Thicknessing machine for furniture machining

A planer, furniture technology, applied in the direction of planer, processing machines for manufacturing flat surfaces, wood processing appliances, etc., can solve the problems of difficult angle adjustment, waste of materials, unstable cutting tools, etc., to achieve the planing depth Easy to control, simple construction process, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

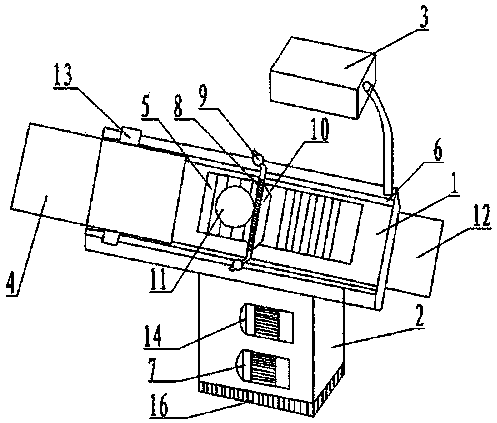

[0012] refer to figure 1 , a planer for furniture processing according to the present invention comprises a support frame 2, the support frame 2 is made of cast iron, a workbench 1 is arranged above the support frame 2, and two parallel guide rails are arranged on the upper surface of the workbench 1 6. The guide rail 6 is provided with a planer sheet workpiece 4, and the planer sheet workpiece 4 moves horizontally along the guide rail 6. A planer friction surface 5 is provided in the middle of the surface of the workbench 1, and a rolling bar is arranged on it. The planer friction surface 5 is provided with a planer cutter 8, the planer cutter 8 is provided with a sheath, the planer cutter 8 is provided with a planer cutter, the planer shaft and the planer reinforcement 10, and the planer cutter 8 is connected There is a planer motor 14, and the planer tool 8 is provided with a planer depth adjustment hole 9. The planer depth adjustment hole 9 can well adjust the planing dept...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap