Trench gate IGBT device with high anti-short circuit capability and preparation method thereof

A trench gate and manufacturing method technology, applied in the field of microelectronics, can solve the problems of reducing the short-circuit resistance of the device, affecting the normal application of the device, increasing the IGBT current, etc., and achieving the effect of improving the short-circuit resistance, compact structure and reducing the saturation current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific drawings and embodiments.

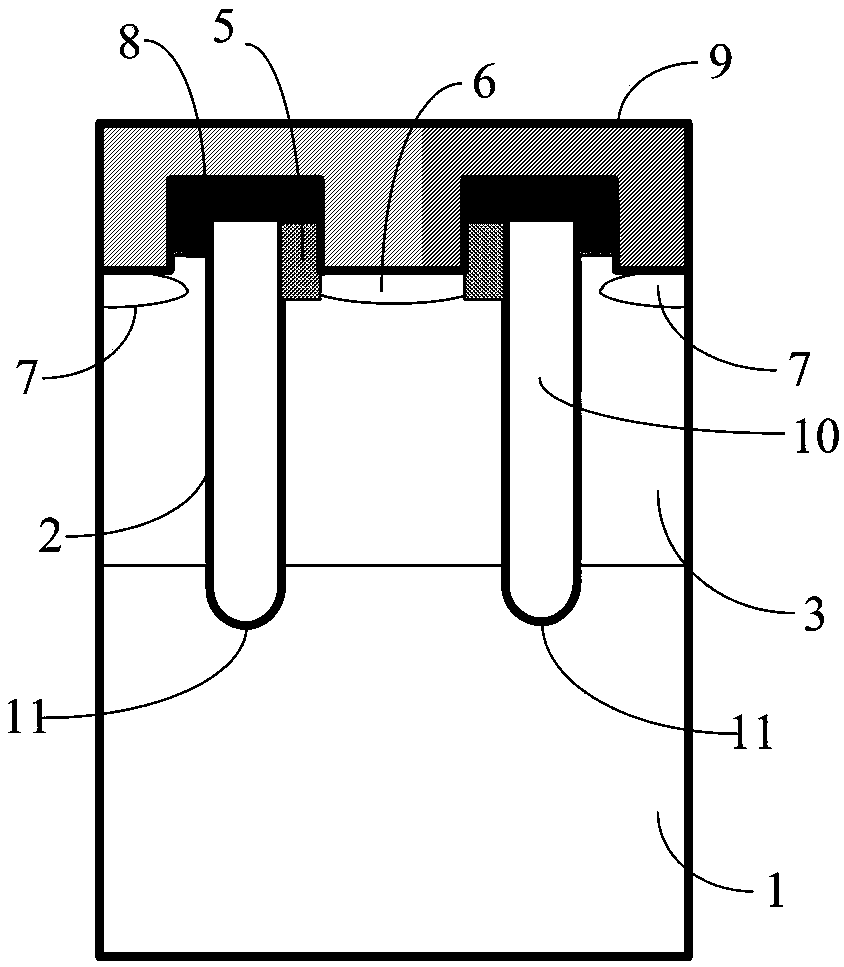

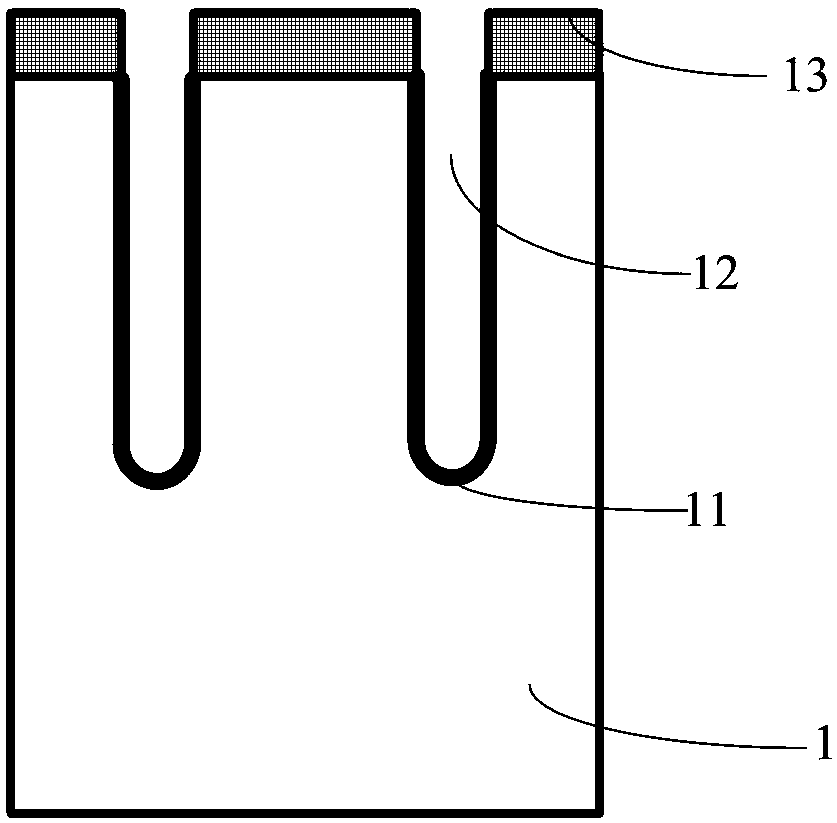

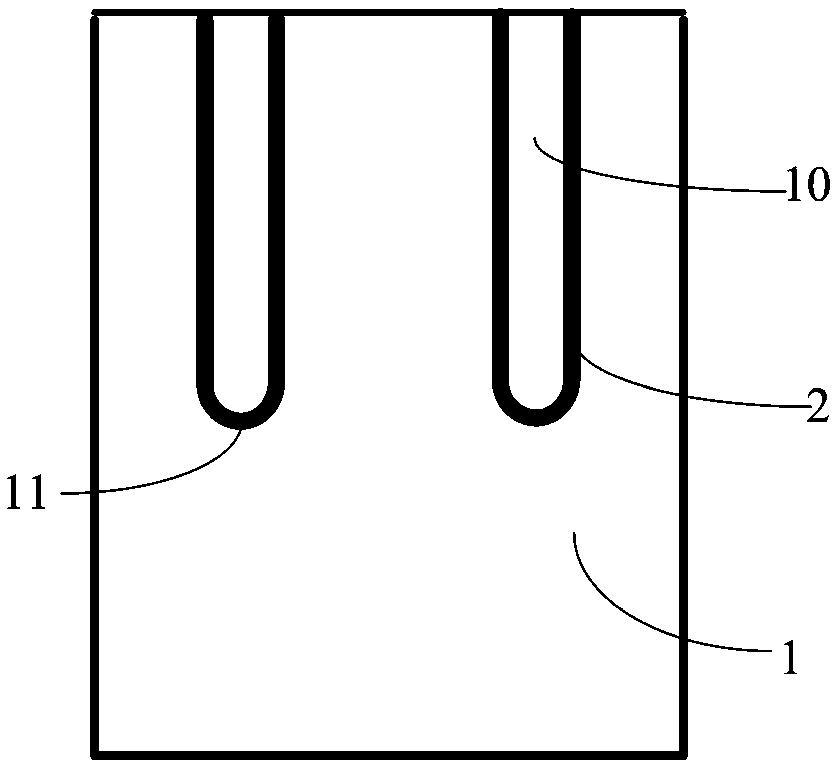

[0039] Such as figure 1 and Figure 10Shown: In order to reduce the channel density of the trench gate IGBT, reduce the saturation current, and effectively improve the short-circuit resistance capability of the trench gate IGBT without affecting the withstand voltage and parasitic capacitance of the IGBT device, the N-type IGBT device is used as the For example, the present invention includes a semiconductor base and a cell region located in the central region of the semiconductor substrate, and the semiconductor substrate includes an N-type base region 1 and a P-type base region 3 directly above the N-type base region 1;

[0040] The cells in the cell area include two adjacent cell grooves 11, the cell grooves 11 are located in the P-type base region 3, and the depth of the cell grooves 11 extends into the N below the P-type base region 3. In the base region...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com