Machining method of steel member

A processing method and steel component technology, applied in the field of steel component processing, can solve problems such as deformation, weld cracking, and many welds, and achieve broad application prospects, improve pressure bearing capacity, and optimize pressure bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

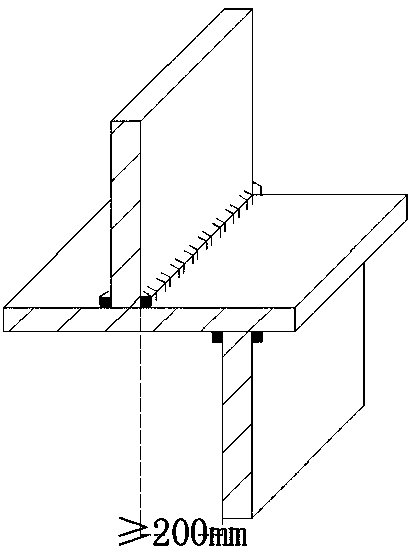

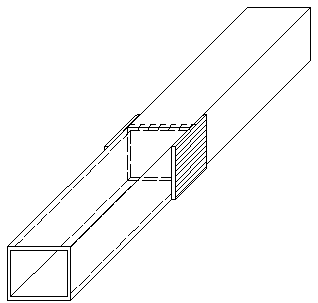

[0037]Embodiment: First, determine the number of required steel components according to the requirements of the drawings. The steel components involved in processing are greater than or equal to two pieces, and compare them with the parameters of the drawings one by one according to the size specifications of the specific steel components to ensure that the steel components used meet the processing requirements. The stakeout should use a steel ruler that has passed the metrological verification, and the calibrated deviation value should be included in the measurement size. The size planning method should first measure the full length and then divide the size, and do not add up the measurements in sections to avoid the accumulation of deviations. The number of materials is based on the model As a basis, draw the real sample on the material and mark it with various processing marks. The sample material should use the sample that has passed the inspection to avoid unnecessary losse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com