Dry ice cleaning system and method applied to electronic module assembly process

An electronic module, dry ice cleaning technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of limited cleaning ability of ultrasonic cleaning process, inability to wash off metal powder, damage to module products, etc., and achieve convenient movement. Action, reduce floor space, reduce the effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

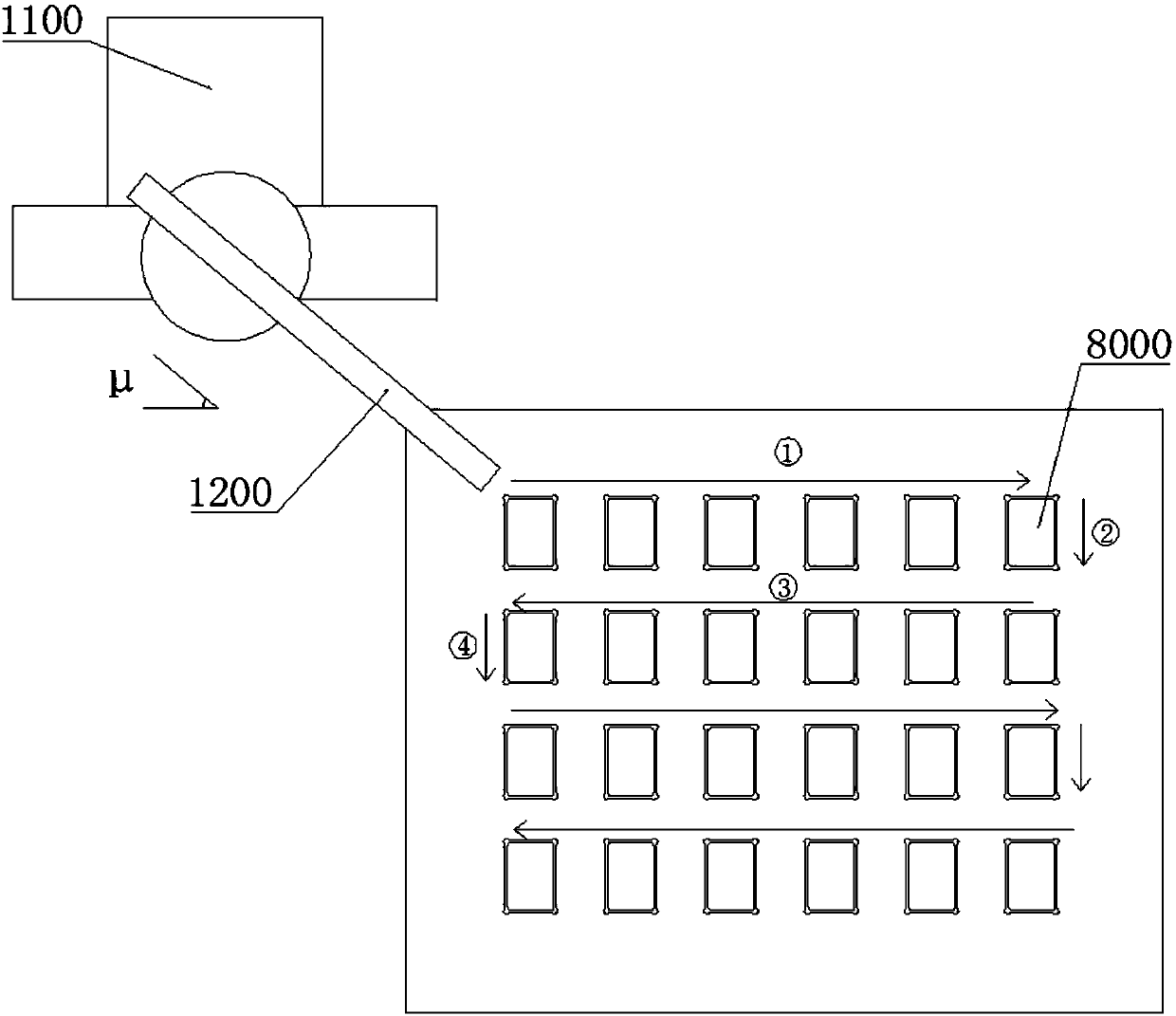

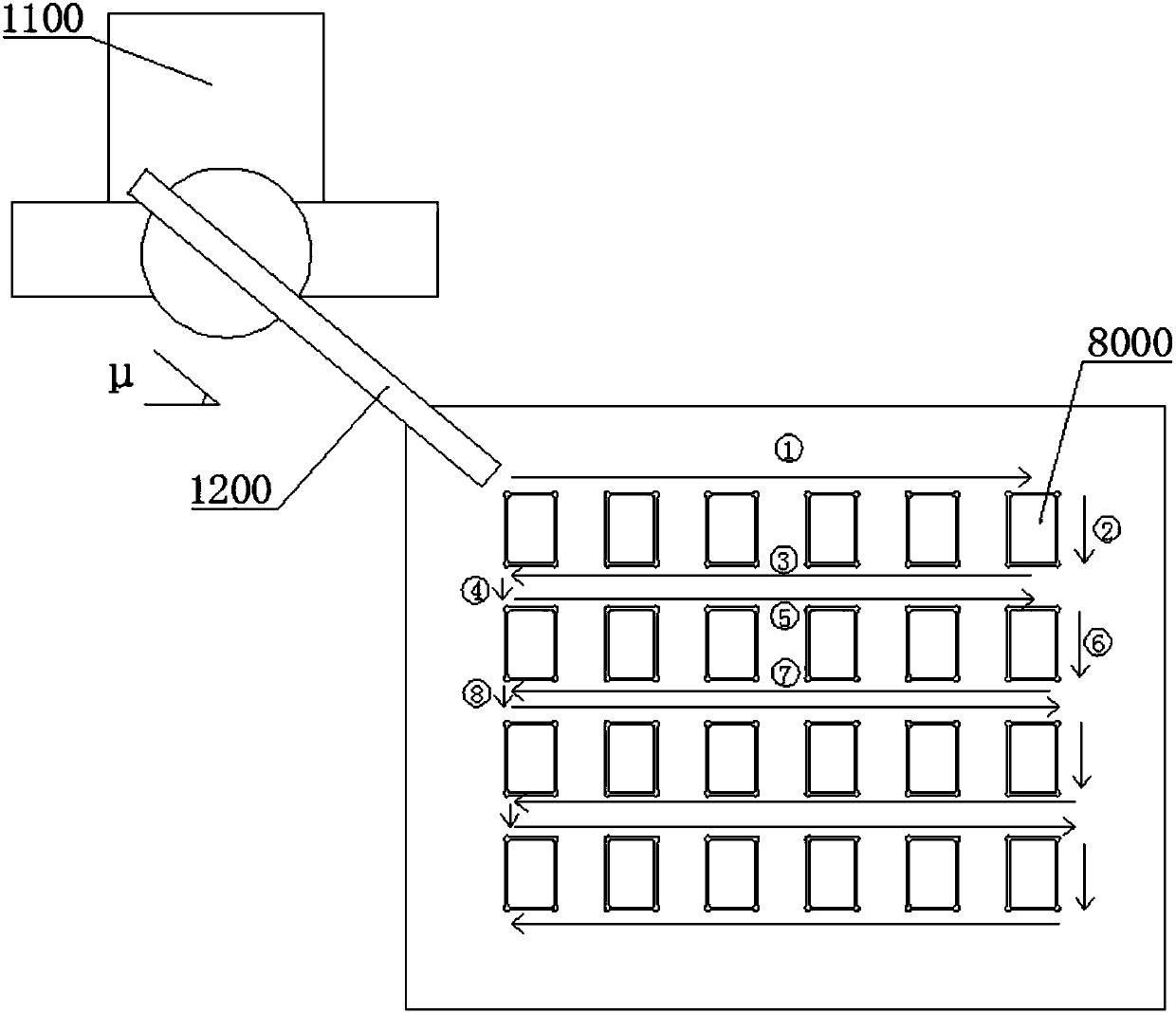

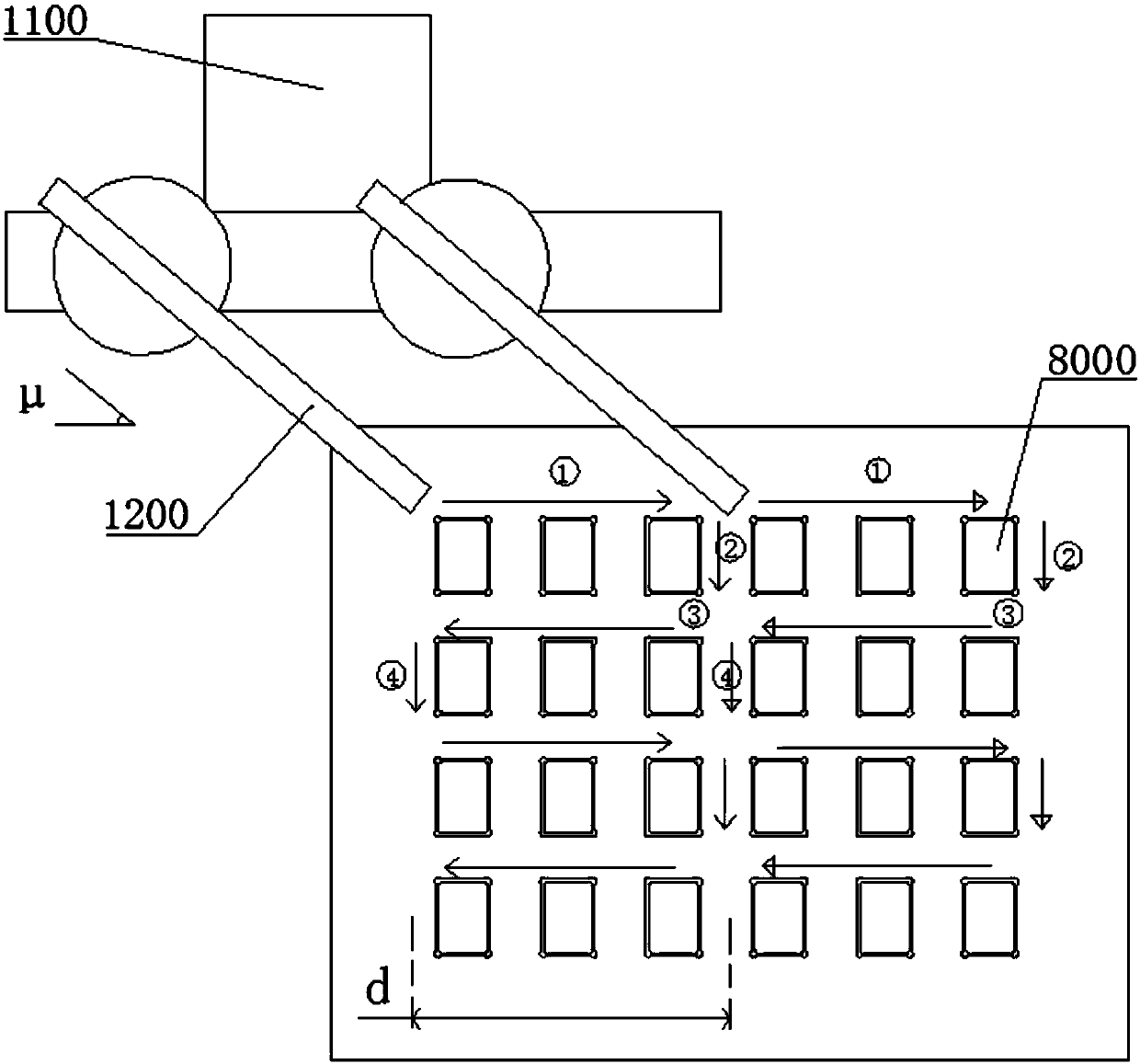

[0090] Such as Figure 5 As shown, this embodiment discloses a dry ice cleaning system applied in the assembly process of electronic modules, including: an ice breaking mechanism 1000, a spray pipeline, a mechanical arm 1100, a cleaning base 1300 and a nozzle 1200. The nozzle 1200 is arranged towards the electronic module 8000 on the cleaning base 1300, and the view in this direction cannot show the specific structure of the nozzle 1200 installed on the mechanical arm 1100.

[0091] In order to better characterize the relative positional relationship between the nozzle and the electronic module, Figure 1-a , 1-b , 2-a, 2-b In four figures, the nozzle is rotated 90° to be parallel to the bottom surface of the cleaning base 1300 .

[0092] Such as Figure 1-a and Figure 1-b As shown, several electronic modules 8000 are arranged in a parallelogram array and fastened to the cleaning base 1300. Generally, the cross-sections of the electronic modules are polygonal shapes compose...

Embodiment 2

[0100] On the basis of Example 1, as Figure 6 , Figure 7 as well as Figure 8 As shown, the cleaning base 1300 is a box-shaped structure with an upper end face open, Figure 6 is the overall structure diagram of the box-like structure, Figure 7 Shown is a schematic cross-sectional structure diagram of the boxed structure, an annular gap 1350 is formed between the parallelogram array arranged by the electronic module 8000 and the side wall of the cleaning base 1300; the dry ice cleaning system of the electronic module also includes a dust filter ( not shown in the figure);

[0101] Such as Figure 6 As shown, the side wall of the cleaning base 1300 is provided with a first air hole 1360, a second air hole and a third air hole 1361, and the second air hole is located between the first air hole 1360 and the third air hole 1361, wherein the first air hole The second air hole faces the electronic module 8000, the first air hole 1360 and the third air hole 1361 face the annu...

Embodiment 3

[0103] On the basis of Example 2, such as image 3 As shown, the dry ice blasting system of the electronic module also includes a carrier 2000 for transferring the electronic module 8000; the parallelogram array on the carrier 2000 is arranged with mounting holes 2100 for the electronic module 8000, Figure 4 shows the detailed structure of the installation hole 2100, the installation hole 2100 includes a top-down platform section 2110 and a through-hole section 2120; wherein, the cross-sectional area of the platform section 2110 is larger than the cross-sectional area of the through-hole section 2120, and in A stepped surface 2111 is formed at the junction with the through hole section 2120 , and the electronic module 8000 is placed on the stepped surface 2111 . Generally, the outer contour of the pallet section 2110 is similar to that of the electronic module 8000 to limit it.

[0104] Such as Figure 7 , Figure 8 as well as Figure 9 As shown, the cleaning base 130...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com