Yarn traversing device comprising motor driver and finger guide

A motor drive, traversing device technology, used in transportation and packaging, function indication, conveying filamentous materials, etc., to achieve the effect of improving overall effectiveness, optimizing overall effectiveness, and rapid intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

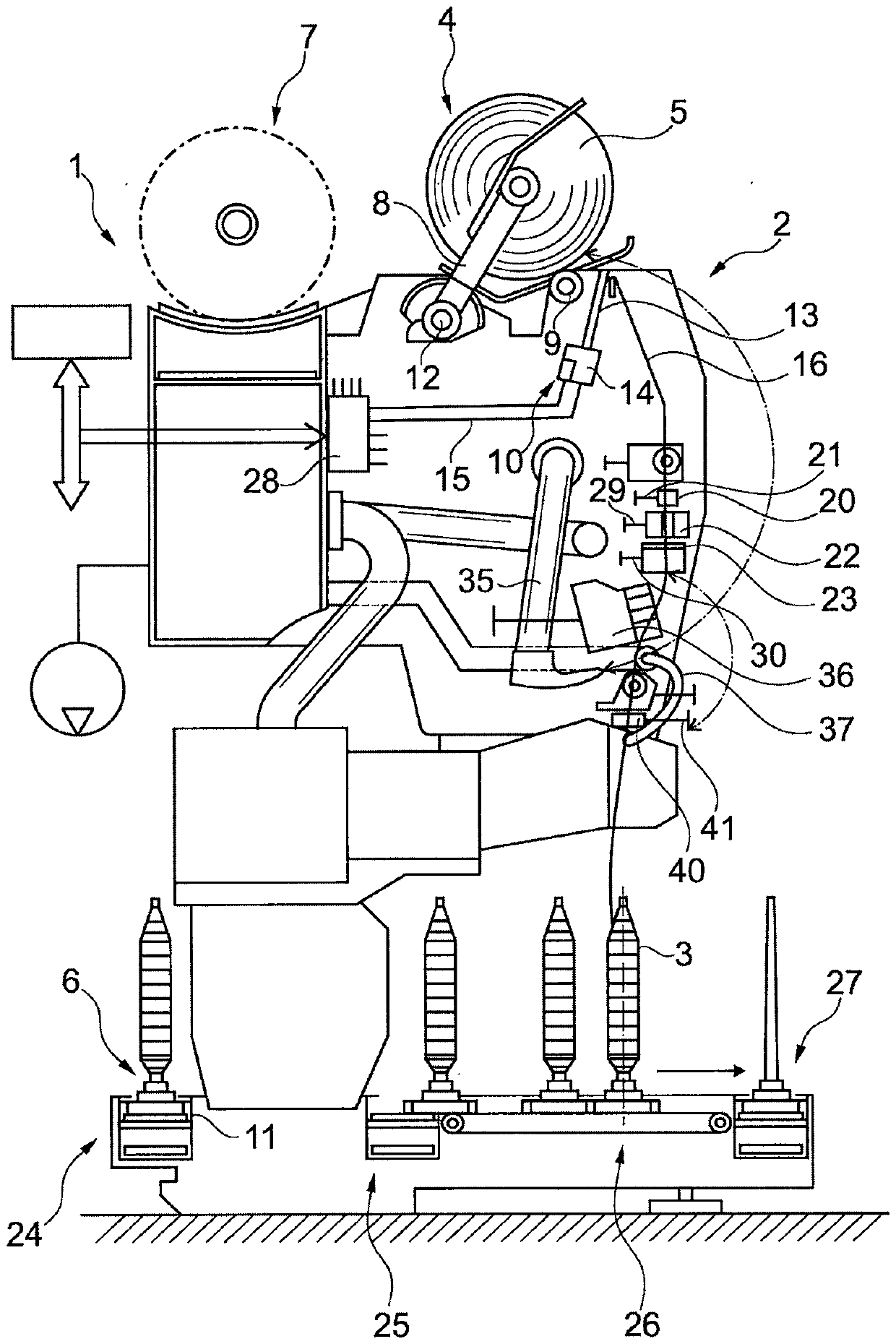

[0044] figure 1 A side view of a workstation 2 of a textile machine producing wound bobbins, in the present case a winding machine 1 , is schematically shown. As is known, such winding machines 1 comprise a plurality of such work stations 2 of identical construction between their (not shown) end frames.

[0045] As is also known and therefore not explained in more detail, at said workstation 2 the spinning bobbins 3 produced on the ring spinning machine are rewound into bulk winding bobbins 5, which are after their production by means of ( not shown) service unit (for example a cross-wound bobbin changer) to the wound bobbin conveyor 7 at the machine length and then to the bobbin loading station at the machine end etc.

[0046] Such a winding machine 1 also generally includes logistics equipment in the form of a bobbin and bobbin transport system 6 . In said bobbin and tube transport system 6 , spinning packages 3 or empty bobbins circulate on a transport plate 11 . figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com