UV curing device with gas protection

A technology of curing device and curing box, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of stickiness and non-drying, and achieve the solution of sticky and non-drying, continuous curing, and oxygen suppression. The effect of polymerization inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

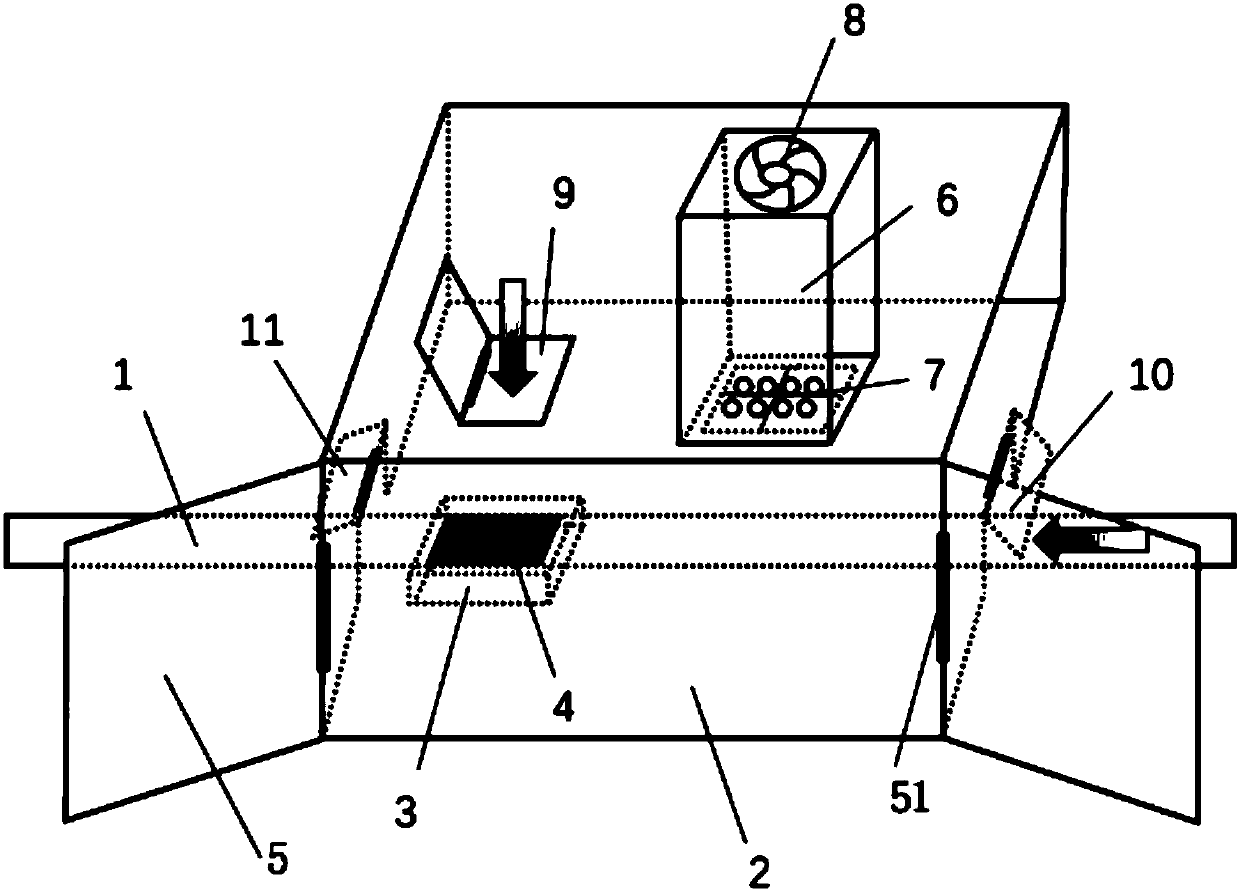

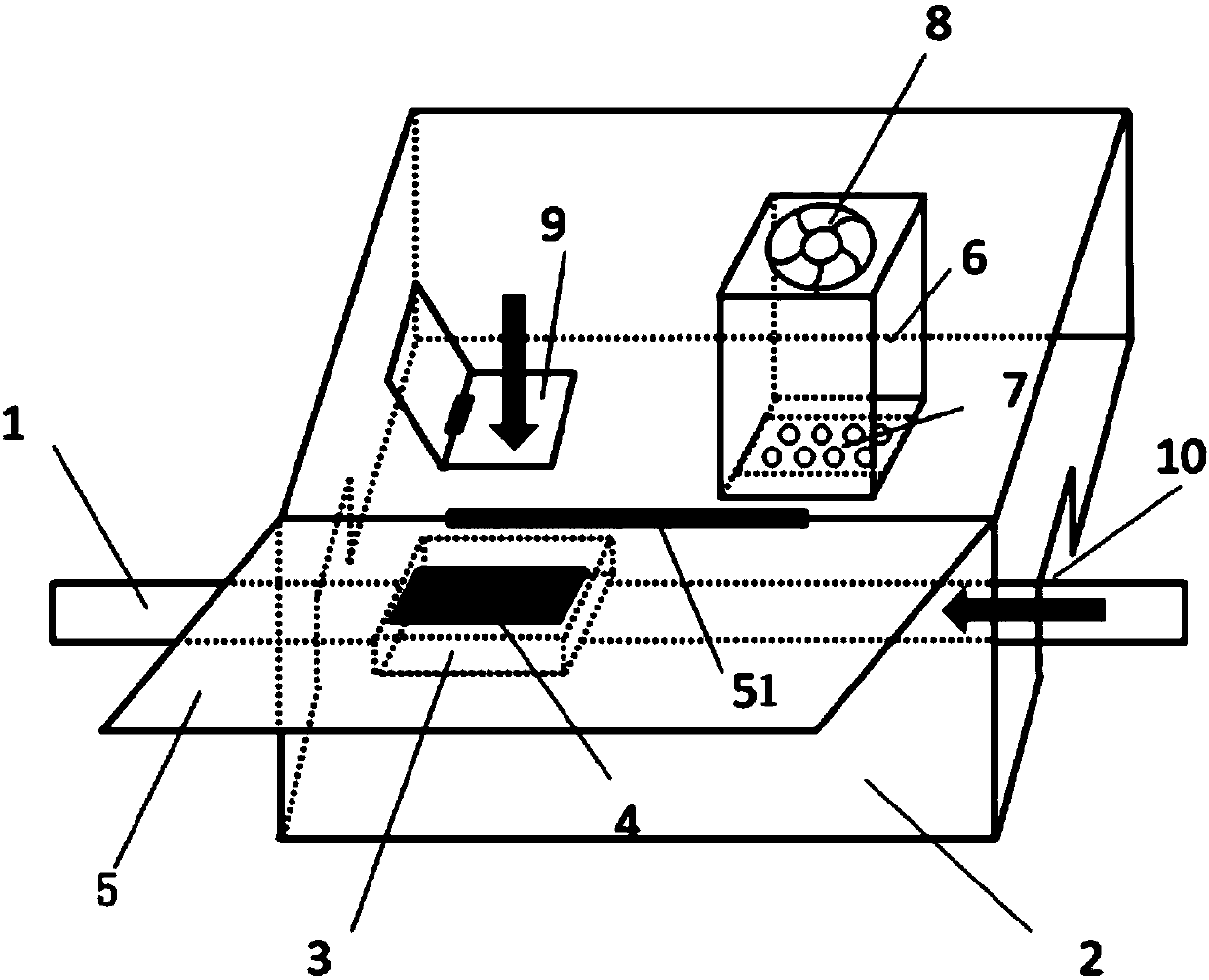

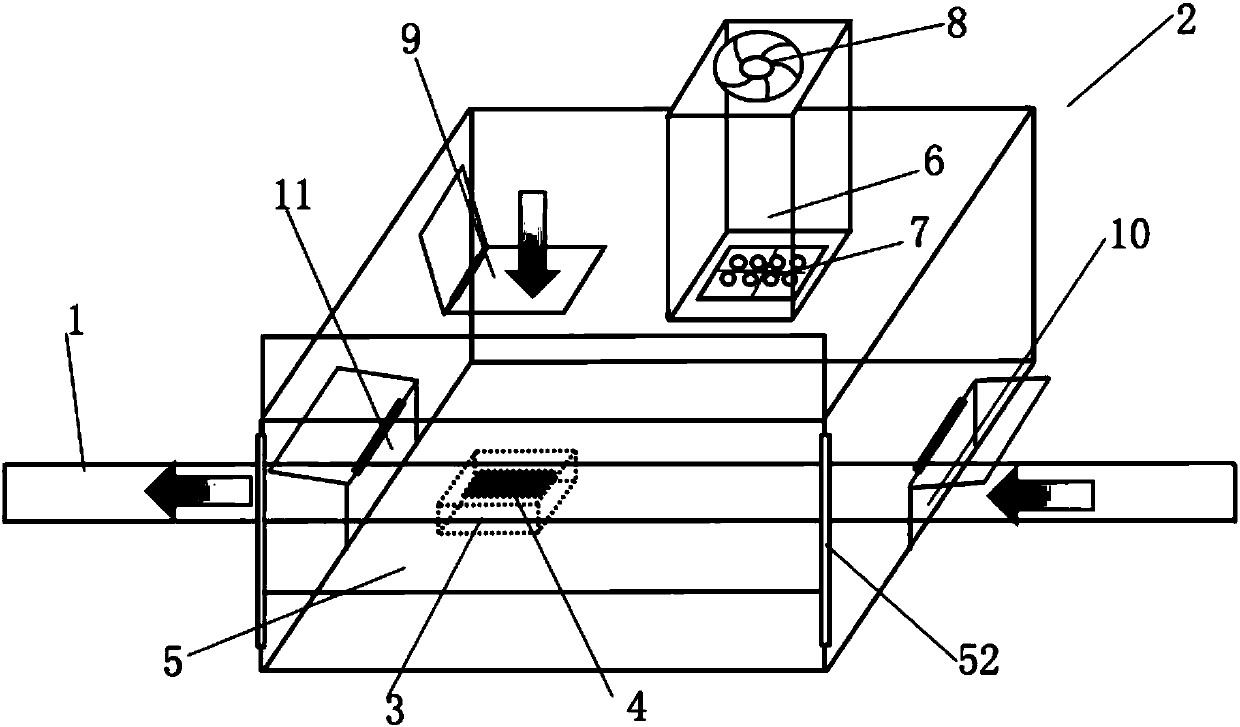

[0024] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

[0025] In order to achieve the above objectives, the technical solutions adopted by the present invention are as follows: Figure 1~4 As shown, a UV curing device with gas protection includes a semi-enclosed curing box 2, a transmission device, a material carrying device 4, and a UV curing light source device 6; the transmission device includes a synchronous conveyor belt 1 and a slider 3, and the slider 3 It is installed on the synchronous conveyor belt 1, the material carrying device 4 is placed on the slider 3, and the UV curing light source device 6 is installed on the upper wall of the semi-closed curing box 2. The semi-closed curing box 2 is provided with a vent, the protective gas enters the semi-closed curing box 2 through the vent, and the protective gas is nitrogen or carbon dioxide gas. The vent is a movable window. The vent includes a first ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com