Single power source-based variable stiffness flexible joint

A single power source and joint technology, applied in the field of robotics, can solve the problems of difficult joint stiffness linear and precise adjustment, a single stiffness adjustment method, and difficulty in linear and precise adjustment of stiffness, etc., and achieve the effect of large and continuously adjustable stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

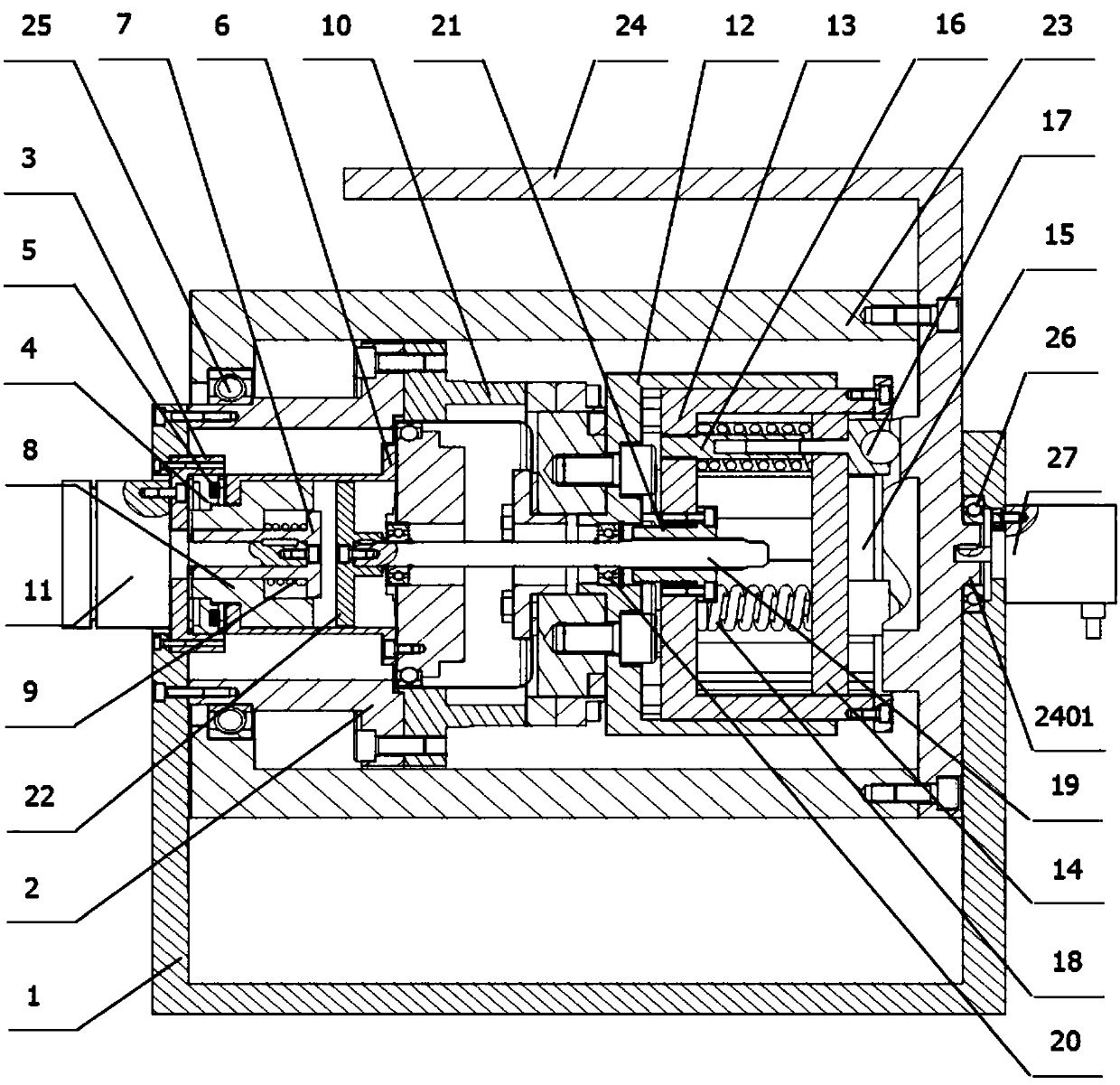

[0051] In this embodiment, the variable stiffness flexible joint based on a single power source includes a joint drive end, a stiffness adjustment mechanism, and a joint output end; the joint drive end is used to provide the torque required for joint drive and stiffness adjustment; the joint output end is connected to the The joint load is connected to drive the load to move; the two ends of the stiffness adjustment mechanism are rigidly connected to the joint drive end and the joint output end respectively, and are used to adjust the connection stiffness between the joint drive end and the joint output end, and output the joint drive end The torque is transmitted to the output end of the joint to realize the stiffness adjustment and flexible output of the joint.

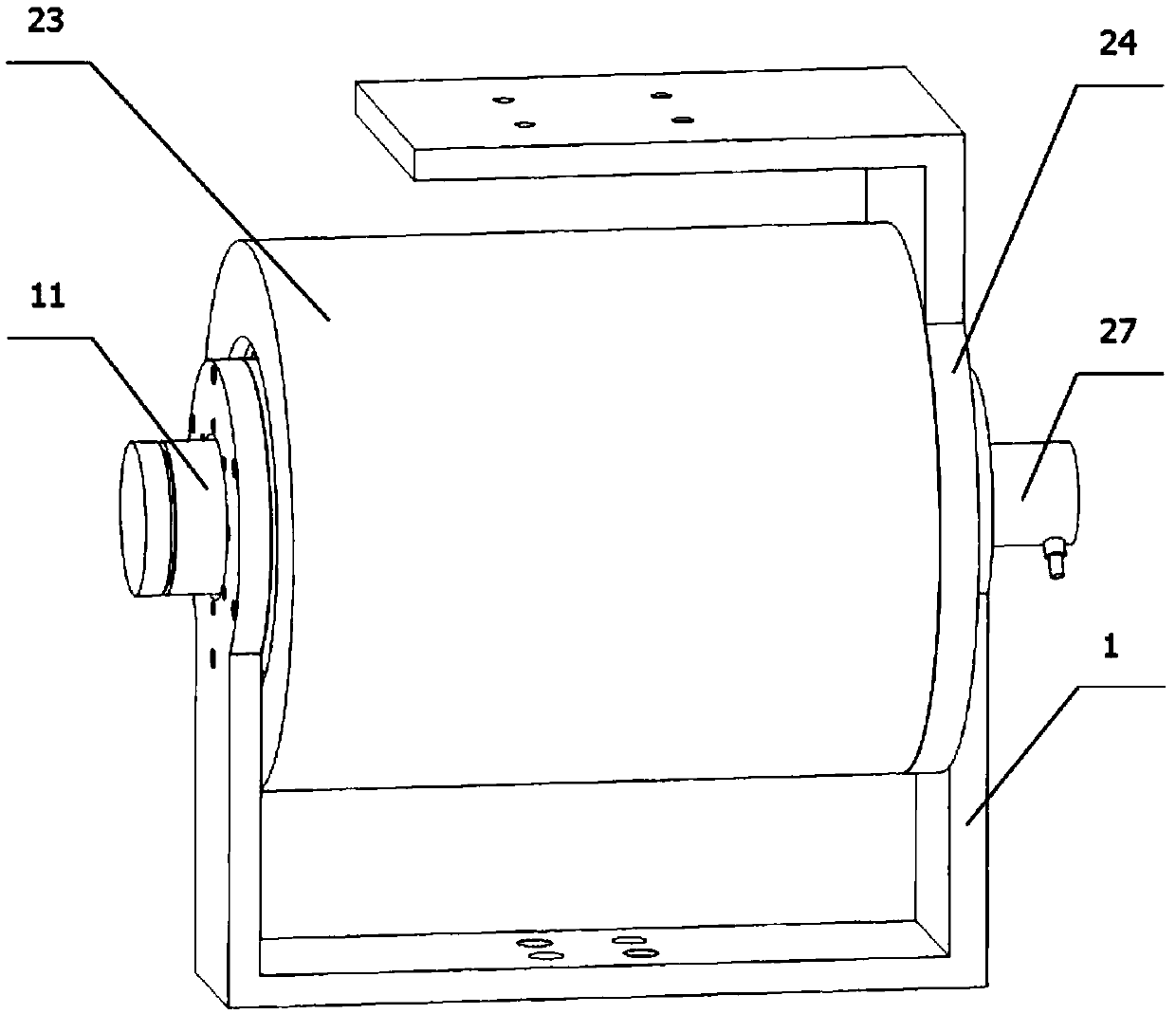

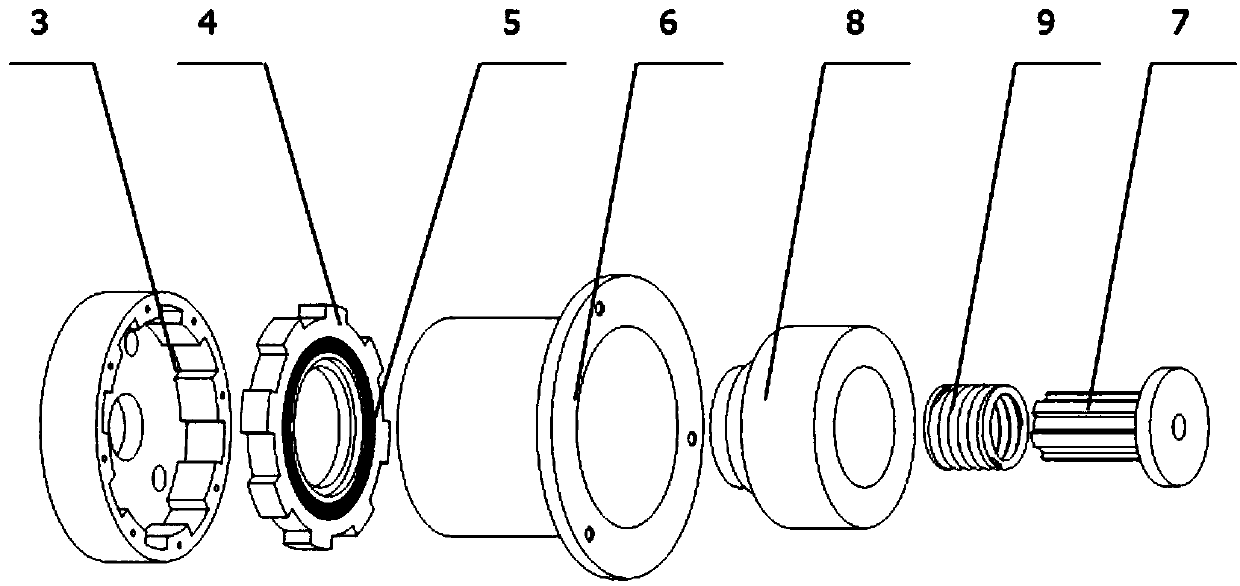

[0052] The joint drive end includes a joint support 1, a reducer support 2, an interlocking clutch structure, a harmonic reducer 10, and a joint drive motor 11; the joint support 1 (see Figure 5 ) is a U-shaped str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com