Reverse modeling method for structural design parameters of tread patterns

A technology of structural design and reverse modeling, applied in the field of tire industry, can solve problems such as difficult to construct a pattern structure model, most algorithms have single functions, and cannot be developed with tire molds, so as to improve the type, strengthen the degree of intelligence, and reduce the operation process and the effect of waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further explained below in conjunction with the drawings:

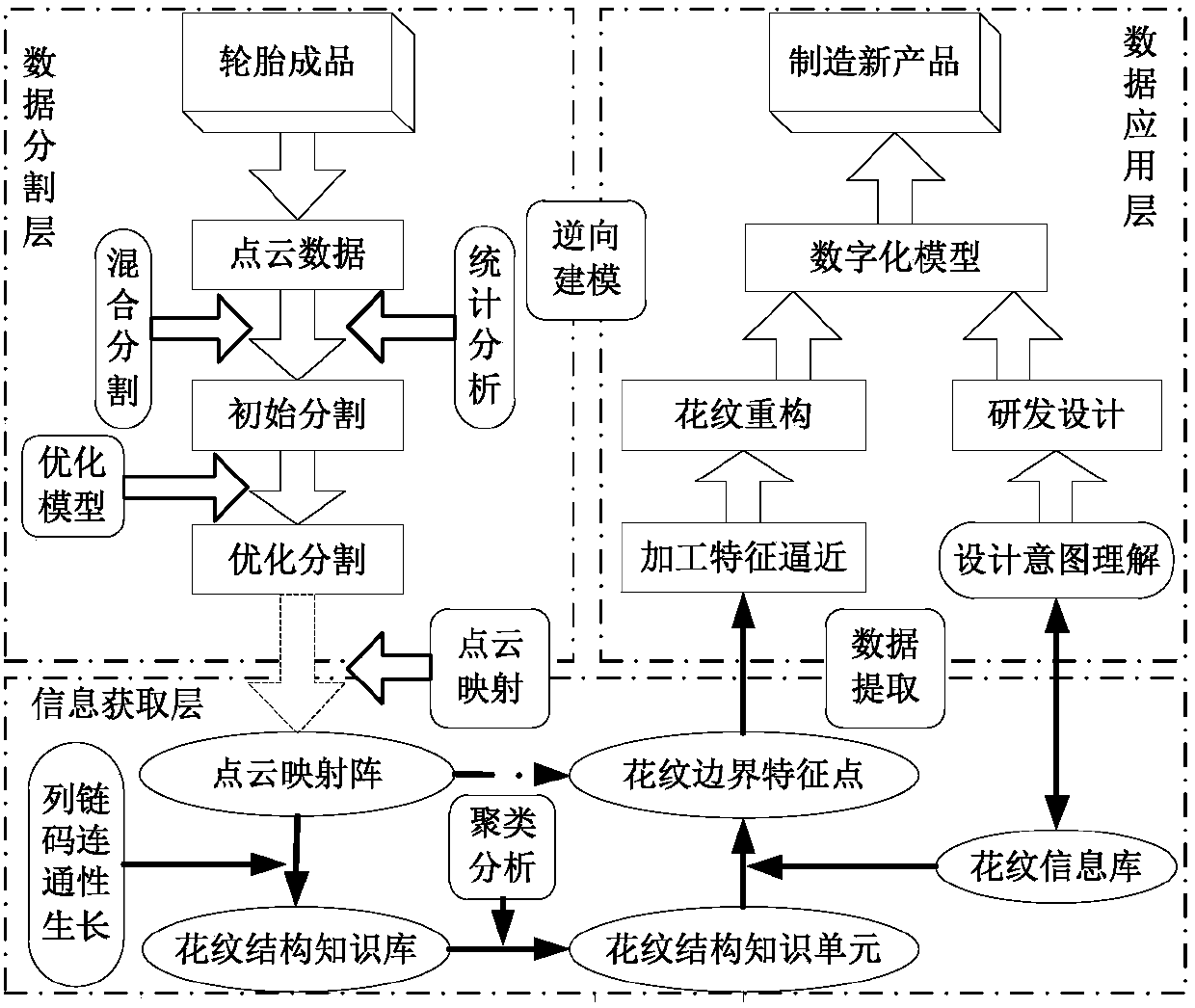

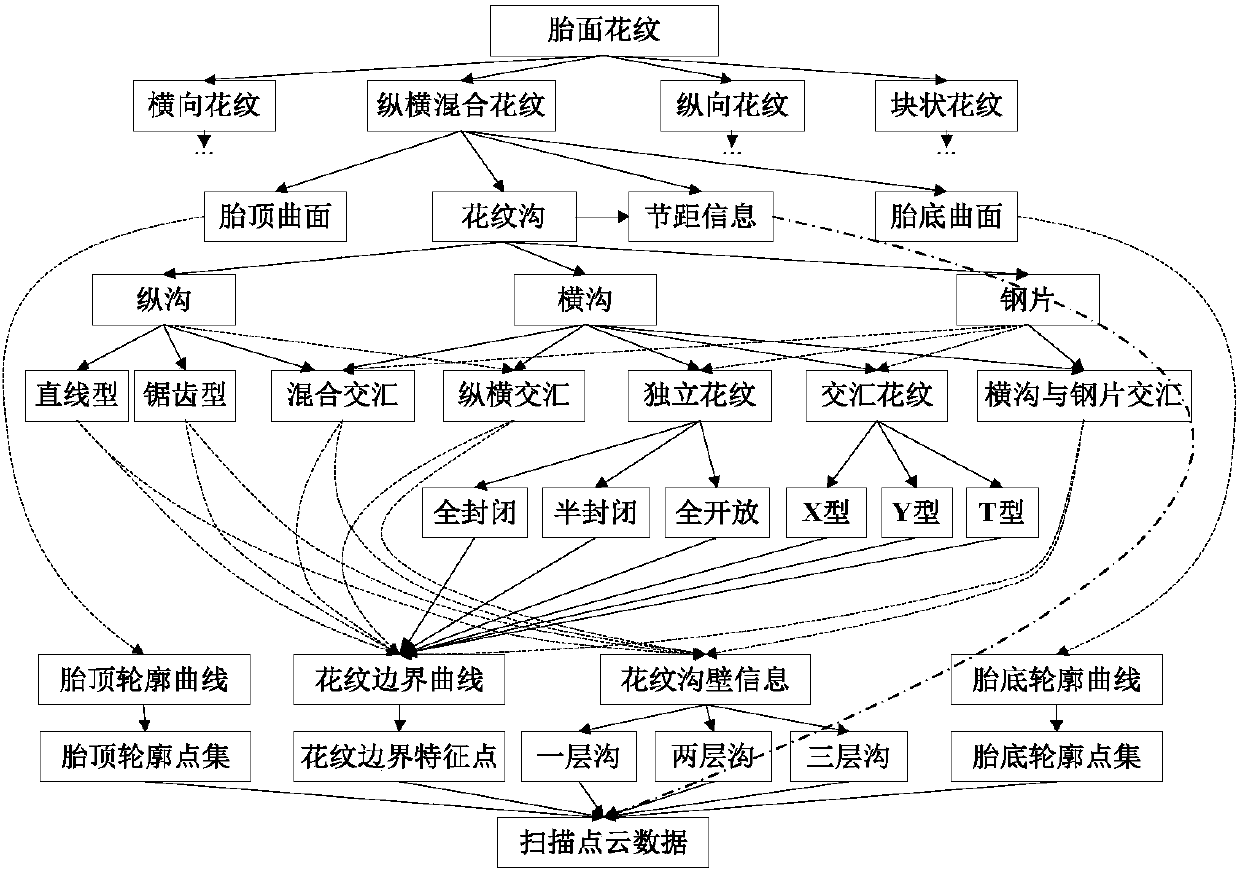

[0056] Such as Figure 1-10 As shown, a reverse modeling method for tire tread structure design parameters includes the following sequential steps:

[0057] S1: Obtain tire point cloud data attributes, analyze the data attributes, and establish theoretical model reconstruction and actual model reconstruction systems;

[0058] In this step, the theoretical model reconstruction process is as follows:

[0059] Step S11: Collect tire point cloud data, and scan the tire three-dimensional point cloud data;

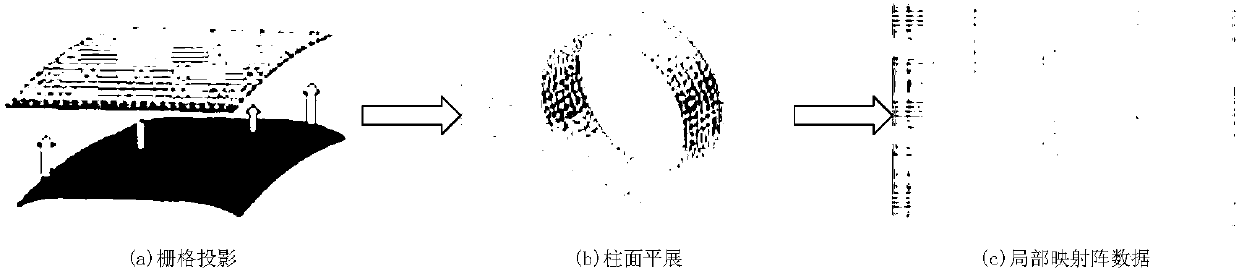

[0060] Step S12: Map the tire tread point cloud into a point cloud mapping matrix;

[0061] Step S13: According to the design theory of the tire outer contour structure parameters and the design criteria of the crown arc and the connecting arc, the method of multi-segment tangent arcs is used to fit the theoretical tire top section curve, and the tire top line is rotated to generate the theoret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com