Thick-wall pipe narrow slope SAW automatic welding process and welding machine head

A process method and automatic welding technology, applied in welding equipment, manufacturing tools, welding rod characteristics, etc., can solve problems affecting welding quality and efficiency, improve welding efficiency, improve welding quality and efficiency, and reduce the amount of weld metal filling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to deepen understanding of the present invention, below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0024] The present embodiment provides a narrow-groove SAW automatic welding process for thick-walled pipes, including the following steps:

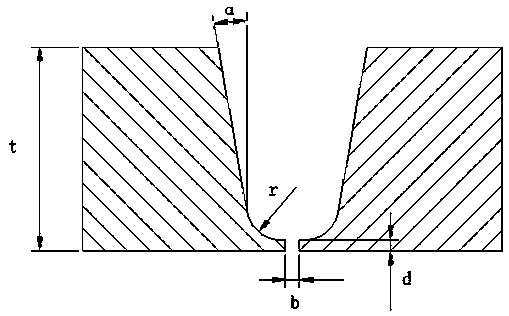

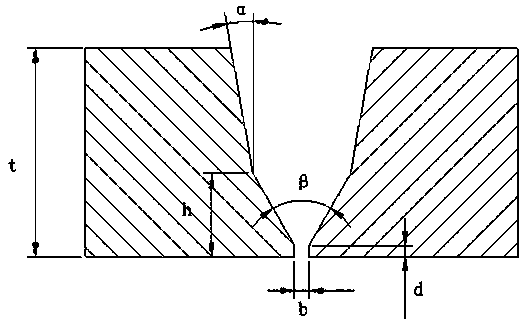

[0025] ①Start with thick-walled pipes, select the research range of wall thickness from 22 to 60mm, and formulate groove specifications for thick-walled pipe fittings based on different standards (such as ASME, national standard or European standard, etc.) for double-V grooves and U-shaped grooves The form and size of the narrow bevel;

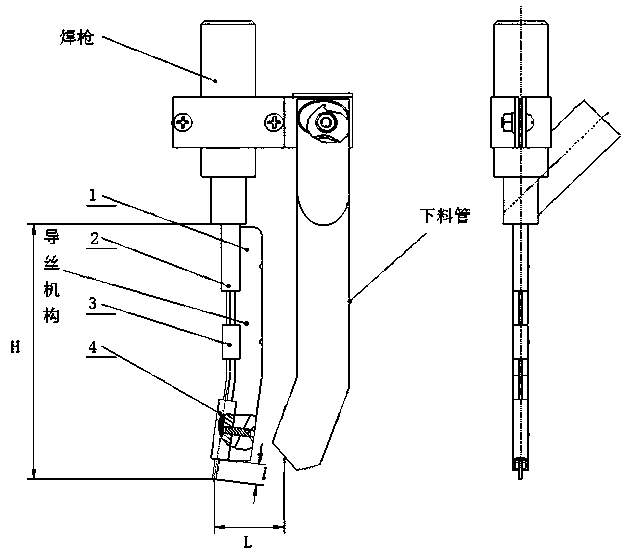

[0026] ②According to the proposed form and size of the narrow groove, design the automatic welding equipment thick-walled pipe narrow groove SAW welding head;

[0027] ③Cut off the pipe fittings to be welded by mechanical processing, bevel the pipe fittings according to the proposed form and size, and derust, degr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com