Full-automatic conveying device for paper rolls

A transmission device, fully automatic technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of large volume and weight, low work efficiency, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

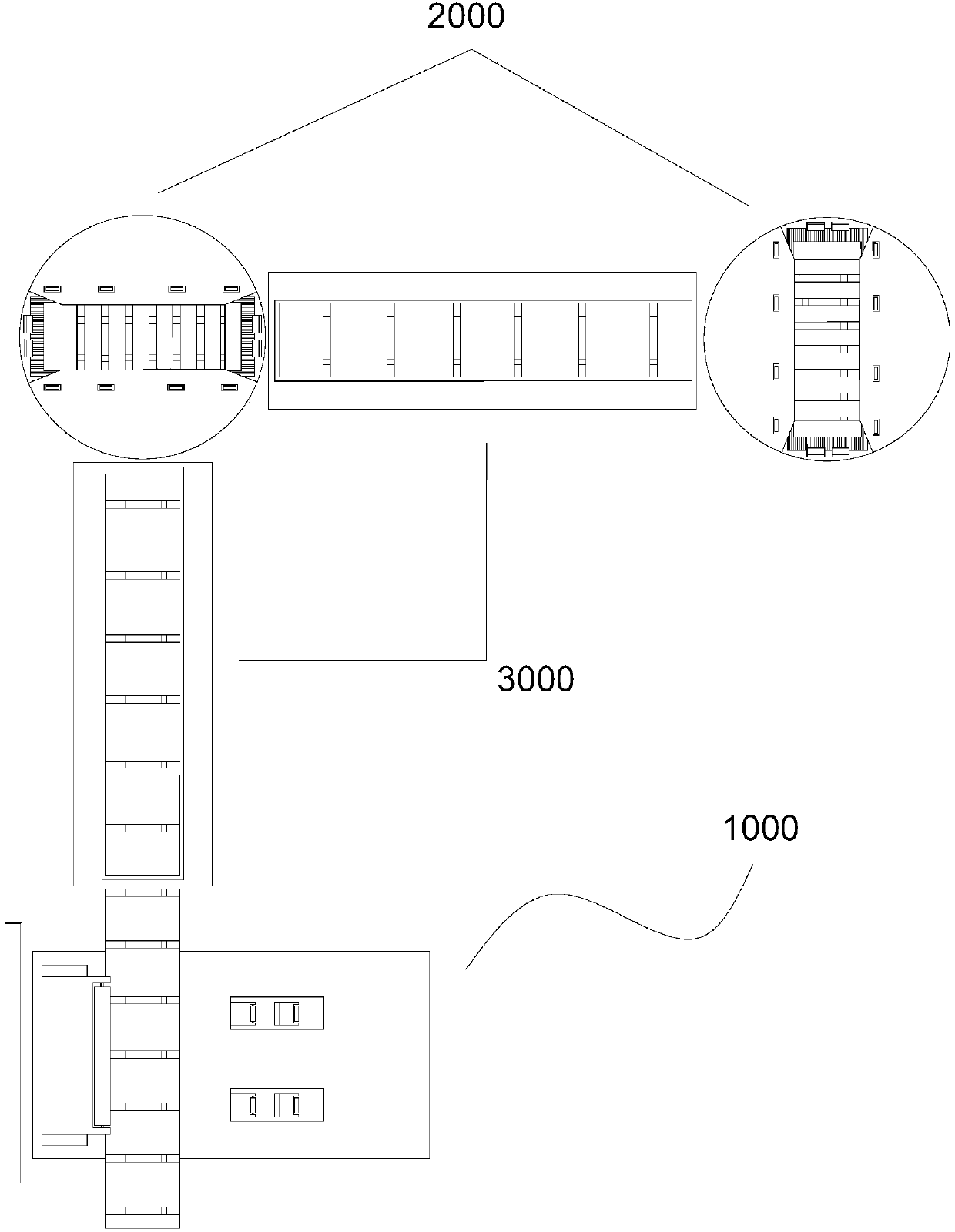

[0031] see figure 1 , a fully automatic paper tube transmission device, which includes: an automatic feeding part 1000, a direction changing transfer part 2000, and two adjacent direction changing transfer parts arranged between the automatic feeding part 1000 and the changing direction transfer part 2000 2,000 between 3,000 and 3,000 bridges. The automatic feeding part 1000, the direction changing transfer part 2000 and the bridge conveyor belt 3000 are all electrically connected with the circuit control system, and their actions are controlled by the circuit control system.

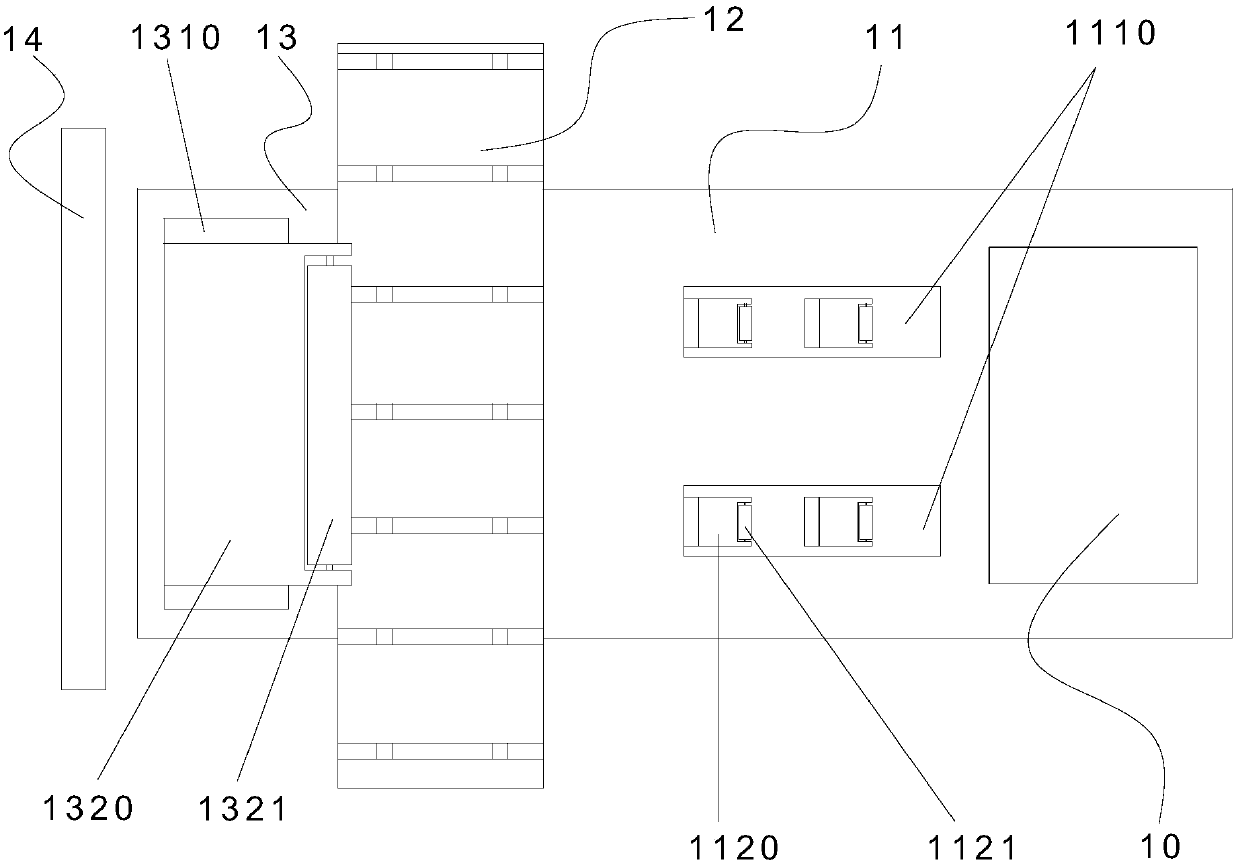

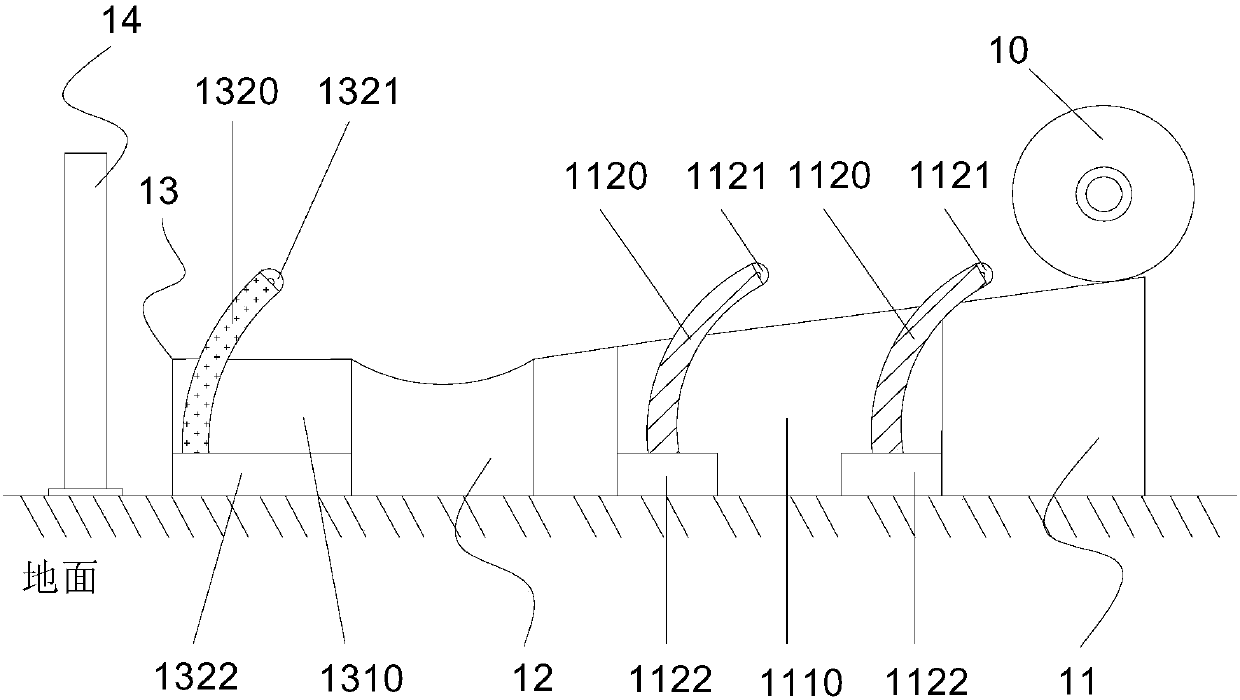

[0032] see figure 2 and image 3 , the automatic feeding part 1000 includes: the ramp plate 11 for discharging the paper tube 10, the upper end surface of which is provided with an opening 1110, and a retractable baffle 1120 is arranged in the opening 1110; the conveyor belt 12 is arranged on the ramp plate 11 Bottom and one side are adjacent to the slope plate 11; platform 13, which is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com