RFID-based shipyard part assembly-welding production line logistics tracking system

A tracking system and production line technology, applied in the direction of manufacturing computing systems, computer parts, collaborative devices, etc., can solve the problems that the information collection method cannot be tracked in real time, affect the process control of the assembly line, work, and low production efficiency, and achieve the realization of The effect of intelligent identification and information management, improving logistics management level and production efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

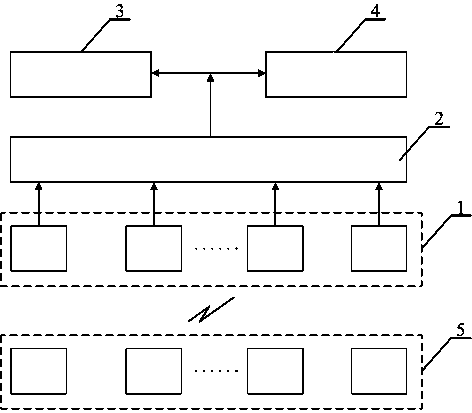

[0009] See attached figure 1 , the present invention is made up of RFID signal reading device 1, PLC main frame 2, operation interface 3, electronic Kanban 4 and RFID electronic label 5, and described RFID signal reading device 1 is several and is one with each welding station of production line 7 One-to-one correspondence setting; the RFID electronic tags 5 are several and are set in one-to-one correspondence with each welding workpiece; the PLC host 2 is connected with several RFID signal reading devices 1 and the operation interface 3 and the electronic kanban 4 by cables , the RFID signal reading device 1 and the RFID electronic tag 5 are inductively coupled.

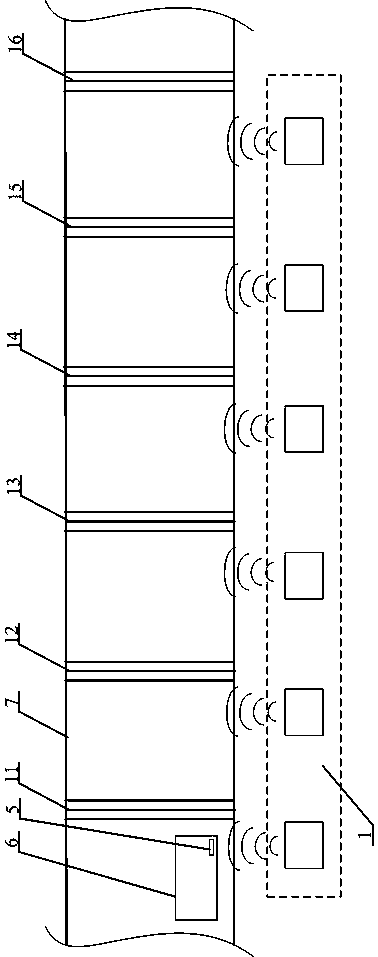

[0010] See attached figure 2 , this is set up to operate on the production line 7 for assembly and welding of components in this way. The production line 7 is equipped with six stations, which are respectively the jigsaw station 11, the material preparation and assembly station 12, the assembly station 13, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com