Device and method for measuring size and porosity of object and vacuum air sealing method

An object and volume technology, which is applied in the field of measuring the volume of objects, can solve the problems of unfavorable effects of measured objects or users, affecting measurement accuracy, and large processing capacity of 3D laser scanning data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

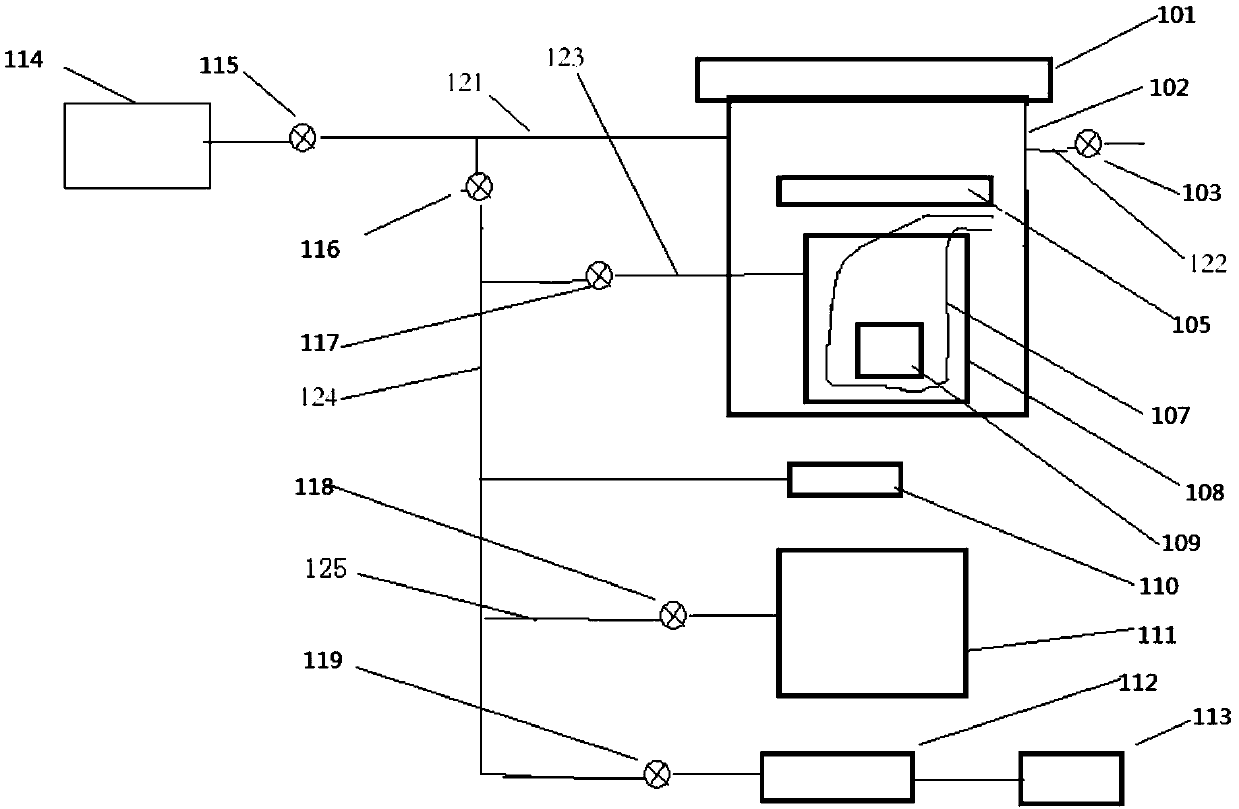

[0069] Refer to attached figure 1 As shown, the device for measuring the volume of an object in the present invention includes a first measuring container, a second measuring container, a vacuum pump 114 , a flow meter 112 , a pressure sensor 110 and an encapsulating air bag 107 .

[0070] The first measuring container includes a first box body 102 and a first cover body 101 sealingly fitted with it. The first box body 102 is provided with a first gas outlet and a first gas inlet, and the first gas outlet passes through a first vacuum tube. 121 is connected with the vacuum pump 114, the first vacuum tube 121 is provided with a first valve 115, the first gas inlet is connected with a second vacuum tube 122, and the second vacuum tube 122 is provided with a second valve 103. Then, when the first valve 115 is opened, the vacuum pump 114 can realize the vacuum in the first measuring container, and when the second valve 103 is opened, the gas can be released in the first measuring ...

Embodiment 2

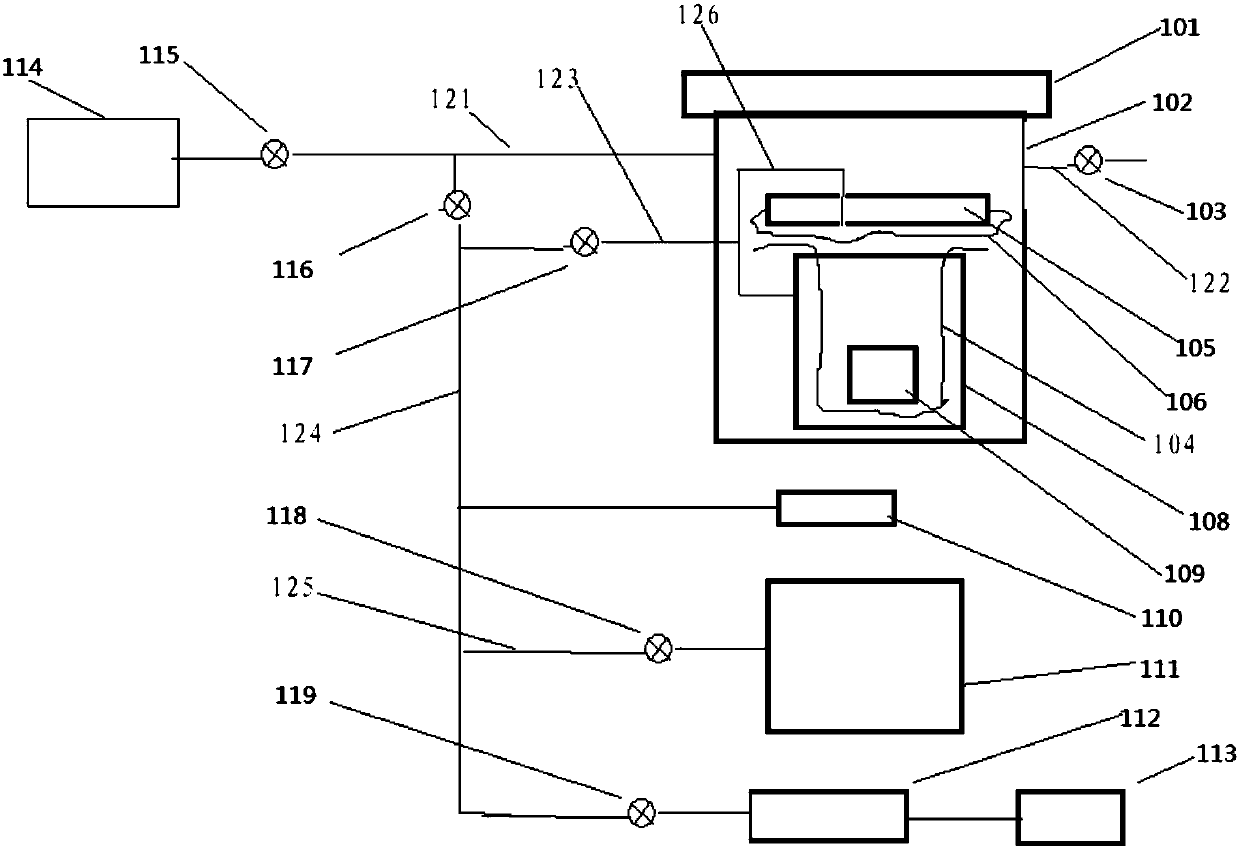

[0077] The difference between the second embodiment and the first embodiment lies in the encapsulation of the air bag, refer to the attached figure 2 As shown, the sealing air bag in this embodiment includes a main body bag 104 and a cover body bag 106. the bottom end of the second cover 105 . The third vacuum tube 123 is also connected to a side tube 126, and the second cover 105 is provided with a second gas through hole, and the other end of the side tube 126 passes through the second gas through hole and connects with the second cover 105 and the second cover 105. If the gap between the cover bags 106 is connected, the side pipe 126 can realize the extraction and filling of the gas between the second cover 105 and the cover bag 106, further ensuring that the first measuring container, the second measuring container and the packaging gas Vacuum in and between bags. The second embodiment is the same as the rest of the first embodiment, and will not be repeated here.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com