Surface defect detection system for hollow blown containers

A technology for blow molding containers and defect detection, applied in the field of detection systems, can solve the problems of inconspicuous edge features, low efficiency and high missed detection rate of products, and achieve good detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

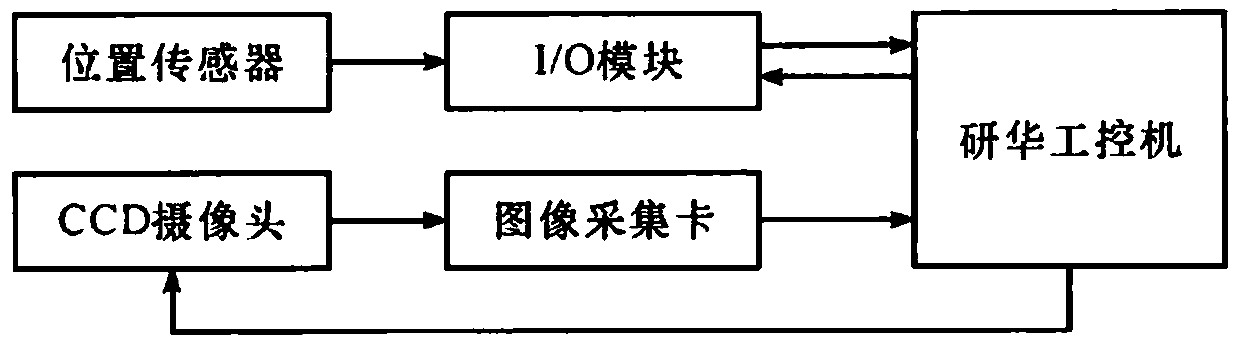

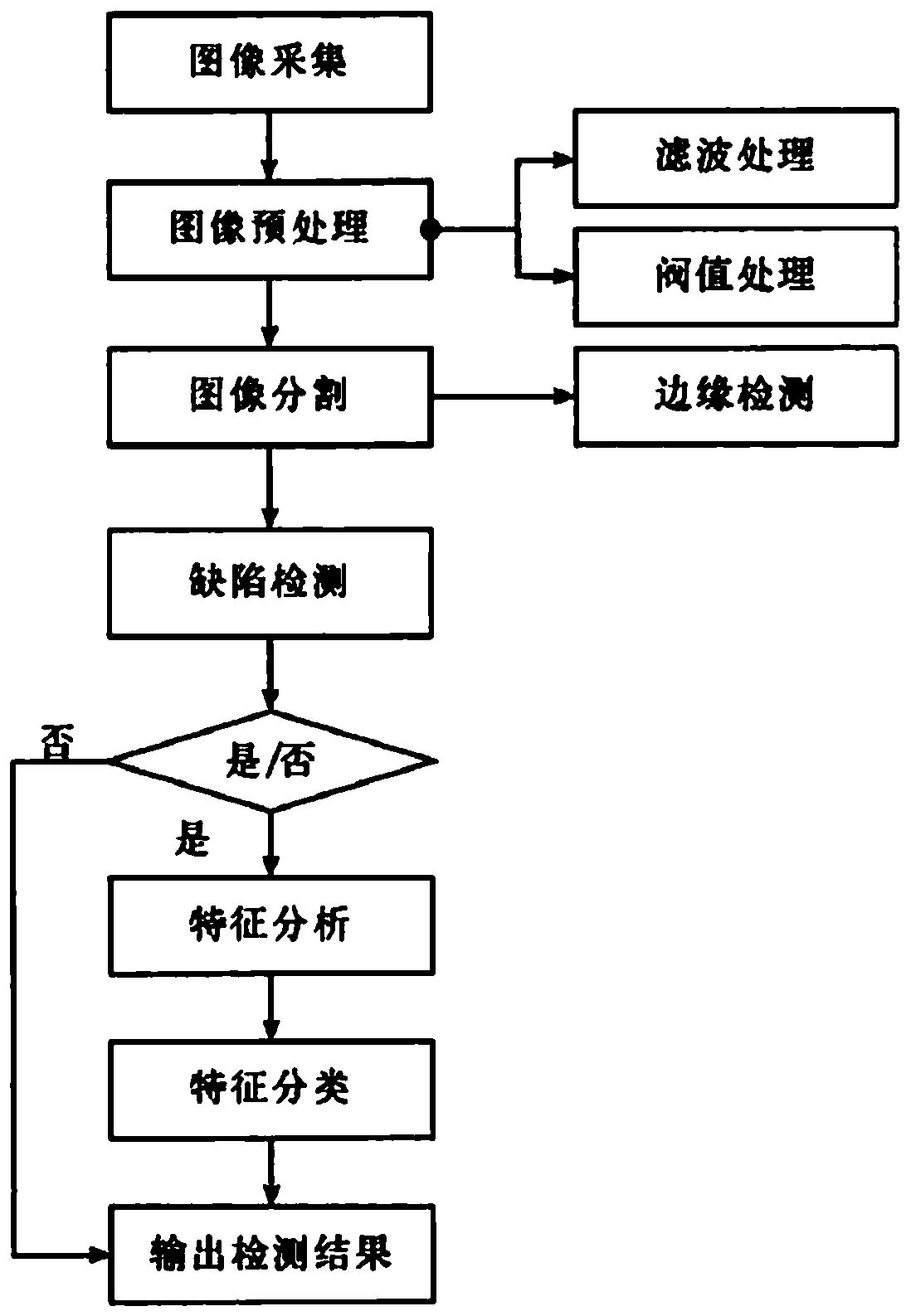

[0017] like figure 1 As shown, the hollow blow molding container surface defect detection system is composed of light source system, image acquisition system, image processing system, measurement and control software system and other parts. This system combines machine vision technology with image processing algorithms, uses Gaussian filter to remove interference, Sobel operator to obtain images with clear edge features, uses least square method to fit contour curves, and finally completes the program writing and detection on LabVIEW result. The light source system is low-angle ring light source and plane light. The image acquisition system uses a 1.3 million-pixel color CCD camera from Baumer Company, a 2 million-pixel color CCD camera from Basler Company, an image acquisition card from NI Company, and a through-beam laser sensor. The image processing system uses Advantech industrial computer. The measurement and control software system is based on the NI-IMAQ vision modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com