A vacuum rotary dryer for pvc cable material

A technology of vacuum rotation and dryer, which is applied in the direction of drying chamber/container, drying solid material, non-progressive dryer, etc. It can solve the problems of inconvenient and quick, single function of instruments and equipment, and the efficiency of production operation needs to be improved, so as to speed up Effect of drying speed, improving drying speed, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

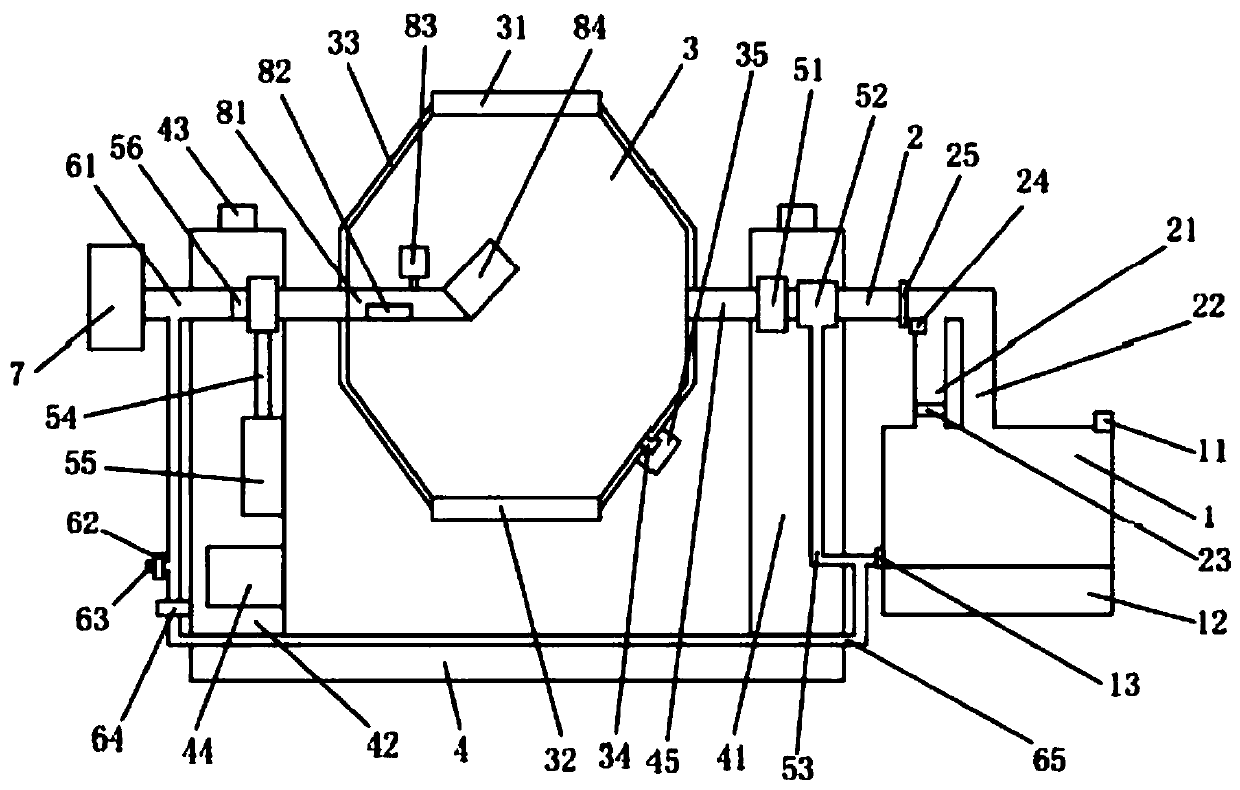

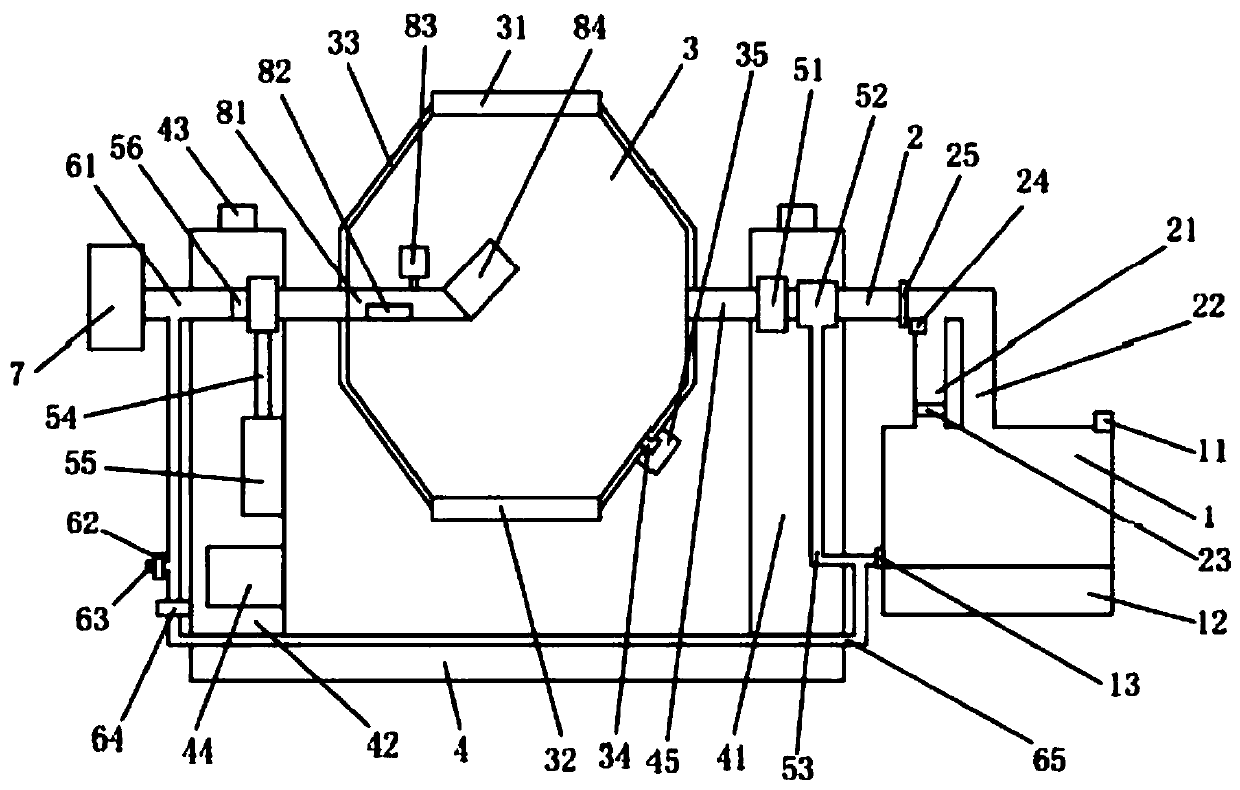

[0033] The present invention comprises a water tank 1, a water inlet 11, a heater 12, a recovery valve 13, a heat inlet connecting pipe 2, a heat inlet circulation pipe 21, a heat inlet pipe 22, a heat inlet circulation valve 23, a temperature sensor 24, a heat inlet Valve 25, tank body 3, material inlet 31, material outlet 32, interlayer 33, air release valve 34, air release valve cover 35, base 4, heat inlet connecting column 41, drying connecting column 42, alarm 43, control System 44, rotating connecting rod 45, rotating shaft 51, heat inlet 52, heat inlet recovery pipe 53, transmission belt 54, motor 55, angle sensor 56, output connecting pipe 61, exhaust valve 62, exhaust port 63, drying Recovery valve 64, drying recovery pipe 65, vacuum pump 7, drying connecting pipe 81, humidity sensor 82, vacuum gauge 83, filter 84;

[0034] One end of the top outside of the base 4 is provided with a dry connecting column 42, and the other end is provided with a heat-inlet connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com