Abrasive belt grinding product

A kind of abrasive belt and abrasive technology, which is applied in the field of conversion form, can solve the problems of inapplicability and rough surface structure of abrasive products, and achieve the effects of inhibiting the formation of streaks, good mechanical and topological properties, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Hereinafter, preferred embodiments are described in detail with reference to the accompanying drawings.

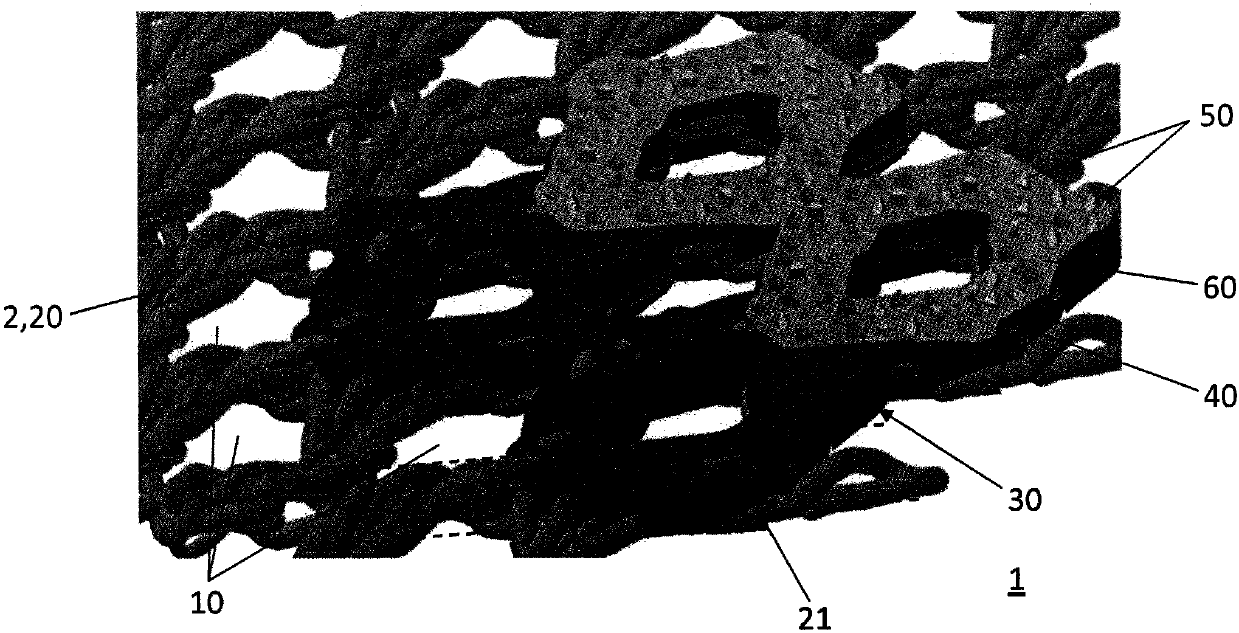

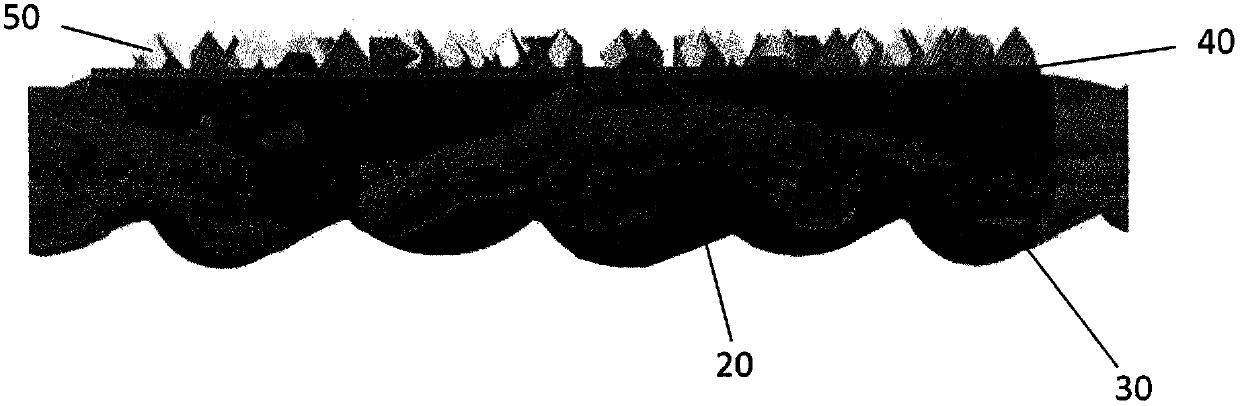

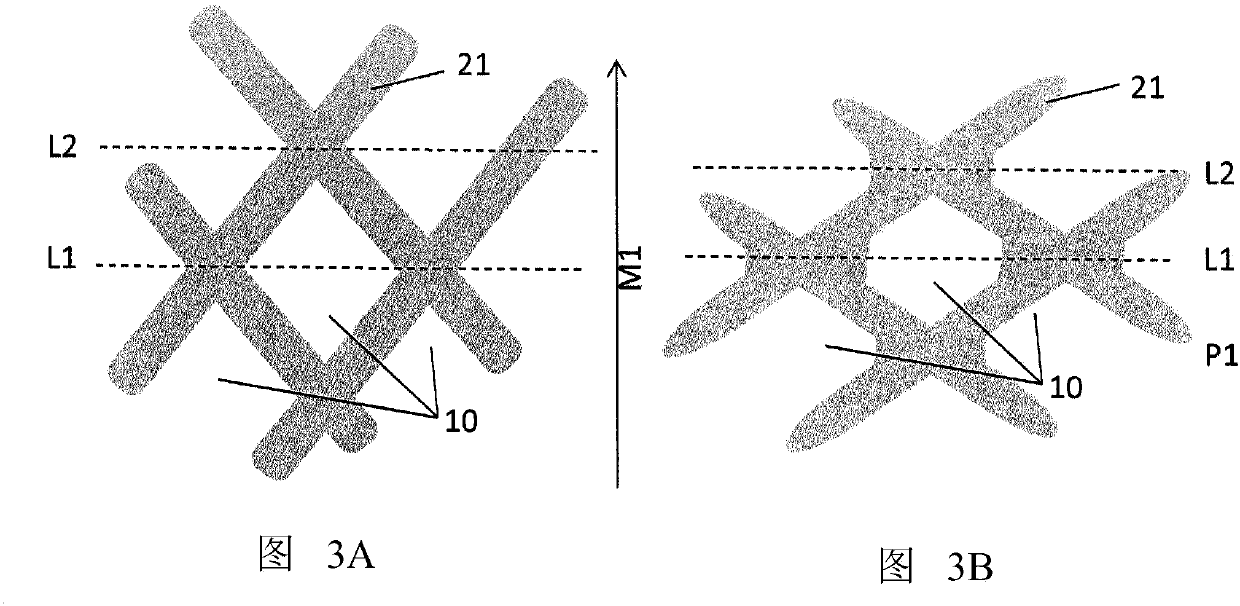

[0091] figure 1 A cross-section of a sanding belt 1 according to an embodiment is shown. figure 1 The different layers shown in show the abrasive belt 1 at different stages of the abrasive belt manufacturing process. It can be deduced from the first stage that the textile fabric 2 of the sanding belt 1 comprises a plurality of interconnected fabric threads 20 . Preferably, the textile fabric 2 has the form of a knitted textile fabric which can be produced, for example, by warp knitting on a fabric production machine. In a second stage, the textile fabric 2 is physically fixed by applying an impregnation 30 . In the third stage, the impregnated textile fabric 2 has been coated with a coating 40 . Further, abrasive material or grit 50 has been selectively applied by using a suitable hemming system. Thus, a continuous abrasive zone 60 is formed in which the abrasi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com