Mixed tooth split type magnetofluid seal device

A magnetic fluid sealing and splitting technology, which is applied to the sealing of the engine, engine components, shafts, etc., can solve the problems of magnetic field leakage and low pressure resistance of the sealing device, so as to strengthen the magnetic flux, improve the pressure resistance and seal. Reliability, the effect of expanding the safe working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

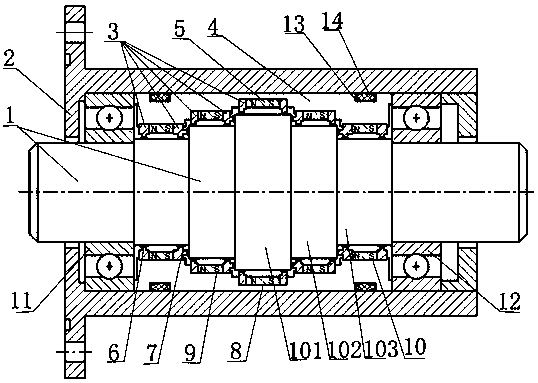

[0028] like figure 1 As shown, the hybrid tooth split magnetic fluid seal device includes a stepped shaft 1, a housing 2, a pole shoe ring 3, a split non-magnetic ring 4, and a permanent magnet ring 5;

[0029] The inner wall of the housing 2 is provided with a split-type non-magnetic ring 5, and the stepped shaft 1 is set in the inner ring surface of the split-type non-magnetic ring 5, and each outer circular surface of the stepped shaft 1 is in contact with Each inner ring surface of split-type non-magnetic body ring 5 corresponds to each other;

[0030] The pole shoe ring 3 and the permanent magnet ring 5 which are in contact with each other are respectively provided on each inner ring surface of the split-type non-magnet ring 5, and the pole shoe ring 3 and the permanent magnet ring 5 are connected to the corresponding stepped shaft There is a gap between the outer ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com