Automatic following, lifting and pneumatic supporting device and laser pipe cutting machine with device

A pneumatic support and follow-up technology, applied to laser welding equipment, tubular objects, applications, etc., can solve the problems that the support cannot adapt to different pipe diameters, it is difficult to add intermediate supports, and it cannot be aligned with the pipe, so as to prevent deflection and reduce Effect of frictional damage and accurate vertical position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

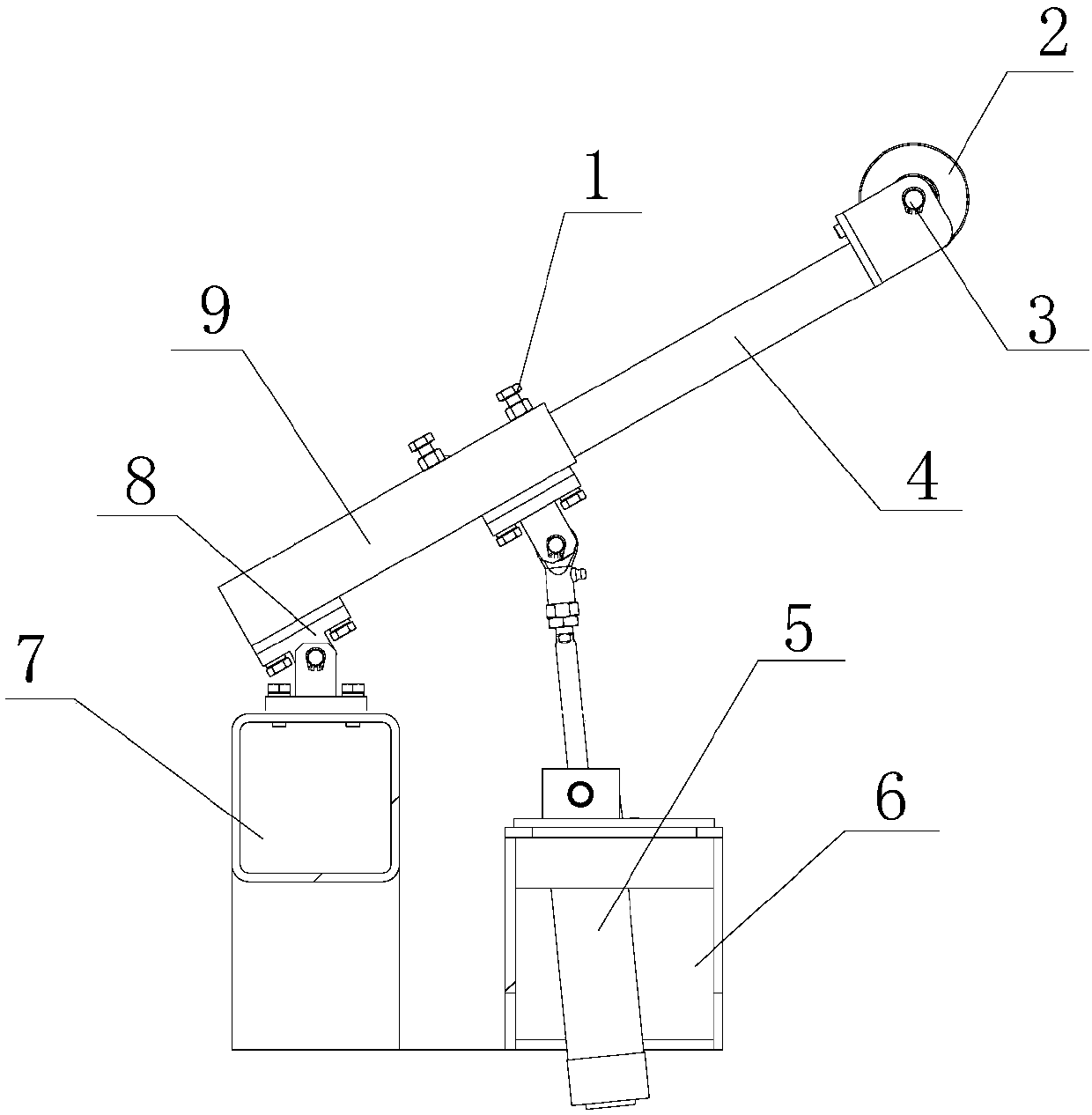

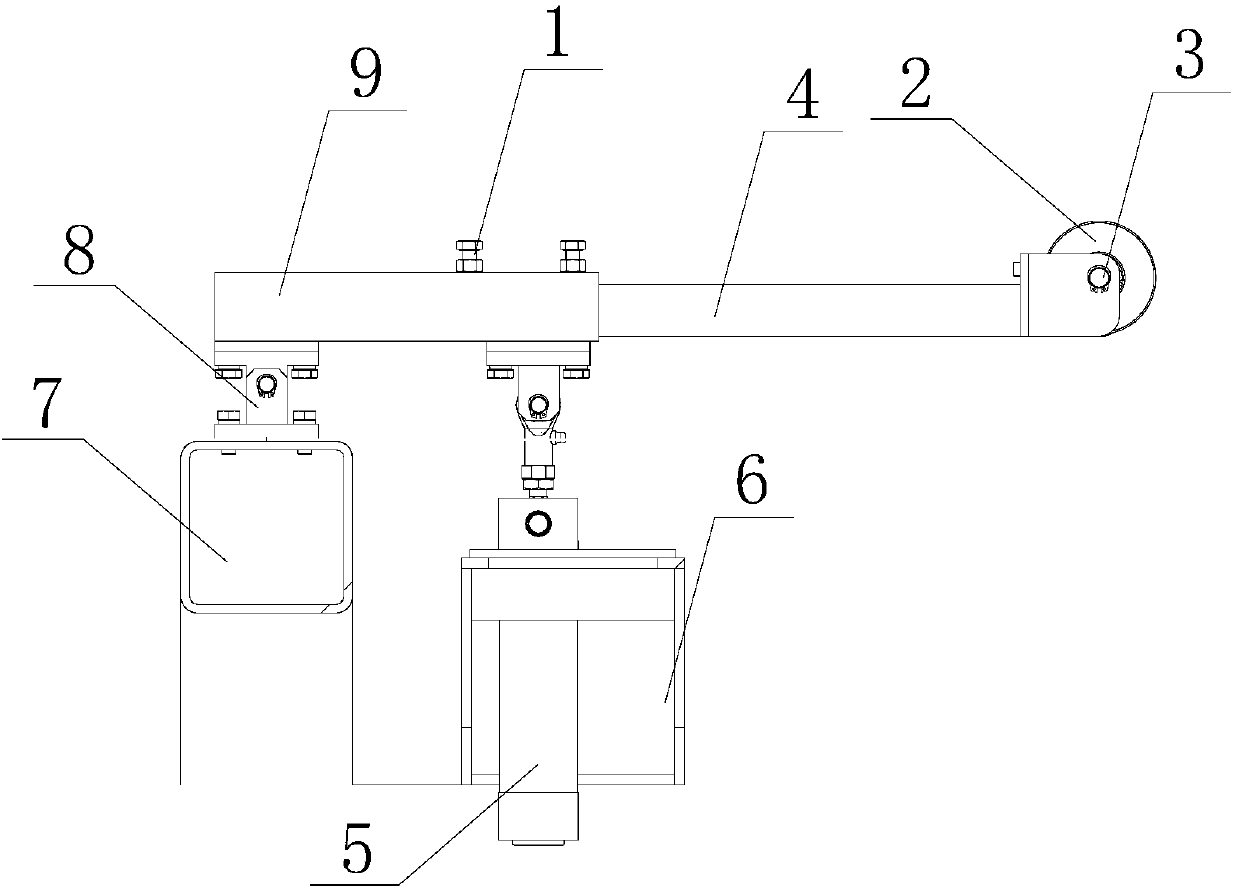

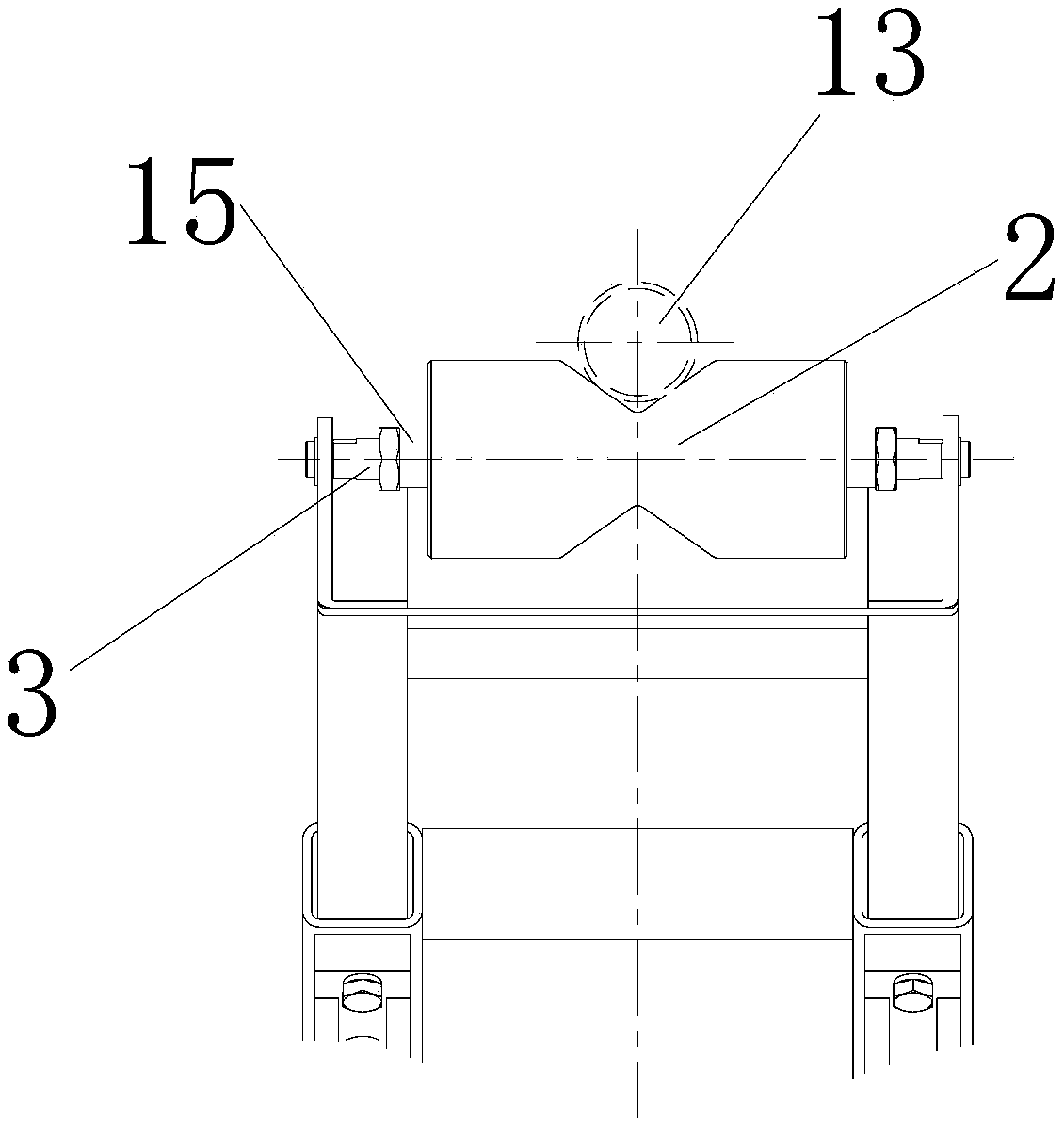

[0031] Such as Figure 1-Figure 3 As shown, an automatic follow-up lifting pneumatic support device includes a cylinder mount 6 and a support arm mount 7. Two parallel connected cylinders 5 are installed on the cylinder mount 6, and the expansion and contraction of the cylinder 5 is controlled by a pneumatic solenoid valve. One end of the sleeve 9 is hinged by a hinge 8 on the support arm mount 7 . The other end of sleeve 9 is hinged with the cylinder shaft of cylinder 5 by hinge 8 .

[0032] A sleeve shaft 4 is sleeved in the sleeve 9, and the front side of the sleeve 9 is provided with a number of openings, and a locking nut 1 is welded coaxially with the openings, and the locking nut 1 is cooperatively connected with a locking screw for tightening the sleeve shaft.

[0033] The sleeve 9, the sleeve shaft 4, the lock nut 1 and the lock screw matched therewith together constitute the support arm assembly, and the support arm assembly can also be replaced by other telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com