Ultraviolet LED light source system for ink curing

A technology of LED light source and LED lamp beads, applied in optics, optomechanical equipment, microlithography exposure equipment, etc., can solve the problems of unsatisfactory curing effect, low energy utilization rate, narrow spectrum, etc., to improve the curing effect of ink, Balanced light intensity and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific examples.

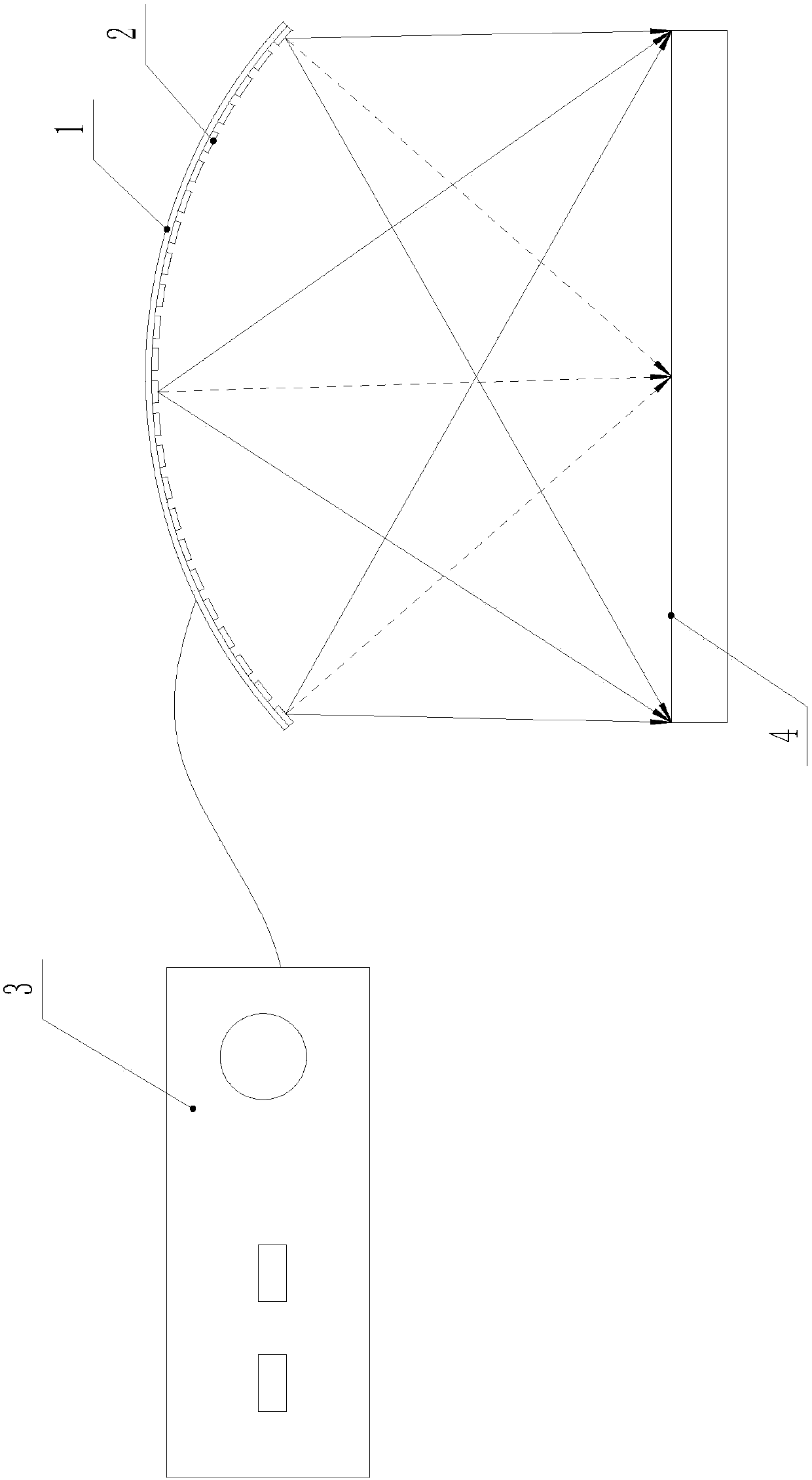

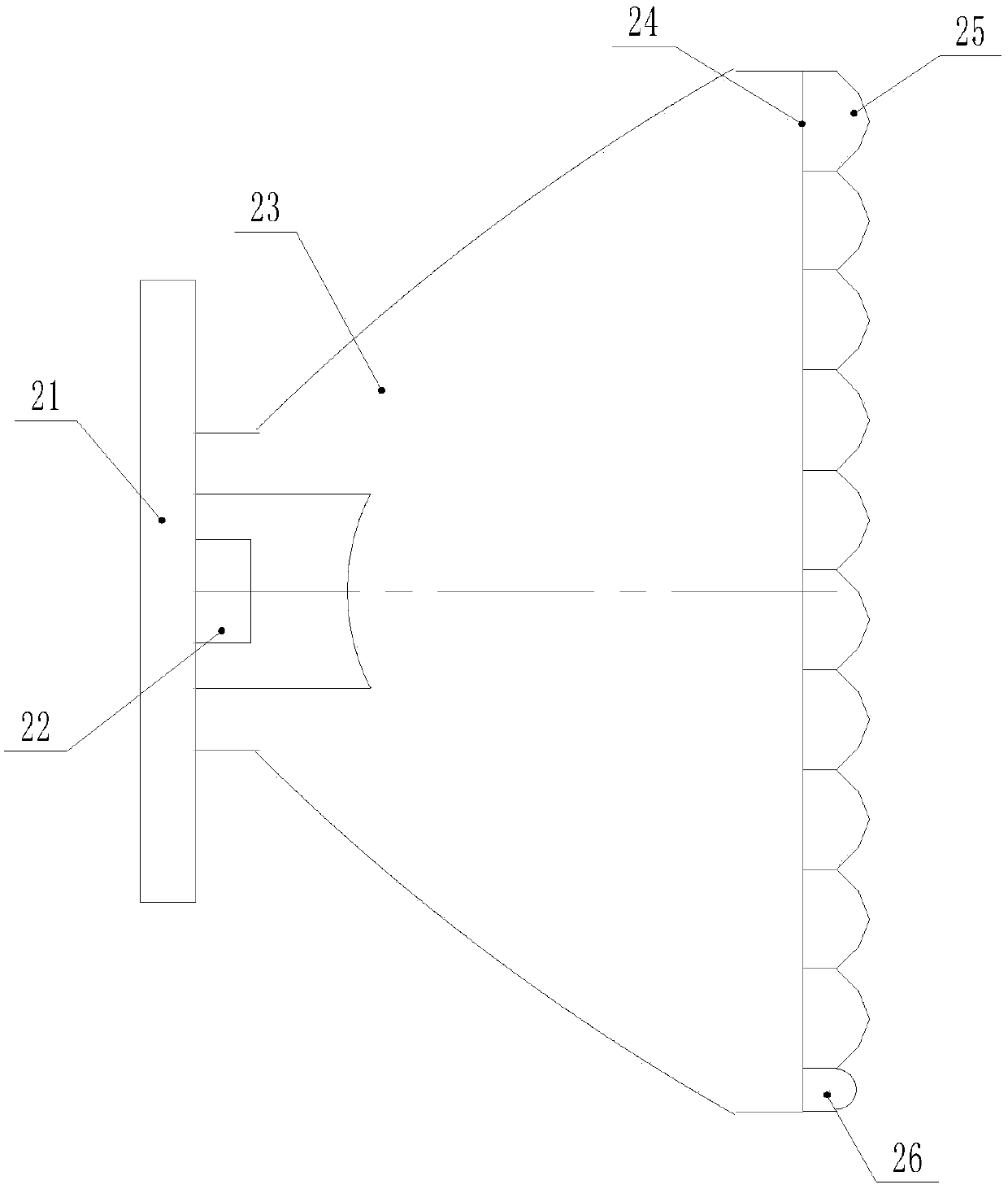

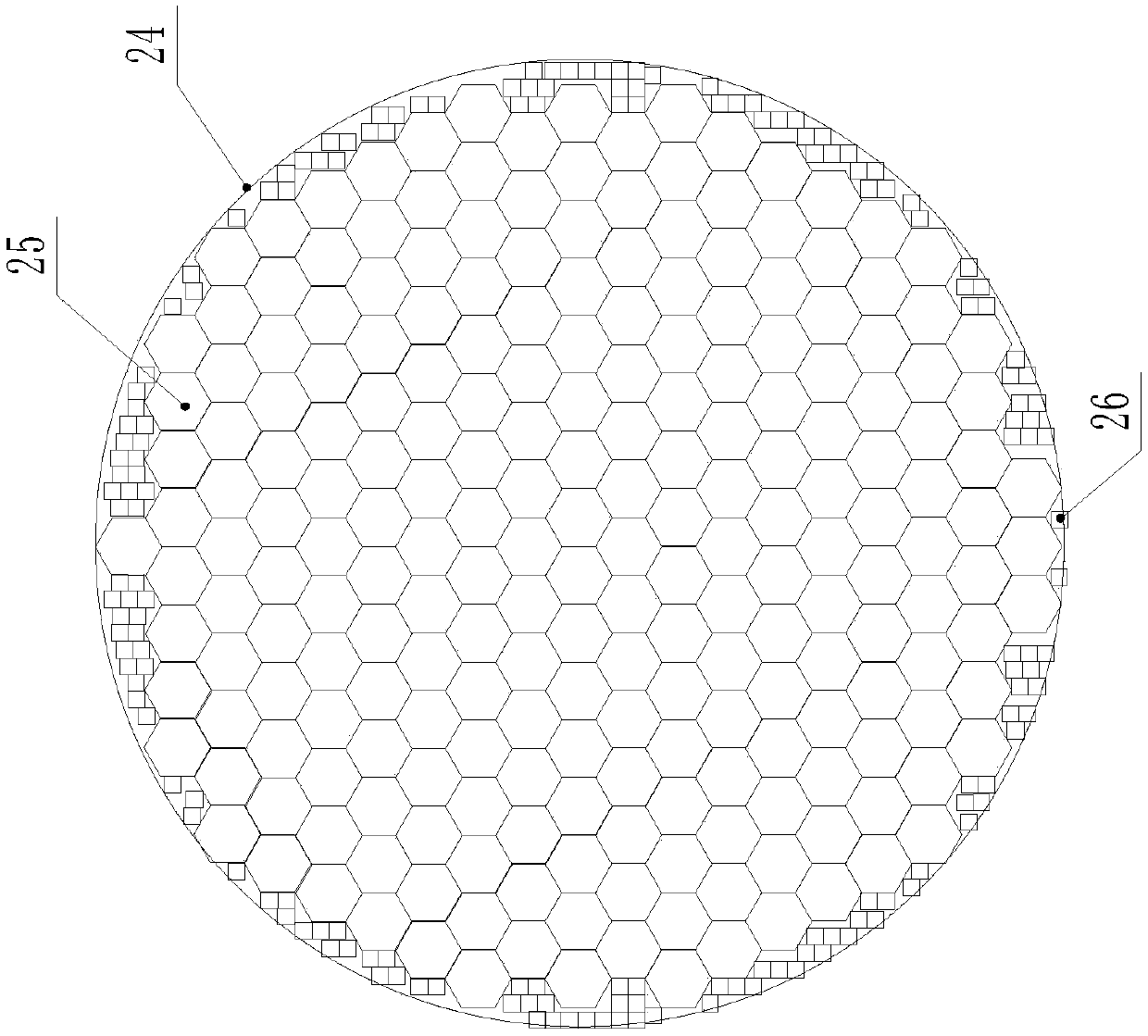

[0022] Such as Figure 1 to Figure 5 As shown, an ultraviolet LED light source system for ink curing includes an LED power supply control box 3 and an ultraviolet LED light source light output head electrically connected to the power control box 3. The ultraviolet LED light source light output head includes a spherical fixed plate 1, and the An ultraviolet LED array is fixed on the inner side of the spherical surface fixing plate 1, and the center of the irradiated target surface 4 coincides with the spherical center of the spherical surface fixing plate 1, and the ultraviolet LED array includes a plurality of LED lamps emitting ultraviolet light of different wavelengths Bead assembly 2, each LED lamp bead assembly 2 is alternately arranged on the spherical fixed plate 1, each LED lamp bead assembly 2 includes a substrate 21 and an LED lamp bead 22 fixed on the substrate 21, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com