Symmetrical mandrel-type optical-fiber hydrophone probe of temperature drift resistance

A fiber optic hydrophone, temperature drift technology, used in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problem of difficulty in ensuring the reliability and accuracy of demodulation results, and the temperature changes of the sensitive arm and the reference arm cannot be synchronized. , the phase difference drift of the two arms, etc., to overcome the influence of environmental temperature changes, improve reliability and measurement accuracy, and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

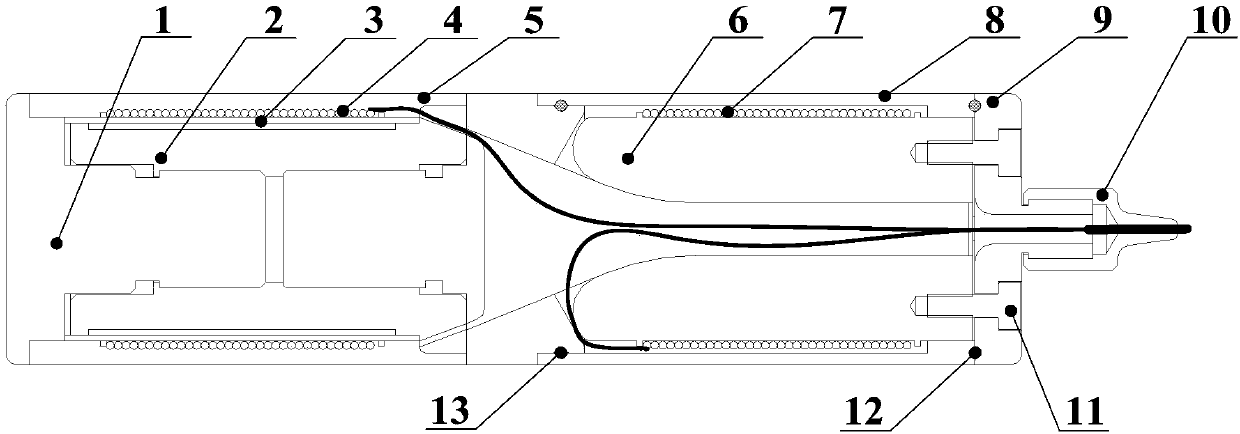

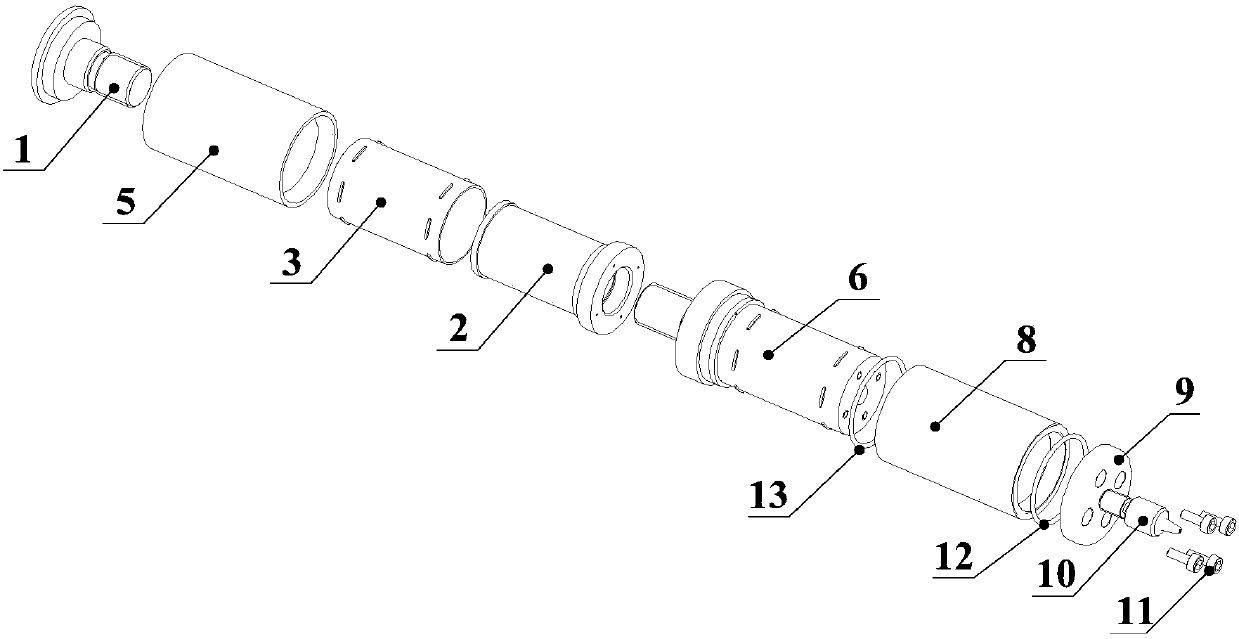

[0036] Such as figure 1 Shown is the assembly diagram of the symmetrical mandrel type fiber optic hydrophone probe of the present invention which is resistant to temperature drift; figure 2 Shown is the explosion diagram of the symmetrical mandrel-type fiber optic hydrophone probe resistant to temperature drift of the present invention. It can be seen from the figure that the fiber optic hydrophone probe of the present invention includes a sensitive component, a reference component and an optical fiber watertight joint 10, wherein the sensitive component includes a sensitive part End cover 1, sensitive part skeleton 2, sensitive wall 3, sensitive optical fiber 4 and sensitizing coating 5, reference assembly includes reference part skeleton 6, reference optical fiber 7, reference sleeve 8, reference part end cap 9, fastening screw 11. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com