Polypropylene composite and preparation method thereof

A composite material, polypropylene technology, applied in the field of polypropylene materials, can solve problems such as unfavorable lightweight, low elastic modulus of polypropylene materials, and increased polypropylene density, and achieve the effects of improving rigidity, enhancing interaction, and reducing use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

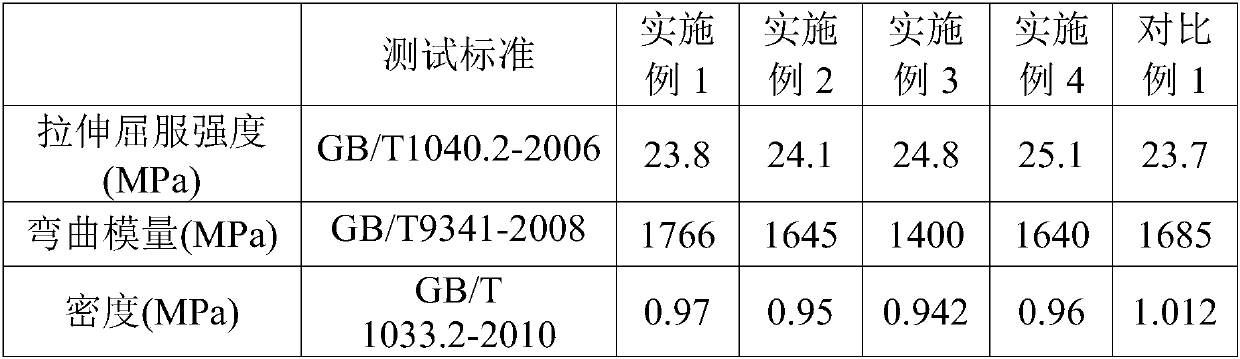

Examples

Embodiment 1

[0021] First dry 20 parts of inorganic powder magnesium sulfate whiskers (H803i, Milliken Company) in an oven at 150°C for 2 hours, weigh 80 parts of polypropylene (630, Yangzi Petrochemical Co., Ltd.; 1215C, Yangzi Petrochemical Co., Ltd. company, the two are blended according to 1:1), 0.2 parts of aluminate coupling agent (TC-130, Shenzhen Haicheng Xingye Technology Co., Ltd.), 0.1 part of antioxidant (09 additives, Beijing Jihaichuan Technology Development Co., Ltd., the main components are 1010 and 168, the same below) mixed evenly in a high-speed mixer and then added to a twin-screw extruder. ℃, 220°C, 220°C, 190°C, the same below, abbreviated), melt blending, extrusion, cooling, and pelletizing to obtain polypropylene composite materials.

Embodiment 2

[0023] First dry 10 parts of inorganic powder magnesium sulfate whiskers (H803i, Milliken Company) in an oven at 150°C for 2 hours, weigh 90 parts of polypropylene (630, Yangzi Petrochemical Co., Ltd.; 1215C, Yangzi Petrochemical Co., Ltd. company, the two are blended according to 1:1), 0.02 parts of silane coupling agent (KH-570, Shenzhen Haicheng Xingye Technology Co., Ltd.), 0.3 parts of antioxidant (09 additives, Beijing Jihaichuan Technology Development Co., Ltd. ) is mixed uniformly in a high-speed mixer, then added to a twin-screw extruder, melted, blended, extruded, cooled, and pelletized at a temperature range of 160-220°C to obtain a polypropylene composite material.

Embodiment 3

[0025] First dry 5 parts of inorganic powder magnesium sulfate whiskers (H803i, Milliken Company) in an oven at 150°C for 2 hours, weigh 95 parts of polypropylene (630, Yangzi Petrochemical Co., Ltd.), 0.1 part of titanate Coupling agent (TC-201, Shenzhen Haicheng Xingye Technology Co., Ltd.), 0.3 parts of antioxidant (09 auxiliary agent, Beijing Jihaichuan Technology Development Co., Ltd.) are mixed in a high-speed mixer and then added to the twin-screw extruder , in the temperature range of 160-220°C, melt blending, extrusion, cooling, and pelletizing to obtain polypropylene composite materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com