Safety control method of device for preparing ethylene through acetylene hydrogenation

A technology for safety control and ethylene plant, applied in the field of acetylene hydrogenation to ethylene, can solve the problems of lack of control method and no actual control method, and achieve the effect of reducing hydrogen circulation, reducing energy consumption and ensuring reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0012] The safety control method of acetylene hydrogenation ethylene plant of the present invention, its preferred embodiment is:

[0013] Including a hydrogen intake pipeline and an acetylene intake pipeline, the hydrogen intake pipeline is provided with two sets of hydrogen flow meters, a hydrogen shut-off valve and a hydrogen regulating valve, and the acetylene intake pipeline is provided with two sets of acetylene flow meters , a set of acetylene interlock shut-off valve and a set of acetylene regulating valve, also includes a set of PLC control system;

[0014] When the measurement error of the two sets of hydrogen flow meters and / or the two sets of acetylene flow meters exceeds the specified error, an alarm is issued and an interlock is triggered, thereby closing the acetylene interlock shut-off valve and the hydrogen interlock shut-off valve.

[0015] The two sets of acetylene flow meters are used as the measured value of the acetylene flow meter after high selection, a...

specific Embodiment

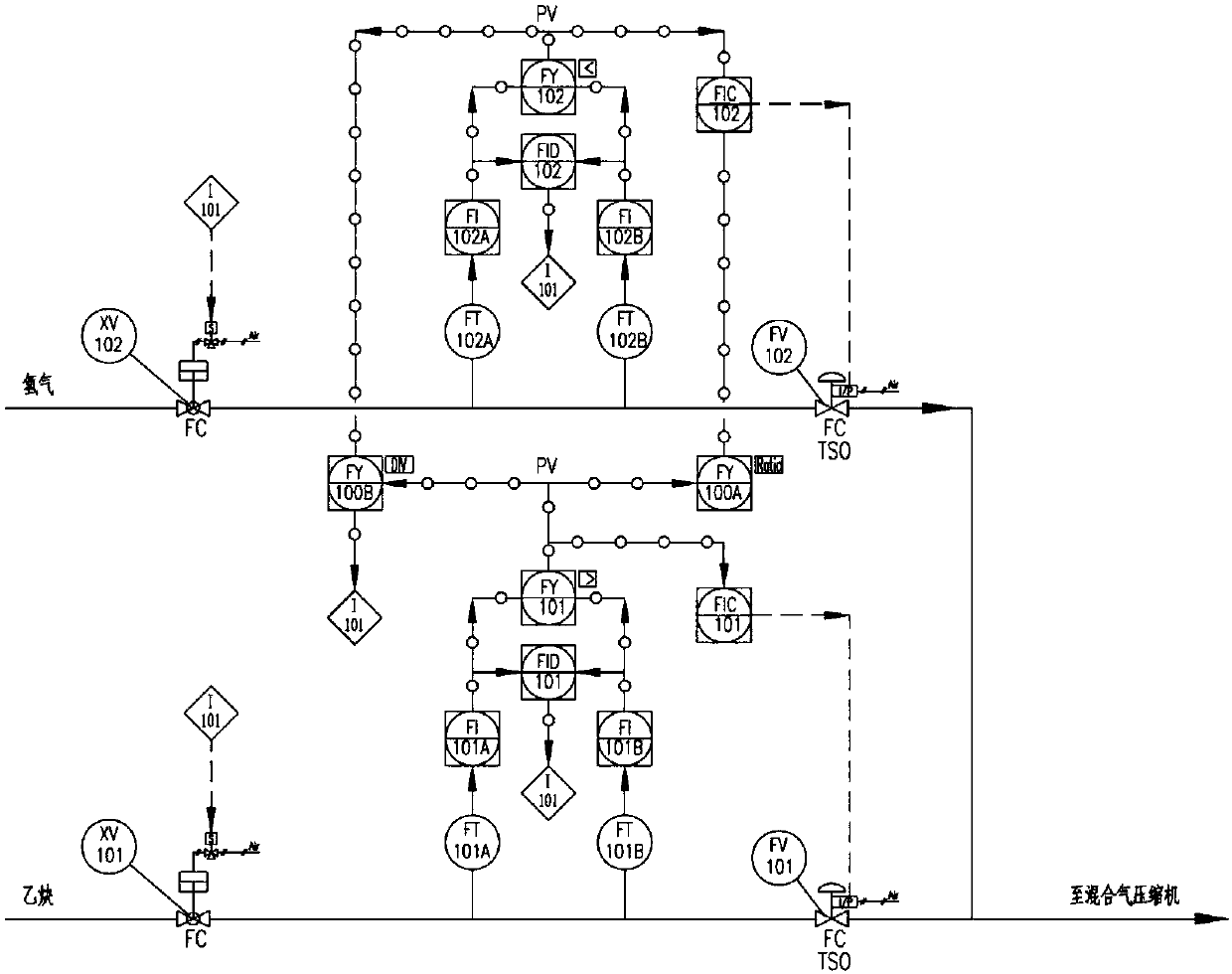

[0020] Such as figure 1 As shown, including two sets of acetylene flow meters (FT-101A / B), two sets of hydrogen flow meters (FI-102A / B), one set of acetylene regulating valves (FV-101), one set of hydrogen regulating valves (FV-102 ), a set of acetylene interlock shut-off valve (XV-101), a set of hydrogen shut-off valve (XV-102) and a set of PLC control system.

[0021] in:

[0022] Two sets of acetylene flow meters, FT-101A and FT-101B, aim to overcome the error of acetylene flow meters and improve the reliability of acetylene measurement. When the measured value of the two sets of meters does not exceed the specified value, the FY-101 high selector , select a higher value as the measured value of the acetylene flow FI-101, and perform single-loop adjustment to control the opening of FV-101 to ensure the stability of the acetylene flow. The set value to control the flow of hydrogen. In order to ensure the safety of the device, a small amount of excess hydrogen is used to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com