Welding positioning device

A welding positioning and blocking technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as the impact of positioning tooling structure performance, the collision between welding head and product, and the inability to accurately position the product, so as to improve stability and The effect of using efficiency, improving quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the embodiments and drawings, which are only for explanation and not intended to limit the protection scope of the present invention.

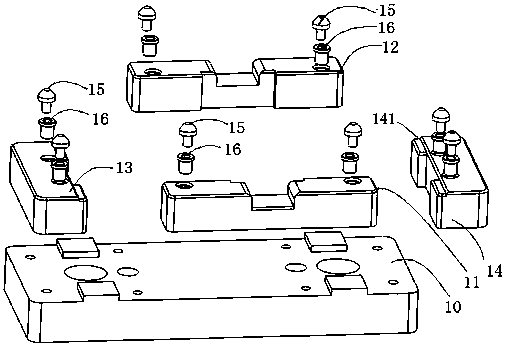

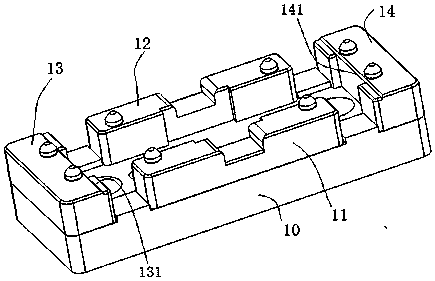

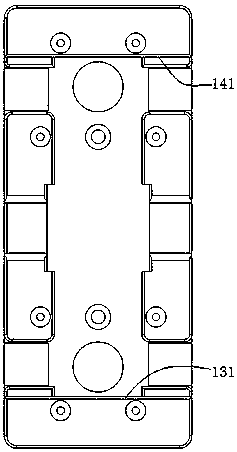

[0018] see Figure 1-4 , the welding positioning device of the present invention comprises a base 10, a front block 11, a rear block 12, a left block 13, and a right block 14 which are arranged on the base 10 in four directions, front, rear, left, and right; control unit. The left block and the right block are respectively connected to the control unit through lines, and the control unit receives the conduction signal of the left block and the right block to start the welding machine to work.

[0019] Wherein the base 10 is made of insulating material, usually made of plastic material. Each block is fixed on the corresponding position of the base with screws, and the screw holes on the base 10 are designed as elongated holes to facilitate the adjustment of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com