Gantry tank immersion type production line overturning jig structure

A production line and tank immersion technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve problems such as workpiece defects, blind hole air cannot be completely exhausted, and working fluid corrodes workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

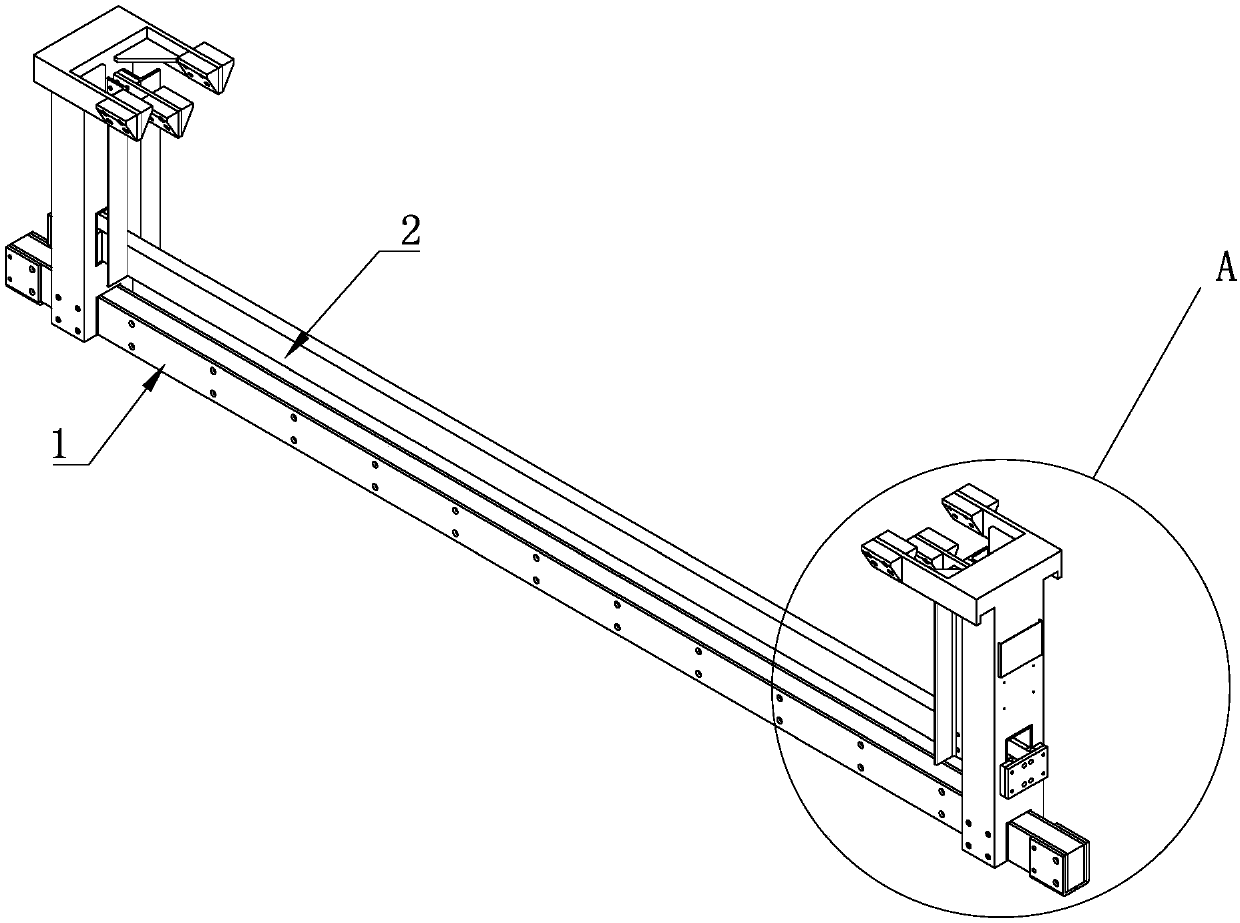

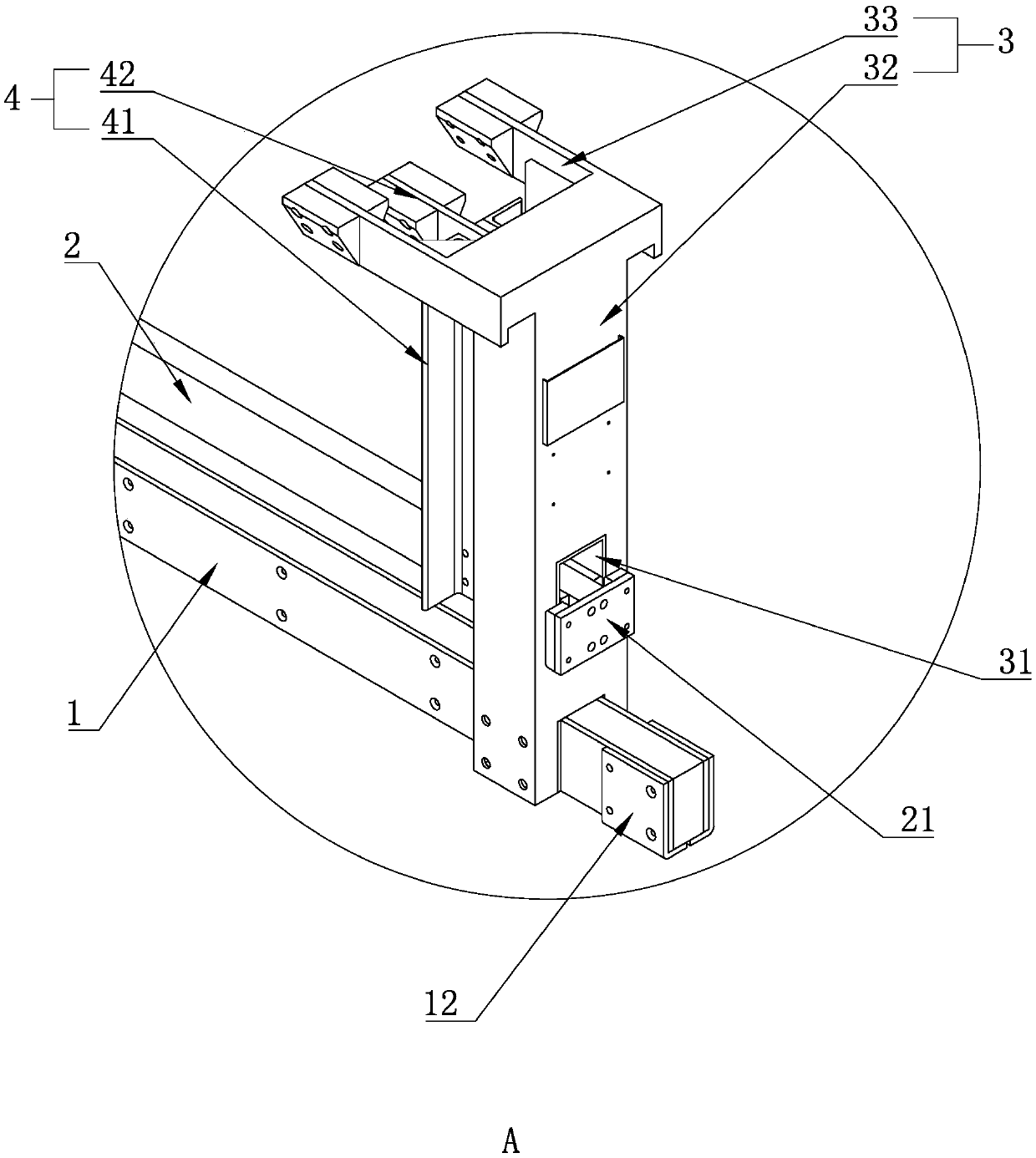

[0034] A flip hanger structure for a gantry tank-immersed production line, including a driving frame and a flying bus arranged on the driving frame. The flying bus includes a main bus 1 and an auxiliary bus 2 connected to both ends of the main bus 1 to drive the main bus 1 The main bar lifting rod 3 moving in the vertical direction and the auxiliary bar lifting rod 4 connected to the two ends of the auxiliary bar 2 to drive the auxiliary bar 2 to move in the vertical direction. The auxiliary bar limit groove 31 for the horizontal displacement of the bar lifting rod 3, the auxiliary bar limit groove 31 is matched with the end of the auxiliary bar 2, the auxiliary bar limit groove 31 runs through the main bar lifting bar 3, and the auxiliary bar 2 The two ends of the auxiliary bar pass through the limit groove 31 of the auxiliary bar respectively, and the two ends of the auxiliary bar 2 are provided with the limit block 21 that is offset against the outer wall of the main bar lif...

Embodiment 2

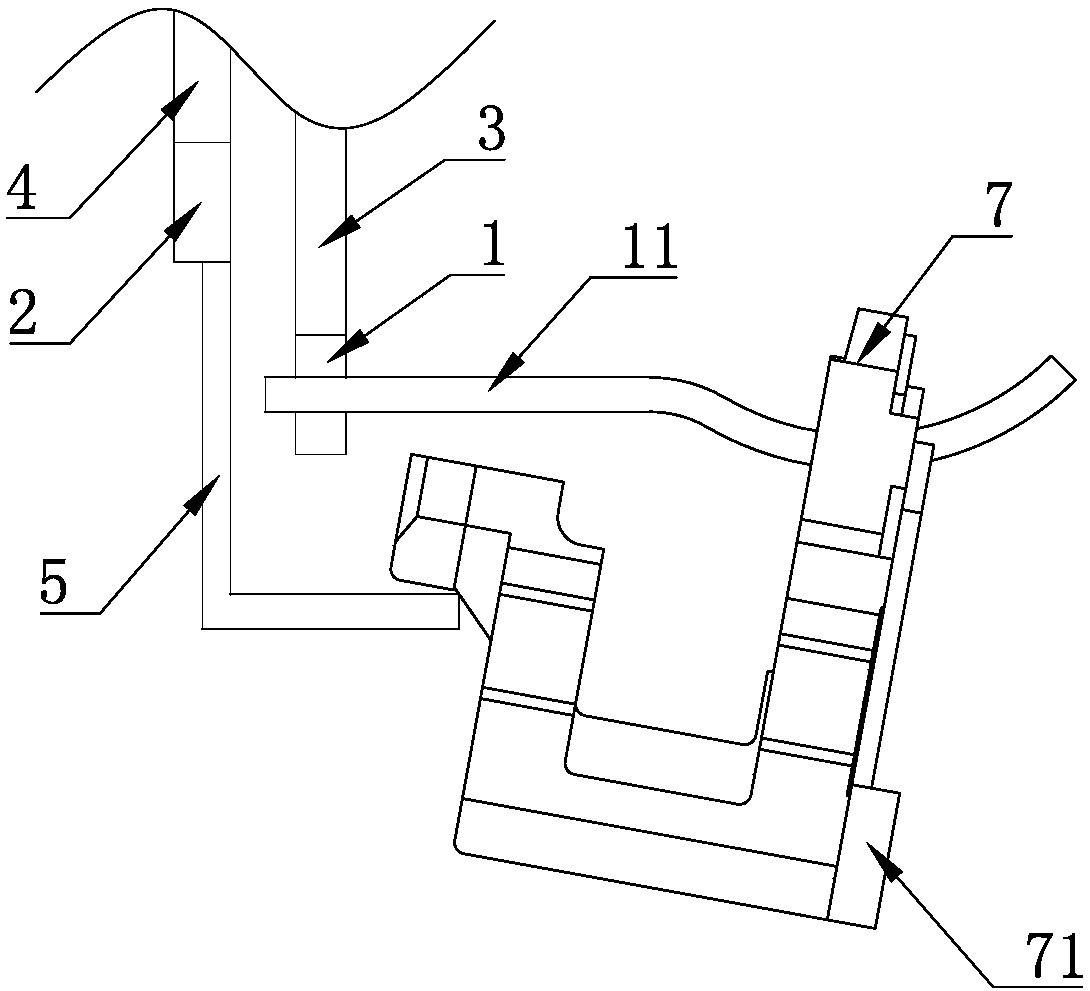

[0040] The difference between this embodiment and the first embodiment is that the turning component is a turning lever 61 that is rotatably connected to the auxiliary bus 2. The turning lever 61 is in an inverted "L" shape and is located above the product 7. There is a limit piece 62 which can be against the top of the turning lever 61 to make the turning lever 61 rotate.

[0041] When the driving lifting hook is lowered, the height of the side of the flip bar 61 close to the auxiliary bus 2 is lowered, so that the flip bar 61 presses down the side of the top of the product 7, so that the product 7 rotates around the hook 11, so that the hook 11 is hung on the hook. The blind hole 71 of the product 7 faces obliquely upward; when the lifting hook of the vehicle is lowered, the height of the side of the turning bar 61 close to the auxiliary bus 2 is raised, and the limit member 62 limits the top of the turning bar 61, so that the turning bar 61 Rotate clockwise around the stopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com