Plate automatic feeding device

A technology of automatic feeding and plate parts, applied in the direction of grinding/polishing safety device, grinding feed movement, grinding machine tool parts, etc., can solve the problem of affecting grinding quality and equipment accuracy, large consumption of sandpaper, and production efficiency Low-level problems, to achieve the effect of uniform consumption of sandpaper, low renovation cost, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

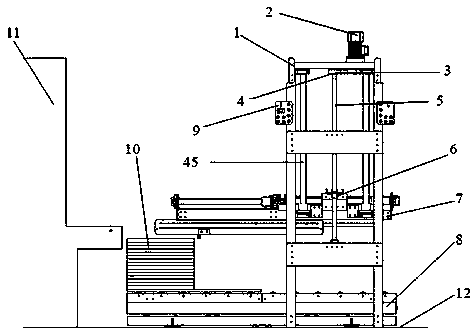

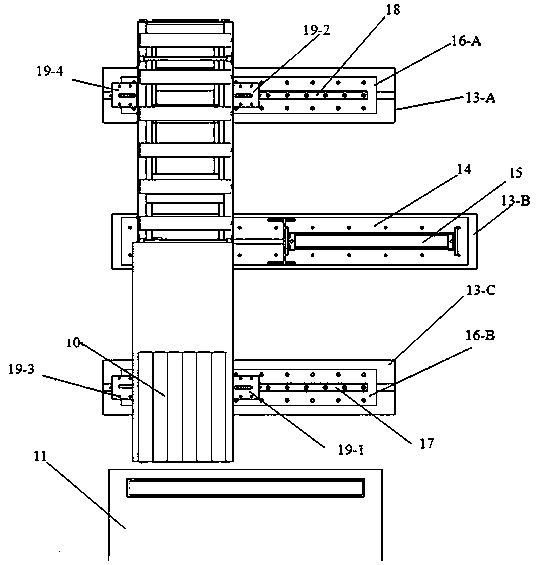

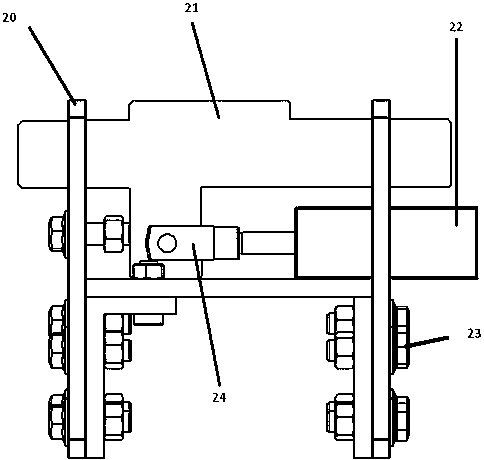

[0025] The automatic board feeding device has a structure including a frame 1, a lifting drive unit of the pushing mechanism, a pushing mechanism unit 7, a lifting and swinging mechanism of the plate; wherein, the lifting driving unit of the pushing mechanism includes a lifting motor 2 and a timing belt 3 , synchronous wheel 4, screw mandrel 5; lifting motor 2 is at the top of frame 1, the motor shaft of lifting motor 2 is connected with synchronous wheel 4 through synchronous belt 3, synchronous wheel 4 is at the upper end of screw mandrel 5, and screw mandrel 5 is vertical It is directly fixed on the side of the frame 1, the screw mandrel 5 is connected with the pushing mechanism unit 7 through the screw nut 6, and the plate lifting and swing mechanism is at the bottom of the frame 1.

[0026] Each of the four corners of the frame 1 has a column, and each column is fixed with a linear guide rail 45. The linear guide rail 45 is used as a lifting guide optical axis that limits ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com