Catalyst granulation device

A granulation device and catalyst technology, which are applied in the directions of catalyst activation/preparation, physical/chemical process catalyst, die extrusion granulation, etc. Good catalytic effect, beautiful appearance and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

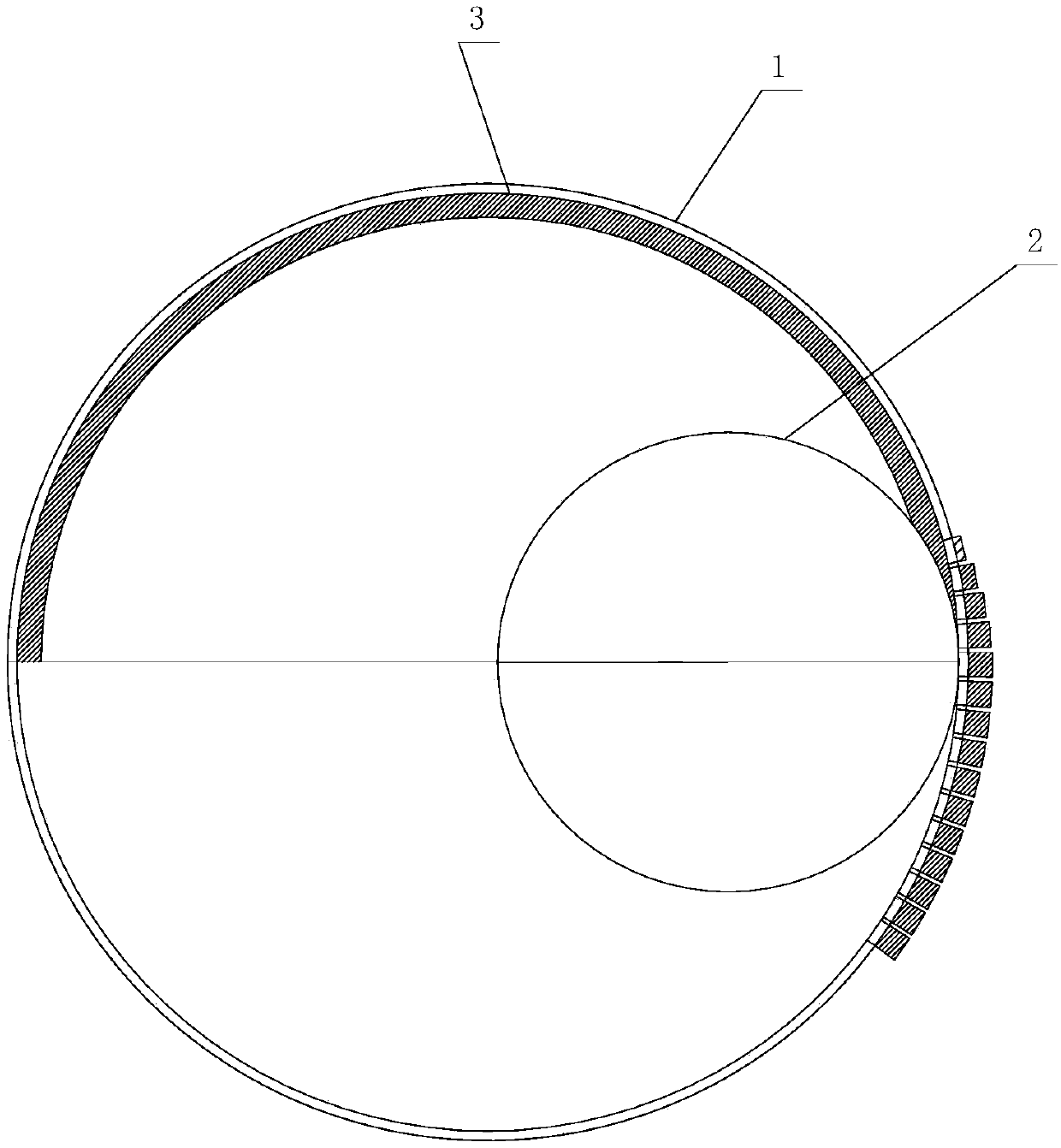

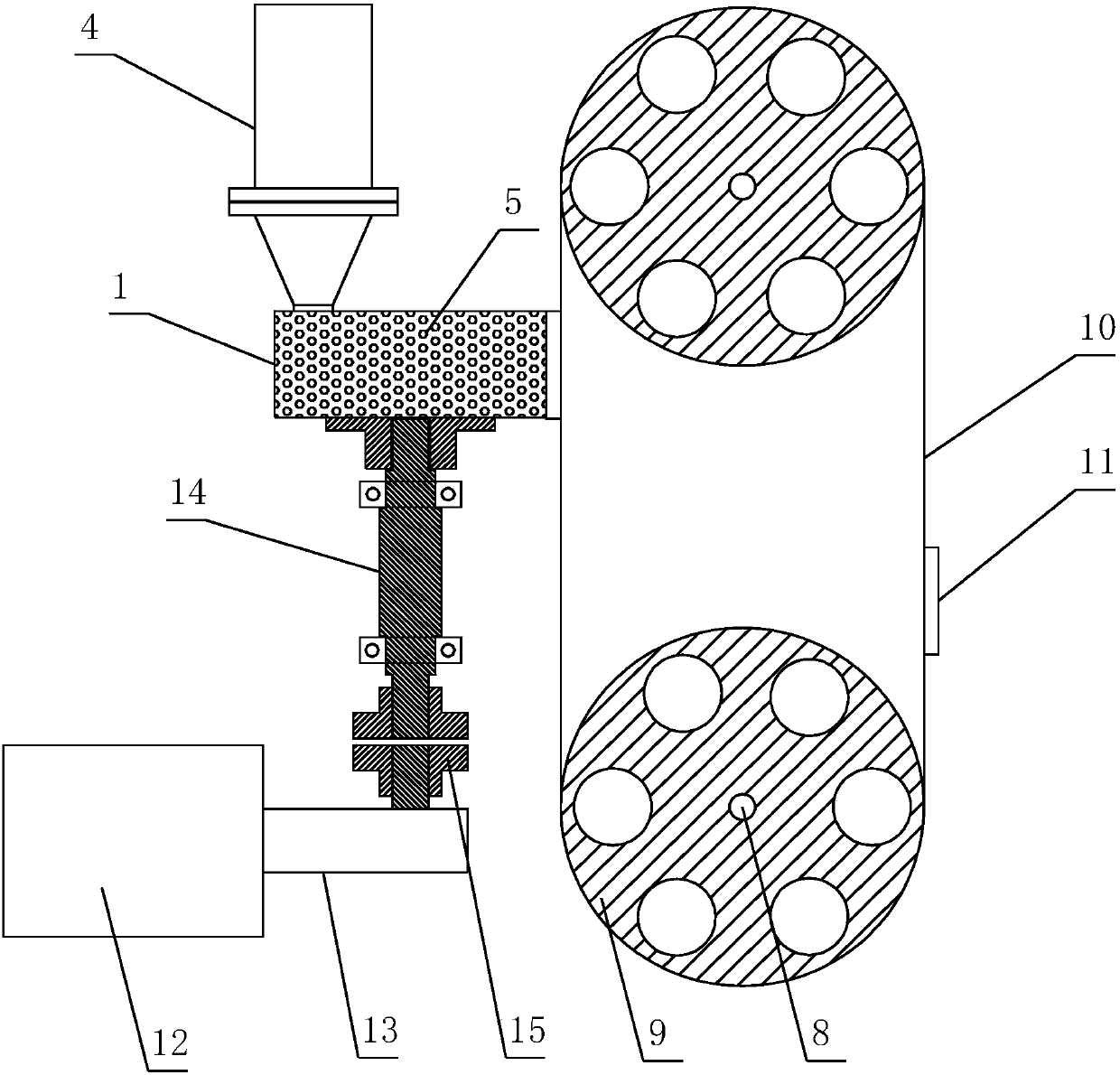

[0020] Such as Figure 1 to Figure 3 As shown, the catalyst granulation device includes a driving motor 12, a cylindrical hole die 1 and a pressure wheel 2 cut inwardly with the cylindrical hole die 1; the inner wall of the cylindrical hole die 1 is provided with a feed channel 3; the feed channel 3 has an inlet and a The outlet; the inlet is connected with a feed hopper 4, and the outlet faces the tangent between the cylindrical hole mold 1 and the pressing wheel 2; the outer wall of the cylindrical hole mold 1 is uniformly provided with a plurality of through holes 5; the inner wall of the through hole 5 is provided with a surface increasing mechanism; The surface increasing mechanism is a tooth pattern; the rotating shaft of the drive motor 12 is connected with a reducer 13 and a transmission shaft 14 in sequence; the free end of the transmission shaft 14 is connected with the pressing wheel 2; the output shaft of the reducer 13 and the transmission shaft 14 are coupled Dev...

Embodiment 2

[0023] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that a solid column 6 is provided in the through hole 5; the side wall of the solid column 6 is connected with a connecting rod 7, and the free end of the connecting rod 7 is connected with the inner wall of the through hole The outer wall of the solid column 6 is provided with a surface-increasing mechanism; the surface-increasing mechanism is a tooth pattern; the surface-increasing mechanism can also be other structures that increase the surface area of the catalyst such as threads, protrusions; the solid column 6 makes the catalyst raw material made hollow , the gear on the inner wall increases the contact area between the catalyst and the reactant, so that the chemical reaction takes less time and achieves a better catalytic effect.

Embodiment 3

[0025] Such as figure 1 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the catalyst granulation device also includes a cutting motor 8 and two transmission wheels 9; a circular saw blade 10 is transmission-connected between the two transmission wheels 9; The saw blade 10 is evenly provided with multiple cutting edges 11; the cutting edge 11 of the circular saw blade 10 is in contact with the outer wall of the cylindrical hole die 1; the rotating shaft of the cutting motor 8 is connected with any transmission wheel 9; the cutting motor 8 drives a transmission wheel 9 to rotate , and then drive another transmission wheel 9 to rotate to make the circular saw blade 10 rotate, and the extruded catalyst is cut off.

[0026] Such as Figure 1 to Figure 3 As shown, when the embodiment 1 to the embodiment 3 are in use, the catalyst raw material is added from the feed hopper 4, and the catalyst raw material enters the feed channel 3, and it e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com