Low-odor polyamide composition and preparation method thereof

A polyamide composition and low-odor technology, applied in the field of low-odor polyamide composition and its preparation, can solve problems such as odor generation, and achieve the effect of improving odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

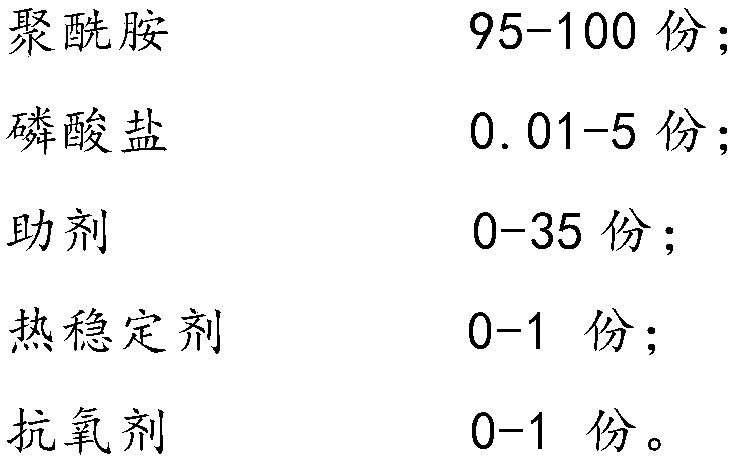

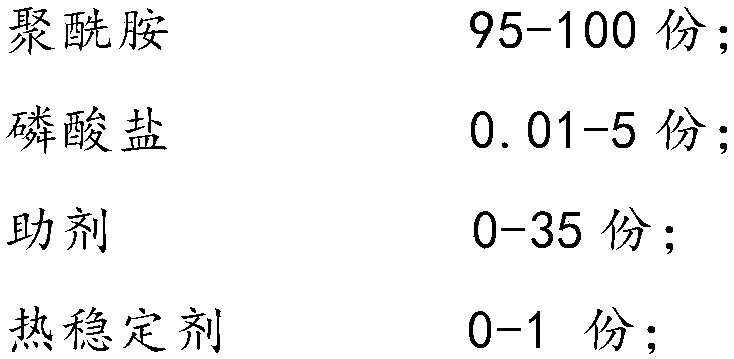

[0037] Prepare raw materials according to the following components and parts by weight thereof:

[0038] PA66 99kg;

[0039] Disodium hydrogen phosphate 1kg;

[0040] The low-odor polyamide composition obtained by granulating through the above-mentioned blending extrusion process is further passed through the odor removal process of the present invention, and the odor removal process includes placing the initially obtained low-odor polyamide composition in a vacuum tank and performing the following steps: step:

[0041] (1) Use nitrogen gas to replace the air inside the tank, repeat the operation 3 times, and remove the oxygen in the air;

[0042] (2) Seal and draw a vacuum so that the internal pressure of the tank is less than or equal to 133 Pascals;

[0043] (3) The low-odor polyamide composition inside the vacuum tank was heated by the heating coil in the tank body, so that the temperature thereof reached 60° C., and treated by a constant temperature method for 120 minu...

Embodiment 2

[0045] Prepare raw materials according to the following components and parts by weight thereof:

[0046] PA66 99kg;

[0047] Disodium hydrogen phosphate 1kg;

[0048] The low-odor polyamide composition obtained by granulating through the above-mentioned blending and extrusion process is further subjected to the odor removal process of the present invention, and the odor removal process includes placing the initially obtained low-odor polyamide composition in a vacuum tank, and carrying out The following steps:

[0049] (1) Heat the low-odor polyamide composition inside the vacuum tank through the heating coil in the tank body, so that its temperature reaches a temperature of 180° C., and treat it by a constant temperature method for 30 minutes;

[0050] (2) Seal and draw a vacuum so that the internal pressure of the tank is less than or equal to 133 Pascals;

[0051] (3) Replace the air inside the tank with nitrogen gas, repeat the operation 3 times, and remove the oxygen i...

Embodiment 3

[0053] Prepare raw materials according to the following components and parts by weight thereof:

[0054] PA66 99kg;

[0055] Disodium hydrogen phosphate 1kg;

[0056] The low-odor polyamide composition obtained by granulating through the above-mentioned blending and extrusion process is further subjected to the odor removal process of the present invention, and the odor removal process includes placing the initially obtained low-odor polyamide composition in a vacuum tank, and carrying out The following steps:

[0057] (1) Seal and draw a vacuum so that the internal pressure of the tank is less than or equal to 133 Pascals;

[0058] (2) Use nitrogen gas to replace the air inside the tank, repeat the operation 3 times, and remove the oxygen in the air;

[0059] (3) The low-odor polyamide composition inside the vacuum tank was heated by the heating coil in the tank body, so that the temperature thereof reached 120° C., and treated by a constant temperature method for 45 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com