Double-layer water-cooled fire grate based on vertical coal-fired boiler

A coal-fired boiler, double-layer water cooling technology, applied in the directions of double-layer grate, grate, combustion method, etc., can solve the problems of low grate hardness and strength, waste of energy, etc., to improve hardness and strength, reduce cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The selected sheet a3 is composed of the following components according to the mass fraction: 6% aluminum, 8.5% silicon, 4% chromium, 20% carbon steel, and the balance is pig iron. The sum of the mass percentages of the above components is 100%.

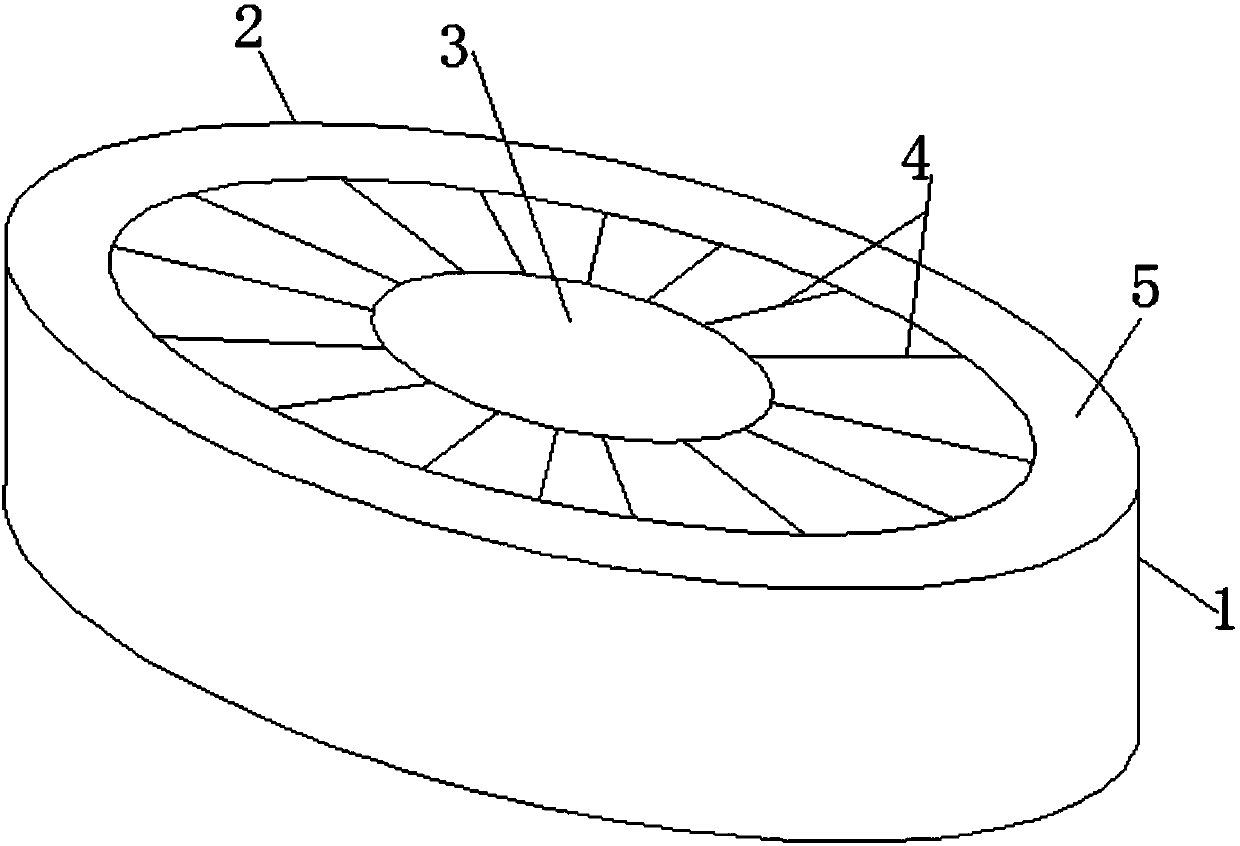

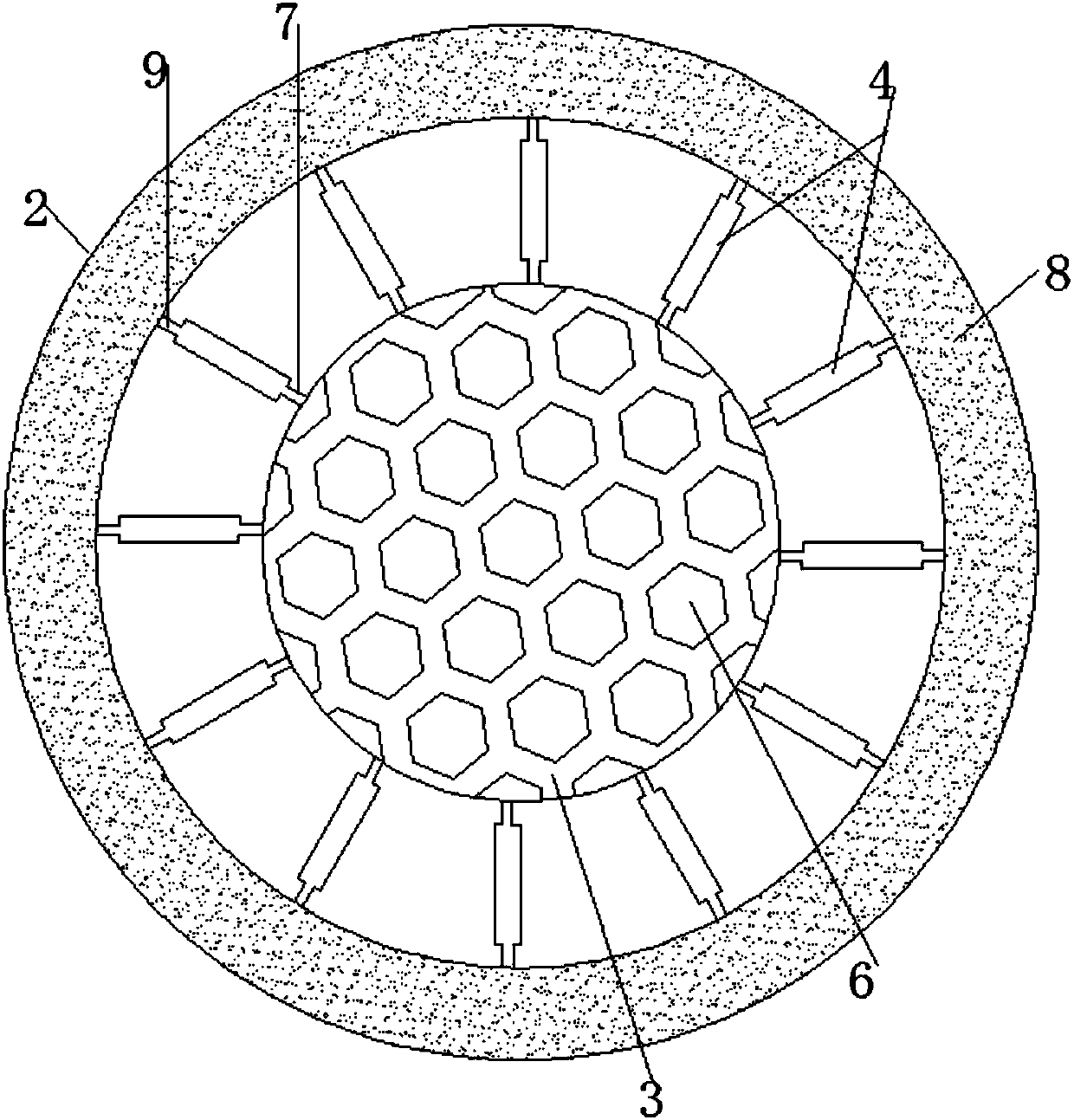

[0029] The double-layer water-cooled fire grate includes a tubular support frame 1, and a group of parallel fire grate pieces 2 are respectively fixed at both ends of the support frame 1. The angle between each fire grate piece 2 and the central axis of the support frame 1 is 30°. The radial direction of the fire grate 2 is sequentially provided with a row a3 and a row b5, a number of water pipes 4 are arranged between the row a3 and the row b5, and along the radial direction of each fire grate 2, a row a3 and a row b5 are sequentially arranged, and the row a3 A water pipe 4 is arranged between the row sheet b5, and the angle between every two adjacent water pipes 4 is 20°. The top of each row sheet b5 is evenly covered with a ...

Embodiment 2

[0031] The selected sheet a3 is composed of the following components according to the mass fraction: 10% aluminum, 12.5% silicon, 8% chromium, 22% carbon steel, and the balance is pig iron. The sum of the mass percentages of the above components is 100%.

[0032] The double-layer water-cooled fire grate includes a tubular support frame 1, and a group of parallel fire grate pieces 2 are respectively fixed at both ends of the support frame 1. The angle between each fire grate piece 2 and the central axis of the support frame 1 is 40°. The radial direction of the fire grate 2 is sequentially provided with a row a3 and a row b5, a number of water pipes 4 are arranged between the row a3 and the row b5, and along the radial direction of each fire grate 2, a row a3 and a row b5 are sequentially arranged, and the row a3 A water pipe 4 is arranged between the row sheet b5, and the angle between every two adjacent water pipes 4 is 35°. The top of each row sheet b5 is evenly covered wit...

Embodiment 3

[0034] The selected sheet a3 is composed of the following components according to the mass fraction: 8% aluminum, 10% silicon, 6% chromium, 21% carbon steel, and the balance is pig iron. The sum of the mass percentages of the above components is 100%.

[0035] The double-layer water-cooled fire grate includes a tubular support frame 1, and a group of parallel fire grate pieces 2 are respectively fixed at both ends of the support frame 1. The angle between each fire grate piece 2 and the central axis of the support frame 1 is 35°. The radial direction of the fire grate 2 is sequentially provided with a row a3 and a row b5, a number of water pipes 4 are arranged between the row a3 and the row b5, and along the radial direction of each fire grate 2, a row a3 and a row b5 are sequentially arranged, and the row a3 A water pipe 4 is arranged between the row sheet b5, and the angle between every two adjacent water pipes 4 is 30°. The top of each row sheet b5 is evenly covered with a s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap