Method for detecting hot spot of solar cell

A technology of solar cells and detection methods, applied in the field of solar cells, can solve the problems of limited number of components, inability to realize solar cells, one-sided results, etc., and achieve the effects of small external influence, strong operability, and simple implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

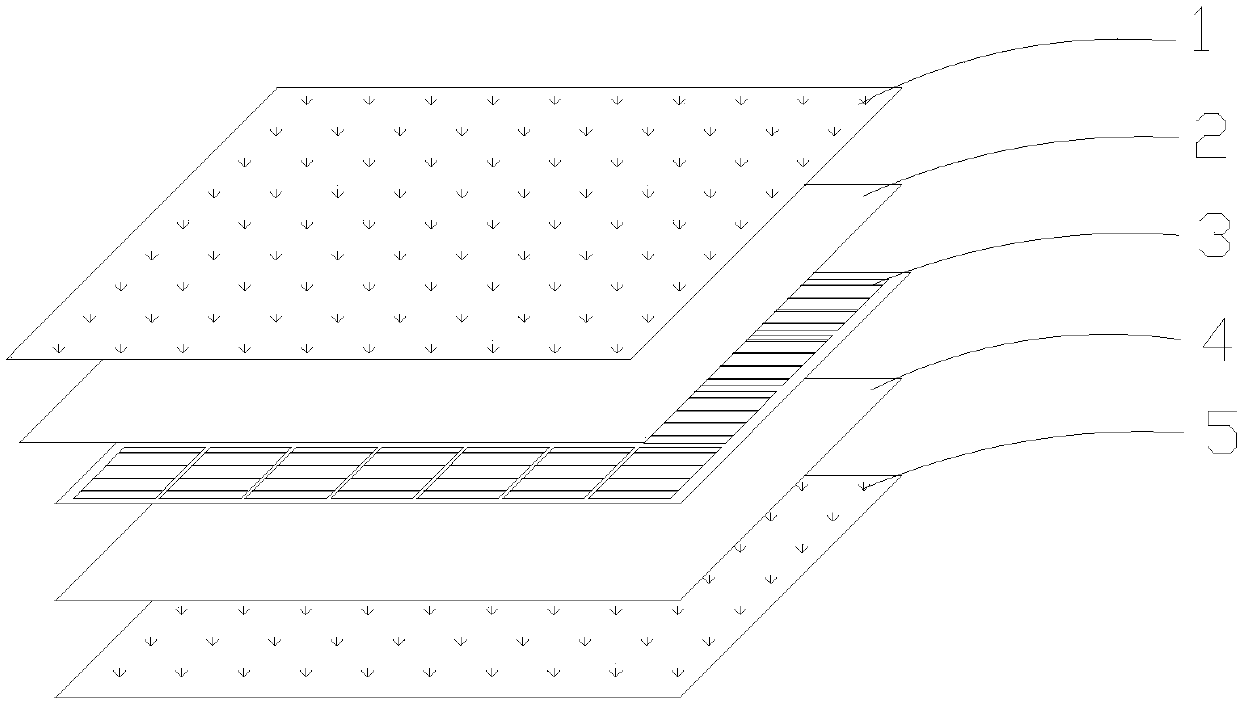

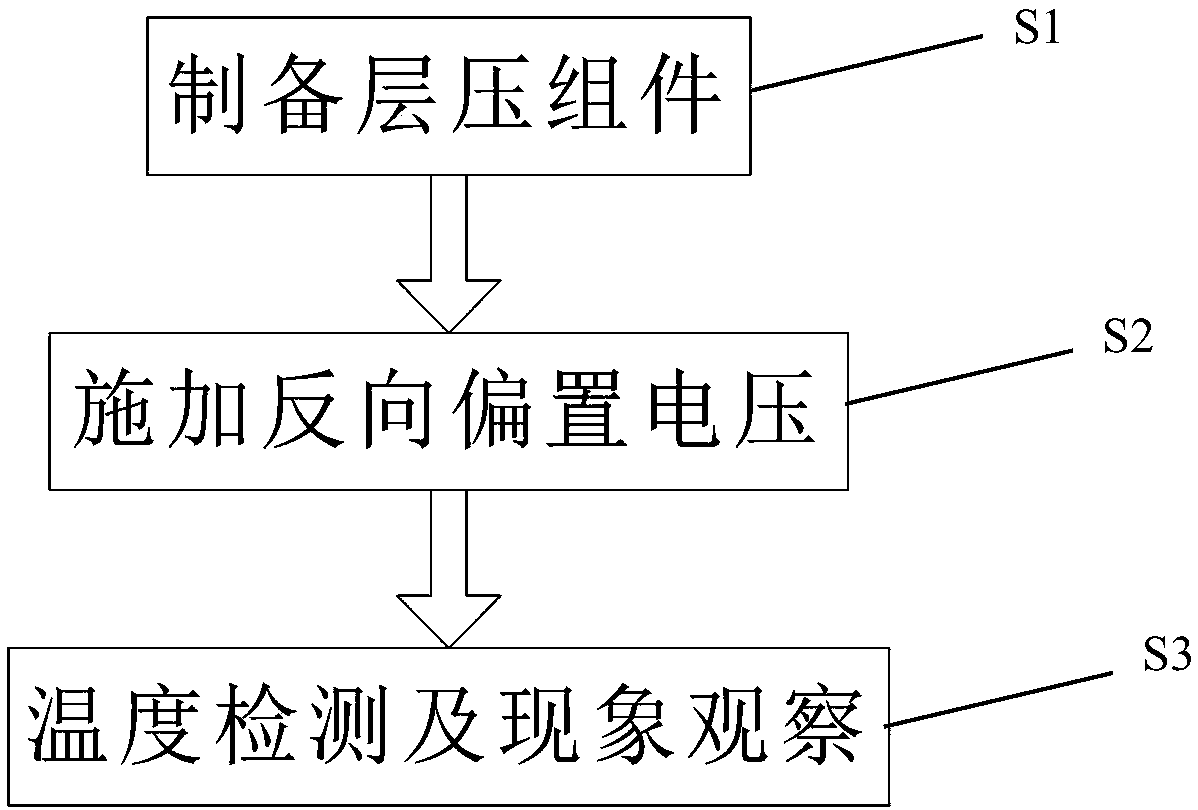

[0022] refer to Figures 1 to 2 , a kind of detection method of solar cell hot spot, specifically comprises the following steps:

[0023] Step S1: Preparation of Laminated Assembly

[0024] A battery sheet is first prepared into a laminated assembly. The preparation of laminated modules is basically the same as that of photovoltaic modules. The operation of preparing the laminated assembly in this embodiment is as follows: electrically connect a piece of battery sheet to the flow guide to form the battery layer 3, and cover the packaging material and the cover plate on the top and bottom of the battery layer 3 respectively to form a top cover from top to bottom. A laminated assembly with a structure of plate 1, front packaging material 2, battery layer 3, rear packaging material 4, and lower cover plate 5. In this embodiment, the flow guide is a welding strip, the upper cover 1 is made of glass, and the lower cover 2 is made of a polymer material, such as PET, PC or PMMA. ...

Embodiment 2

[0035] The detection method of a solar cell hot spot in this embodiment is basically the same as that in Embodiment 1, except that the temperature detection device in this embodiment is a temperature measuring gun. When using a temperature measuring gun for temperature detection, it is necessary to divide the laminated components into regions, monitor the temperature changes in each region and observe the phenomena generated by the laminated components to determine the specific location of the hot spots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com