 40kg1000 mesh kaolin to the water-based mixture and stir and mix for 20 minutes to prepare the reinforced mixture, with a rotating speed of 800r / min;

[0041] (3) Add 1.5kg defoamer and 3kg film-forming aid in the reinforcing mixture to make the primary mix;

[0042] (4) Add 380kg of SBS modified asphalt, 8kg of emulsifier and 3kg of silane coupling agent to the initial mixture and stir and mix for 30min at a speed of 1000r / min to prepare emulsified asphalt waterproof coating.

Embodiment 2

[0043] Embodiment two: a kind of preparation method of emulsified asphalt waterproof coating comprises the following steps:

[0044] (1) 290kg pure acrylic emulsion, 1kgpH auxiliary agent and 2kg defoamer were stirred and mixed for 5min to prepare water-based mixture, and the rotating speed was 600r / min;

[0045] (2) Add 140kg800 mesh heavy calcium, 75kg800 mesh bentonite and 50kg1200 mesh kaolin into the water-based mixture and mix for 20 minutes to prepare the reinforced mixture at a speed of 900r / min;

[0046] (3) Add 2kg defoamer and 4kg film-forming aid in the reinforcing mixture to obtain the primary mix;

[0047] (4) Add 390kg of SBS modified asphalt, 9kg of emulsifier and 4kg of silane coupling agent to the initial mixture and stir and mix for 30min at a speed of 1000r / min to prepare emulsified asphalt waterproof coating.

Embodiment 3

[0048] Embodiment three: a kind of preparation method of emulsified asphalt waterproof coating comprises the following steps:

[0049] (1) 300kg pure acrylic emulsion, 1kgpH auxiliary agent and 2kg defoamer were stirred and mixed for 5min to prepare an aqueous mixture, and the rotating speed was 600r / min;

[0050] (2) Add 150kg600mesh heavy calcium, 75kg900mesh bentonite and 50kg1200mesh kaolin into the water-based mixture and mix for 20min to prepare the reinforced mixture, the rotating speed is 900r / min;

[0051] (3) Add 2kg defoamer and 5kg film-forming aid in the reinforcing mixture to make the primary mix;

[0052] (4) Add 400kg of SBS modified asphalt, 10kg of emulsifier and 5kg of silane coupling agent to the initial mixture and stir and mix for 30min at a speed of 1000r / min to prepare emulsified asphalt waterproof coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com