Spray pipe, membrane spray device and membrane spray system for preparing tubular nanofiltration membrane

The technology of a spraying device and a nanofiltration membrane is applied in the field of preparation systems for preparing tubular nanofiltration membranes by an interfacial polymerization method, and can solve the problems of increasing the membrane manufacturing cost and the amount of waste liquid, reducing the membrane flux, and the large amount of medicine, etc. Achieve the effect of shortening the production and assembly process, increasing the membrane flux, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the present invention clearer, a preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0034] The meaning of "inside and outside" in the present invention means that relative to the device itself, the direction pointing to the inside of the device is inside, and vice versa is outside. The meaning of "up and down" refers to the orientation of the device itself when the device is installed and used.

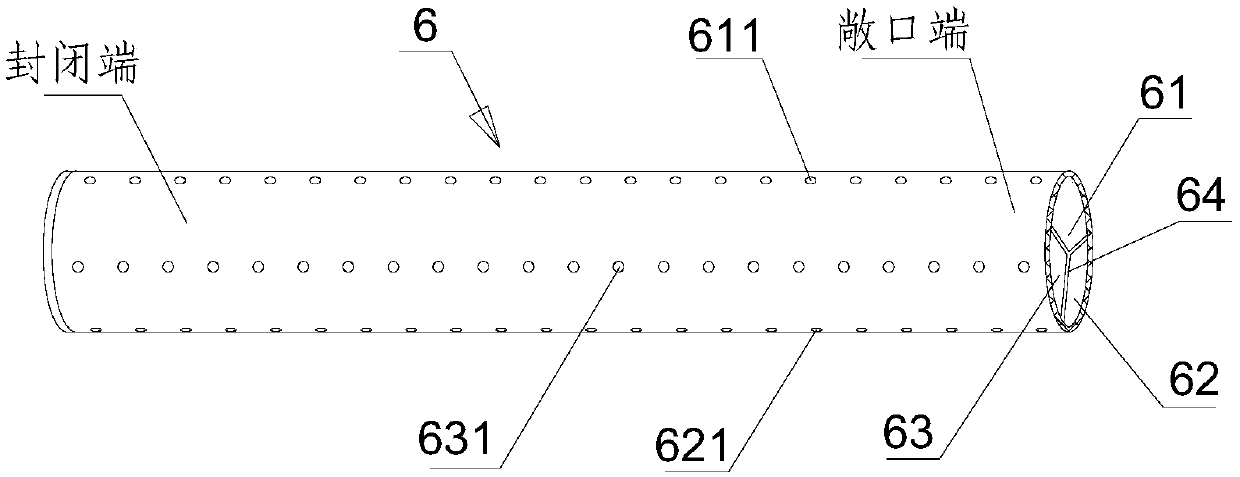

[0035] refer to figure 1 , a nozzle 6 for preparing a tubular nanofiltration membrane, one end of the nozzle is closed, the other end is open, and the open end is a liquid inlet end. The inside of the nozzle 6 is uniformly divided radially by three partitions 64 equal in length to the nozzle into three cavities that are not connected to each other, namely the water phase zone 61 , the oil phase zone 62 and the hot air zone 63 . The noz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole spacing | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com